A centrifugal force pendulum with a damper

A technology of centrifugal force pendulum and pendulum flange, applied in the field of centrifugal force pendulum, can solve the problem of reducing the swing stroke, and achieve the effect of reducing the risk of breaking, simple and effective vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

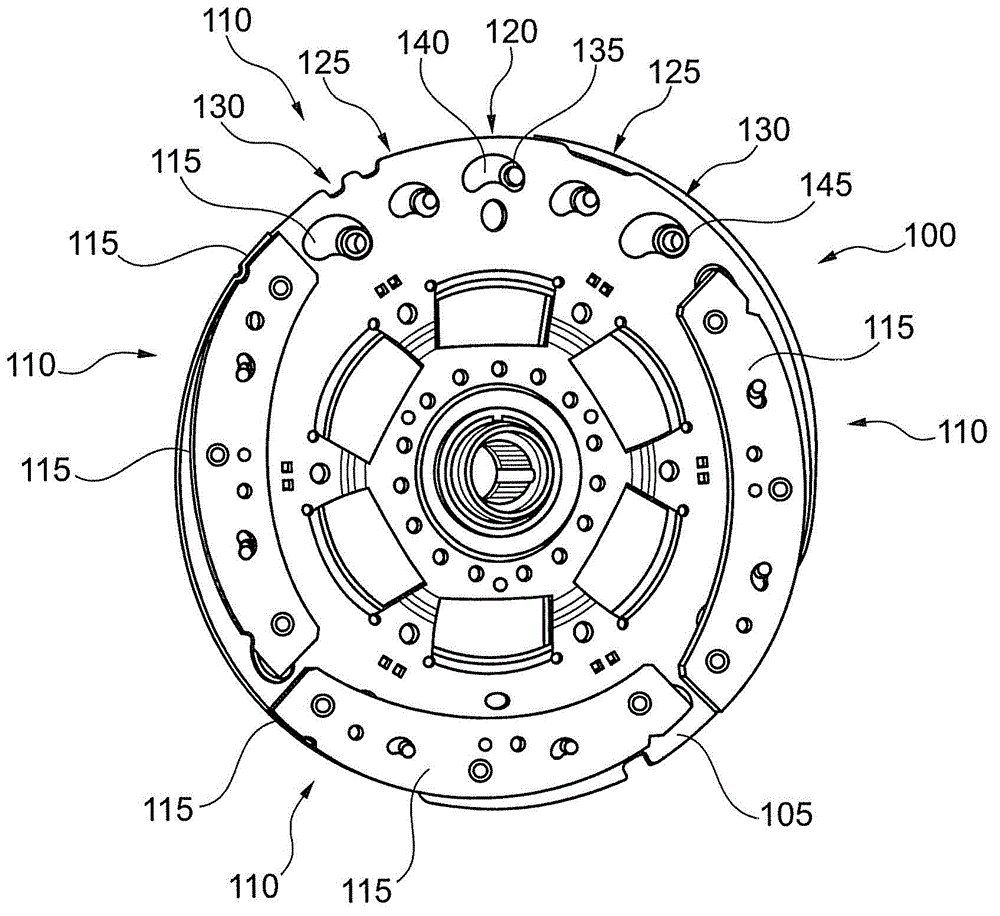

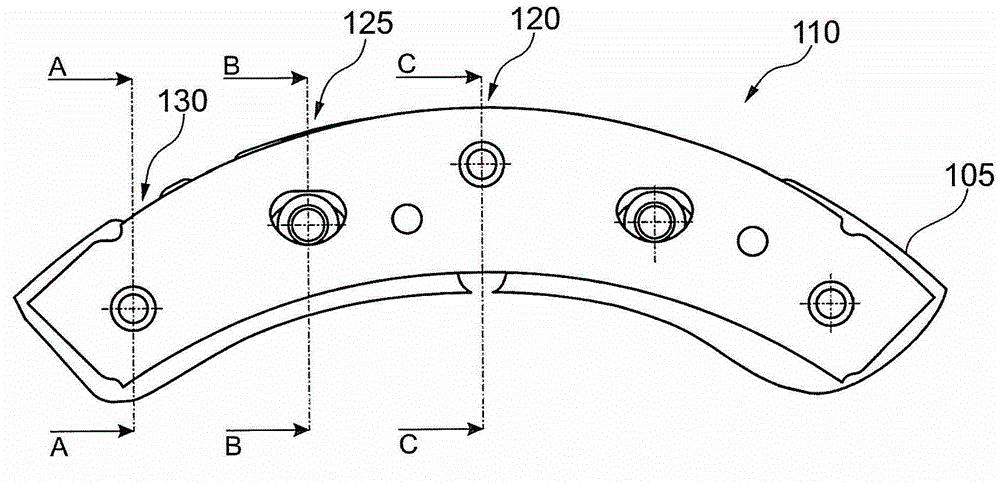

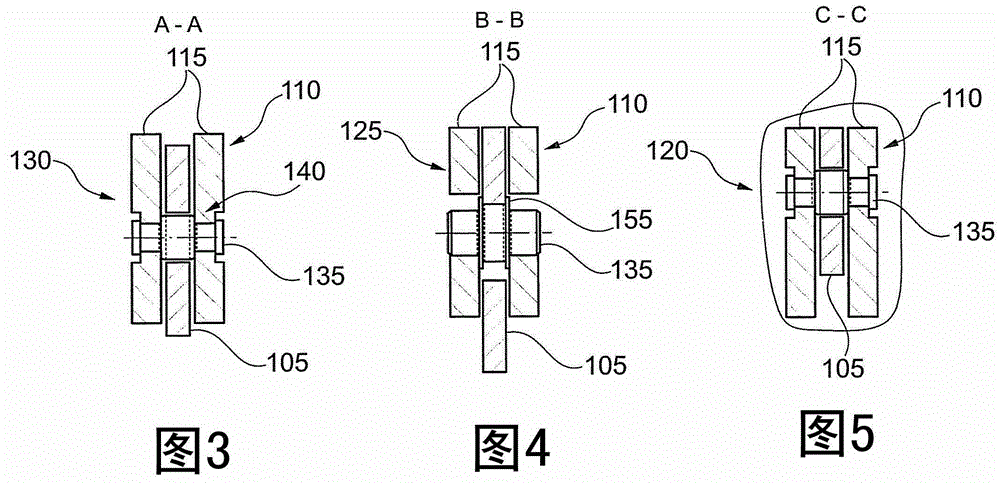

[0023] figure 1 A mass damper with a centrifugal pendulum 100 is shown. The centrifugal pendulum 100 includes a pendulum flange 105 which is arranged rotatably about an axis which transmits torque in a drive train. The drive train may include, inter alia, the drive motor and the transmission of the vehicle. Centrifugal force pendulum 100 also comprises four pendulum masses 110, in figure 1 Only three of them are fully shown in . Each pendulum mass 110 includes two mass elements 115 which are situated on different axial sides of the pendulum flange 105 . On the upper pendulum mass 110 , the mass element 115 facing the observer has been removed for a clearer illustration.

[0024] The mass elements 115 of each pendulum mass 110 are fixed on the pendulum flange 105 by means of a central link guide 120 , two inner link guides 125 and two outer link guides 130 in such a way that the pendulum masses 110 can Pivots in the plane of rotation of the pendulum flange 105 . Each link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com