An automatic stamping machine for engineering drawings

A technology of automatic stamping machine and engineering drawings, applied in printing, stamping and other directions, which can solve the problems of heavy engineering-related responsibilities, low efficiency, and large amount of engineering drawings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

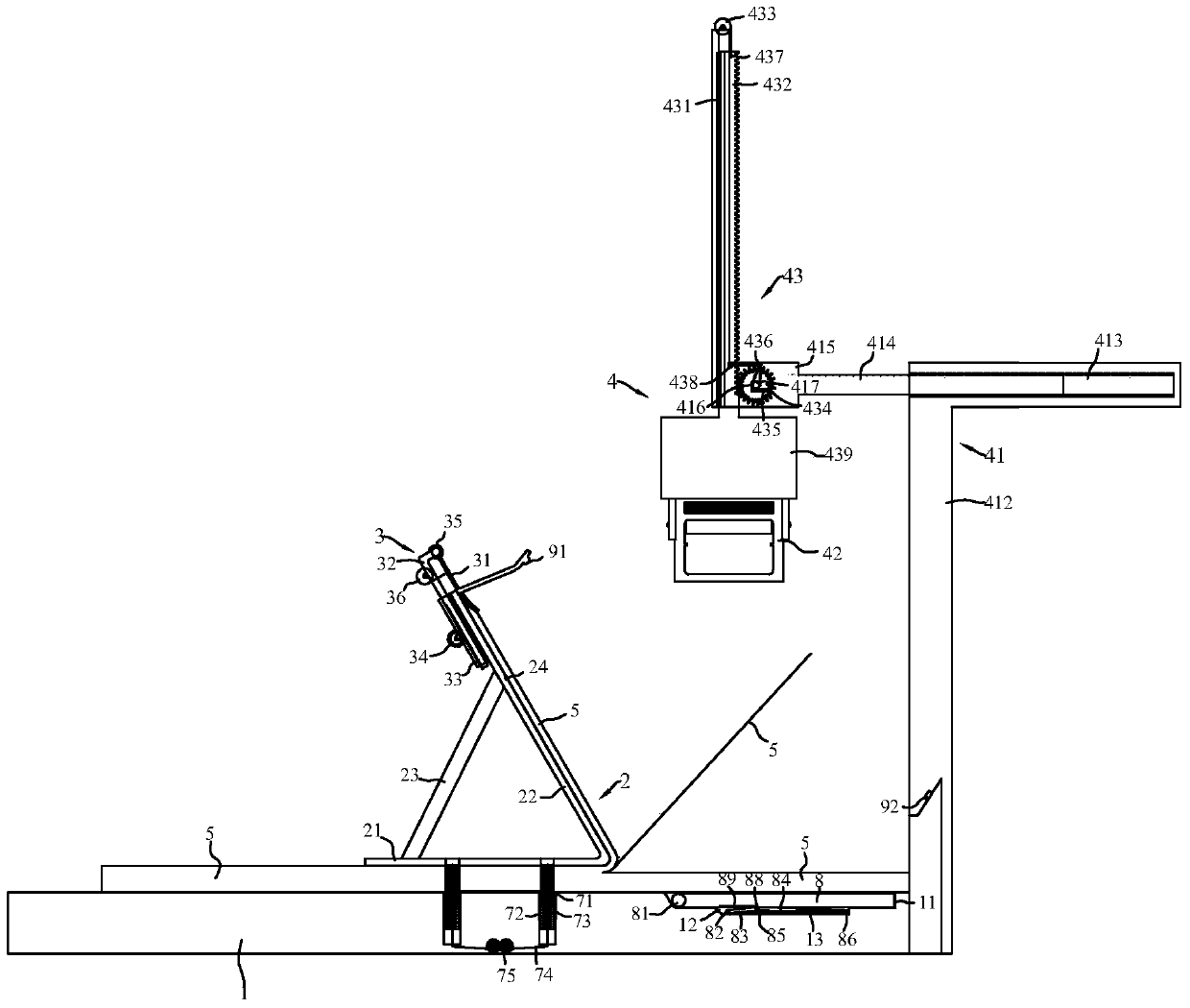

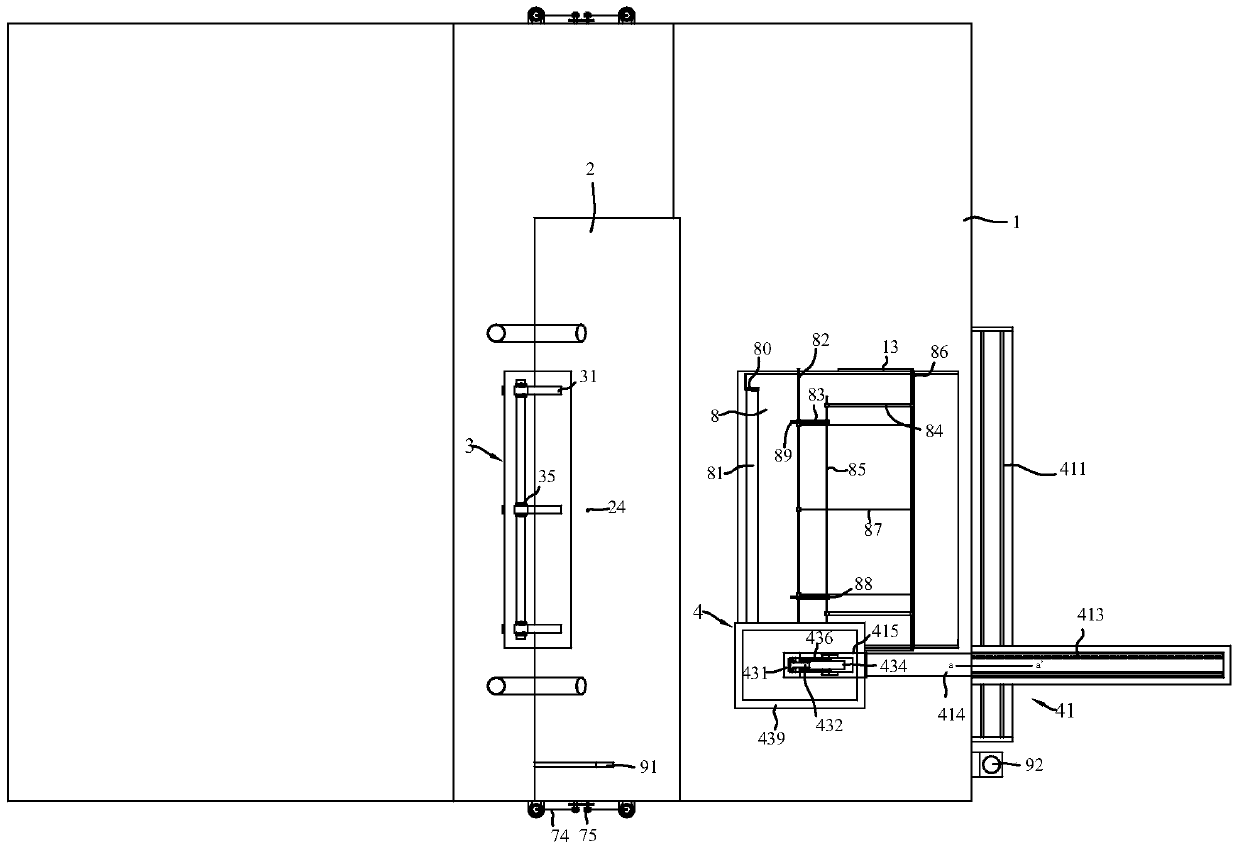

[0028] refer to Figure 1 to Figure 5 , which shows the specific structure of the preferred embodiment of the present invention. The structural features of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 1 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0029] refer to Figure 1-Figure 3, the present invention provides an automatic stamping machine for engineering drawings, including a working platform 1, a splint 2, a page turner 3 and a stamping device 4, the size of the working platform 1 is designed according to the size of the A1 drawing, and can be designed according to the needs , work platform 1 adds table legs and makes table platform shape separately, also can be equipped with some fixing clips and be fixed on existing table, platform. The supporting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com