A kind of preparation method of pedot highly conductive flexible paper material

A technology of flexible paper and high conductivity, which is applied in the field of preparation of PEDOT high conductivity flexible paper materials, can solve the problems of low resource utilization and difficulties, and achieve high rate performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of PEDOT highly conductive flexible paper material, specifically comprising the following steps:

[0020] (1) In a 25mL beaker, accurately weigh 0.8110g of anhydrous ferric chloride powder, then add 5mL of absolute ethanol, stir and ultrasonically disperse until the oxidant is completely dissolved to obtain a yellow oxidant solution;

[0021] (2) Cut a piece of 3×3cm cellulose paper;

[0022] (3) Soak the cellulose paper in the above-mentioned oxidant solution for 10 minutes, take it out and dry it naturally;

[0023] (4) Put the cellulose paper soaked in oxidant into a sealed container filled with EDOT monomer, and perform gas phase polymerization for 3 hours to obtain PEDOT highly conductive flexible paper.

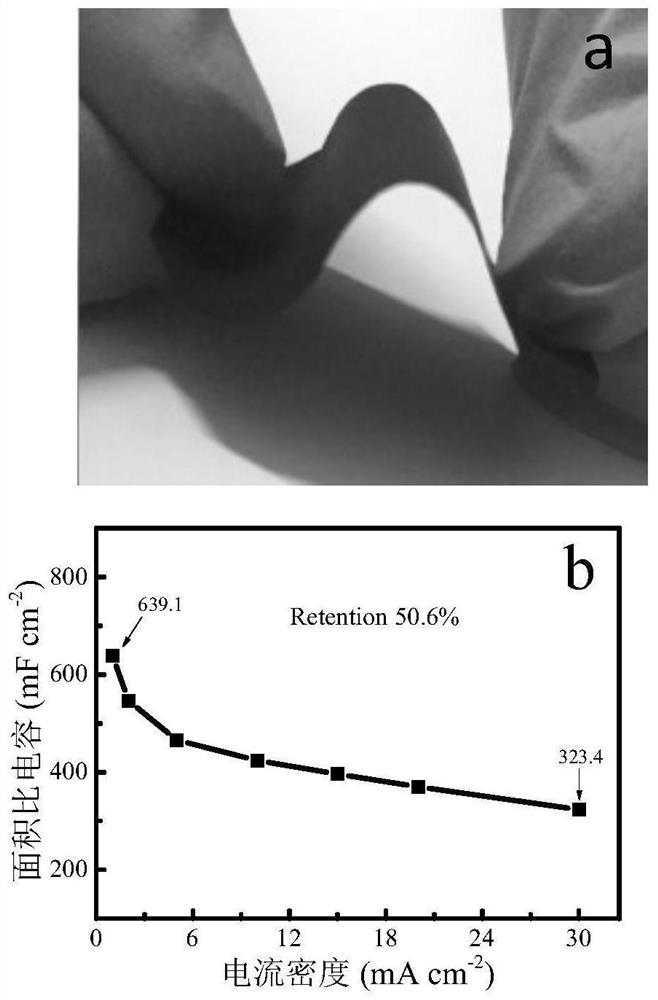

[0024] Such as figure 1 As shown in (a), the prepared PEDOT paper can be bent, indicating that it has certain flexibility.

[0025] The PEDOT highly conductive flexible paper that above-mentioned step (4) obtains is further processed to ca...

Embodiment 2

[0031] A preparation method of PEDOT highly conductive flexible paper material, specifically comprising the following steps:

[0032] (1) In a 25mL beaker, accurately weigh 2.8472g of iron p-toluenesulfonate powder, then add 5mL of absolute ethanol, stir and ultrasonically disperse until the oxidant is completely dissolved to obtain a yellow oxidant solution;

[0033] (2) Cut a piece of 3×3cm cellulose paper;

[0034] (3) Soak the cellulose paper in the above-mentioned oxidant solution for 10 minutes, take it out and dry it naturally;

[0035] (4) Put the cellulose paper soaked in oxidant into a sealed container filled with EDOT monomer, and perform gas phase polymerization for 3 hours to obtain PEDOT highly conductive flexible paper.

Embodiment 3

[0037] A preparation method of PEDOT highly conductive flexible paper material, specifically comprising the following steps:

[0038] (1) In a 25mL beaker, accurately weigh 1.3662g of molybdenum pentachloride powder, then add 5mL of absolute ethanol, stir and ultrasonically disperse until the oxidant is completely dissolved to obtain a dark green oxidant solution;

[0039] (2) Cut a piece of 3×3cm cellulose paper;

[0040] (3) Soak the cellulose paper in the above-mentioned oxidant solution for 10 minutes, take it out and dry it naturally;

[0041] (4) Put the cellulose paper soaked in oxidant into a sealed container filled with EDOT monomer, and perform gas phase polymerization for 3 hours to obtain PEDOT highly conductive flexible paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com