Anodic rare-earth oxide membrane closing method of aluminium alloy

An anodic oxidation film, anodic oxidation technology, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of high energy consumption, short processing time, and increased cost, and achieve simple maintenance, low solubility, and consumption The effect of less heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 The rare earth sealing method of anodic oxidation film of wrought aluminum alloy.

[0030] (1) Material: Forged aluminum alloy adopts national standard LD7 aluminum alloy.

[0031] (2) Anodizing treatment: polish the test piece, wash it with alkali to remove oil, and put it in a sulfuric acid solution (mass concentration of 250g / l) at 2A / dm 2 Oxidation by electric current for 1 hour, cleaning with deionized water, and observing with a scanning electron microscope, it can be seen that an anodic oxide film with a film thickness of about 20 microns is obtained.

[0032] (3) sealing treatment: according to the operating steps of the sealing method of the present invention, 1 gram of Nd 2 (CO 3 ) 3 and 1 g La 2 (CO 3 ) 3 Add 1 liter of water to make Nd 2 (CO 3 ) 3 and La 2 (CO 3 ) 3 Blocking solution for supersaturated aqueous solutions. The aluminum alloy sealed anodic oxidation film was obtained under the conditions of temperature 95°C and sealing ti...

Embodiment 2

[0035] Example 2 Rare-earth sealing method of anti-rust aluminum alloy anodized film.

[0036] The aluminum alloy adopts the anti-rust aluminum alloy of the national standard LF21 aluminum alloy. Anodizing treatment: the sulfuric acid solution used has a mass concentration of 200g / l to obtain an anodized film of 18 microns. All the other operating methods and process conditions are the same as in Example 1. The obtained polarization curve is shown as curve a in Fig. 2 .

[0037] The present embodiment compares with comparative example 3, comparative example 4, as can be seen from Fig. 2, the closed anodic oxide film that the present embodiment obtains is all smaller than the passive current of potassium dichromate and boiling water sealing, and this just illustrates the sealing of the present invention The oxide film has higher corrosion resistance.

Embodiment 3

[0038] Example 3 Rare earth sealing method of anodic oxidation film of cast aluminum alloy.

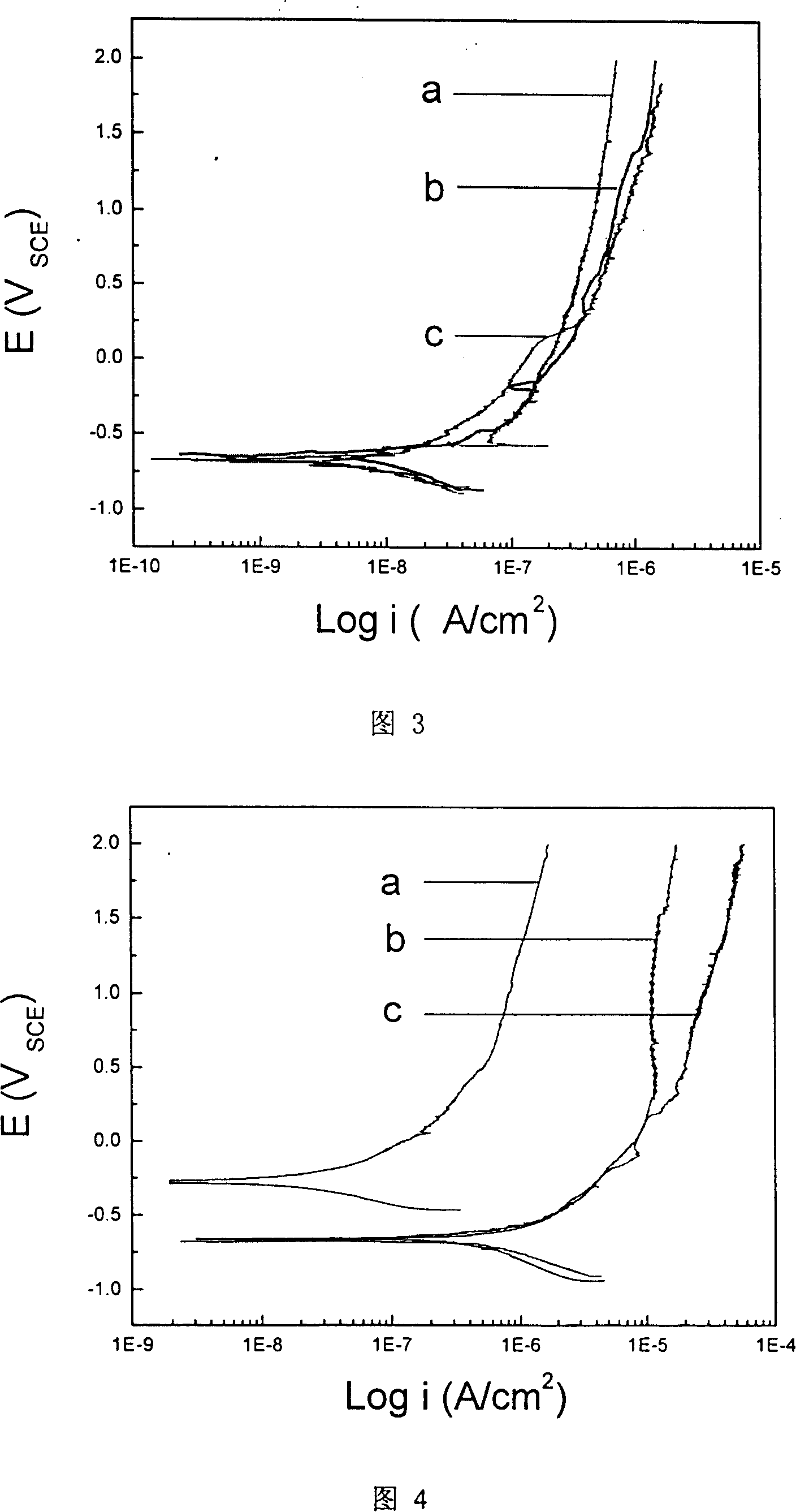

[0039] The aluminum alloy adopts the cast aluminum alloy of national standard ZL201. Anodizing treatment: the sulfuric acid solution used has a mass concentration of 150g / l to obtain an aluminum anodic oxidation film of 15 microns. All the other operating methods and process conditions are the same as in Example 1. The obtained polarization curve is shown in Fig. 3 a curve.

[0040] The present embodiment is compared with comparative example 5 and comparative example 6. As can be seen from Fig. 3, the closed anodic oxide film obtained in this embodiment is smaller than the passive current of potassium dichromate and boiling water sealing, which shows that the closed anodized film of the invention Membrane corrosion resistance is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com