A device for containing a die of a calibrating workpiece and a pressing mechanism thereof

A technology of presses and molds, applied in the field of mold devices, can solve problems such as failure to modularize, complex workpieces, and undiscovered problems, and achieve the effect of reducing the time for changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

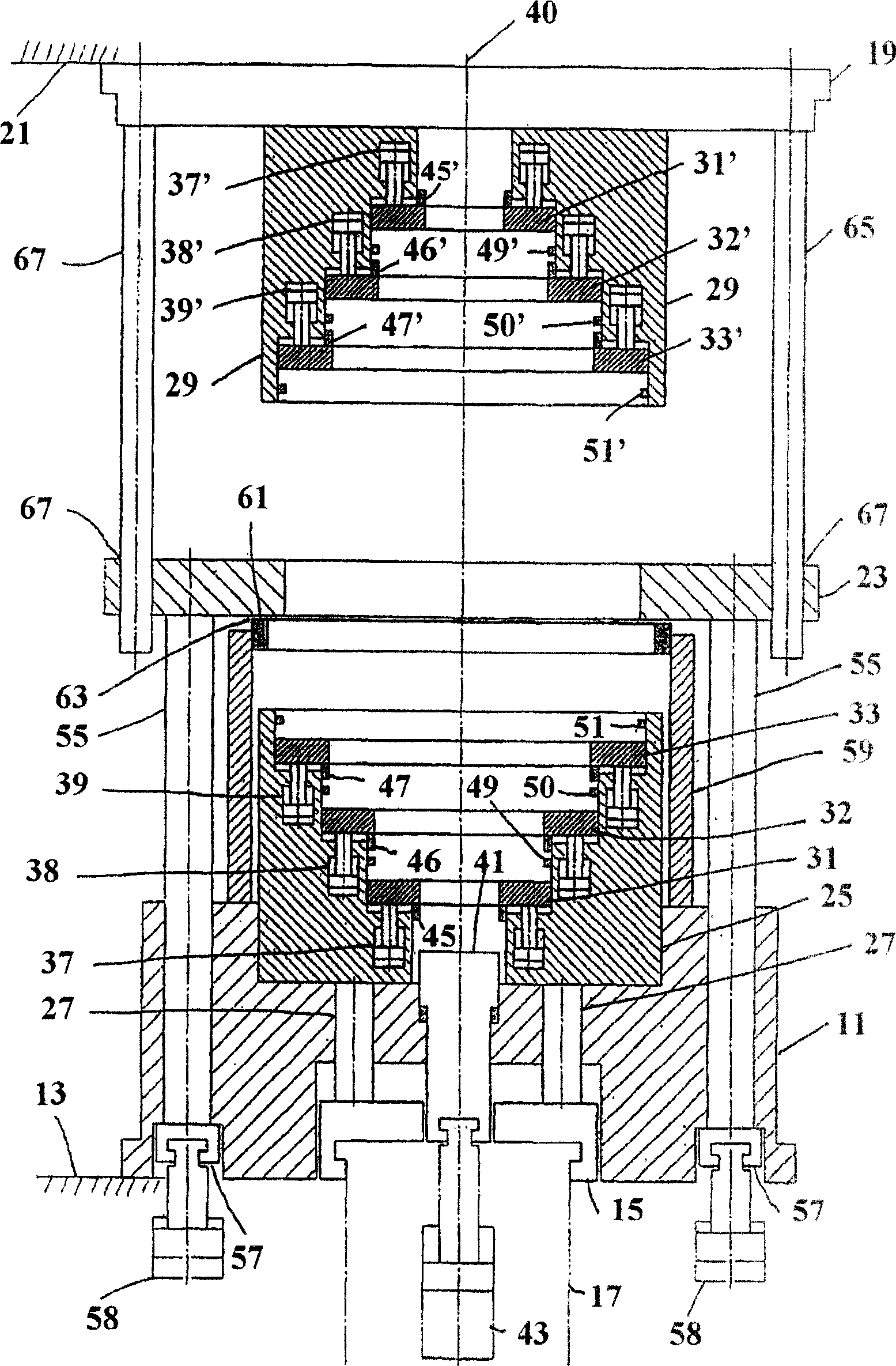

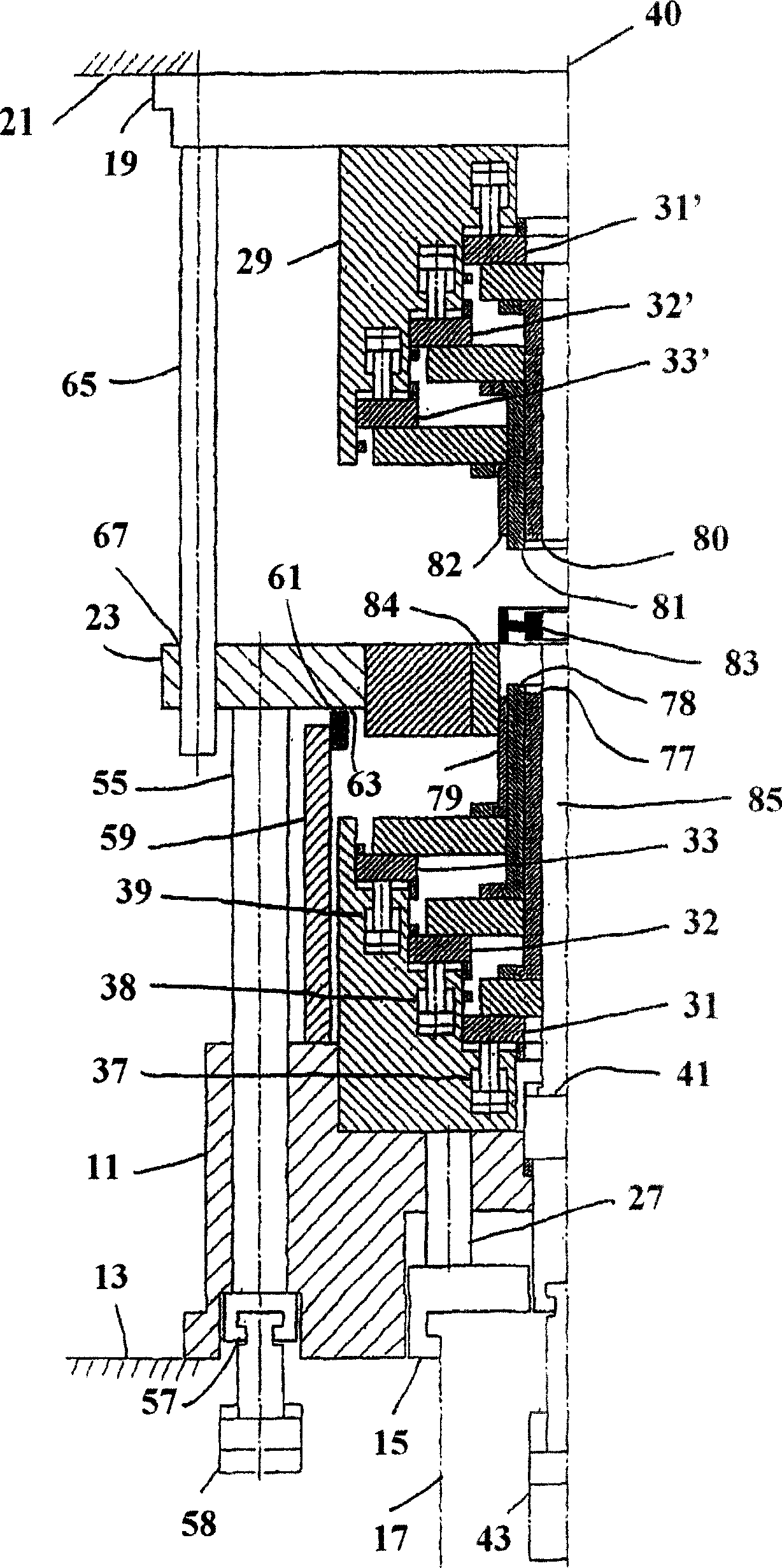

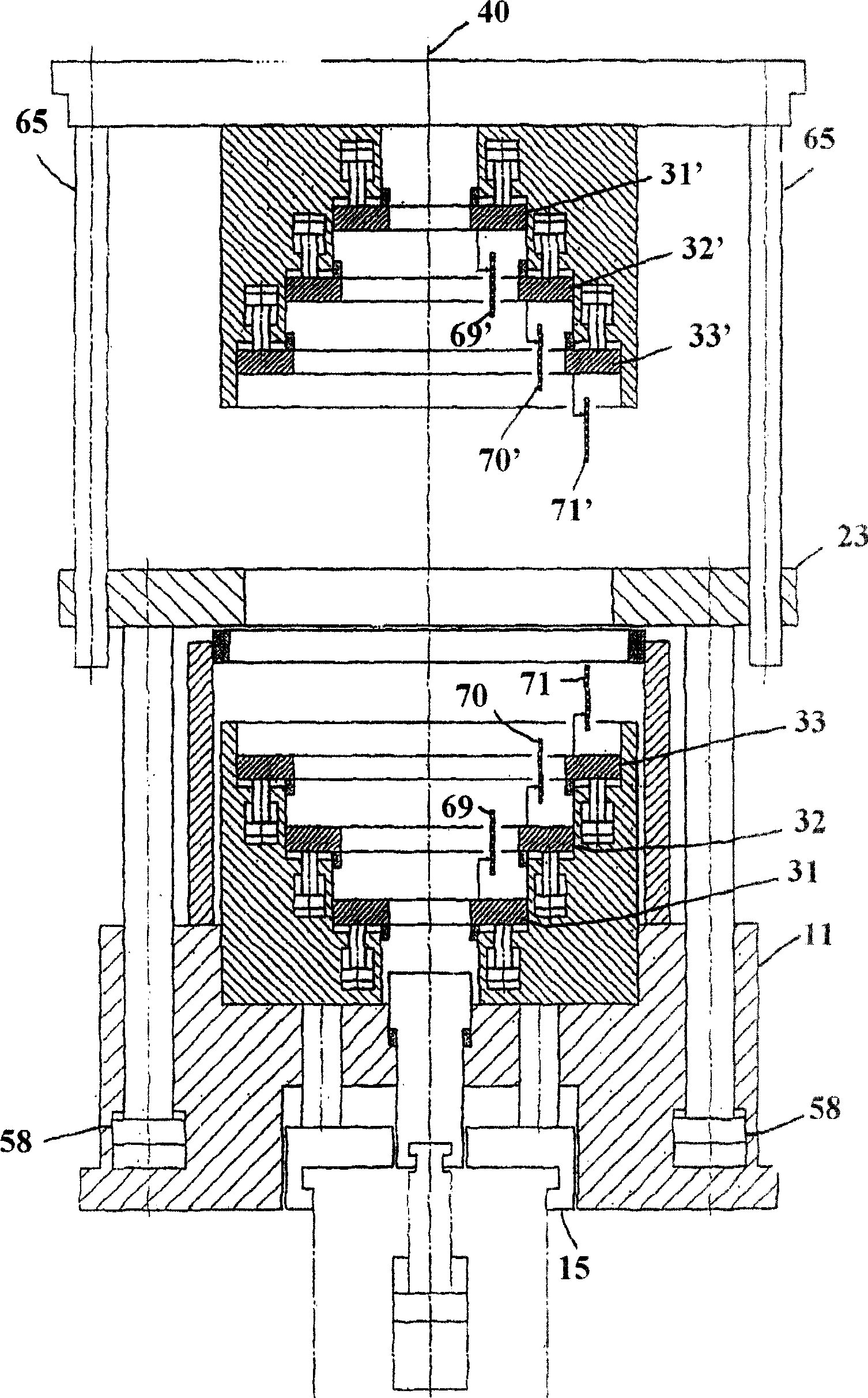

[0018] like figure 1 and figure 2 As shown, the device comprises a base plate 11, such as a square shape, for mounting to a platform 13 of a press, a lower connecting plate 15 fixed to the extrusion piston or lower ram 17 of the press, and an upper connecting plate 19 fixed to the Press head 21 on. The mold support plate 23 is located in the space between the base plate 11 and the upper connection plate 19 .

[0019] The lower mold accommodating unit 25 is connected to four rods 27 to be connected to the connecting plate 15 . The upper mold accommodating unit 29 is connected to the upper connection plate 90 . The lower mold receiving unit 25 comprises three mold supports 31 , 32 , 33 which can be moved back and forth individually or together by actuating mechanisms parallel to the axis 40 , such as hydraulic cylinders 37 , 38 , 39 . In the embodiment shown, the actuating mechanisms 37, 38, 39 are integrally formed with the mold containing unit. The mold supports 31, 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com