Compressor with muffler

A compressor and muffler technology, applied in the field of scroll compressors, can solve problems such as noise motor, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description is merely exemplary in nature and is not intended to limit the present teachings, application, or uses.

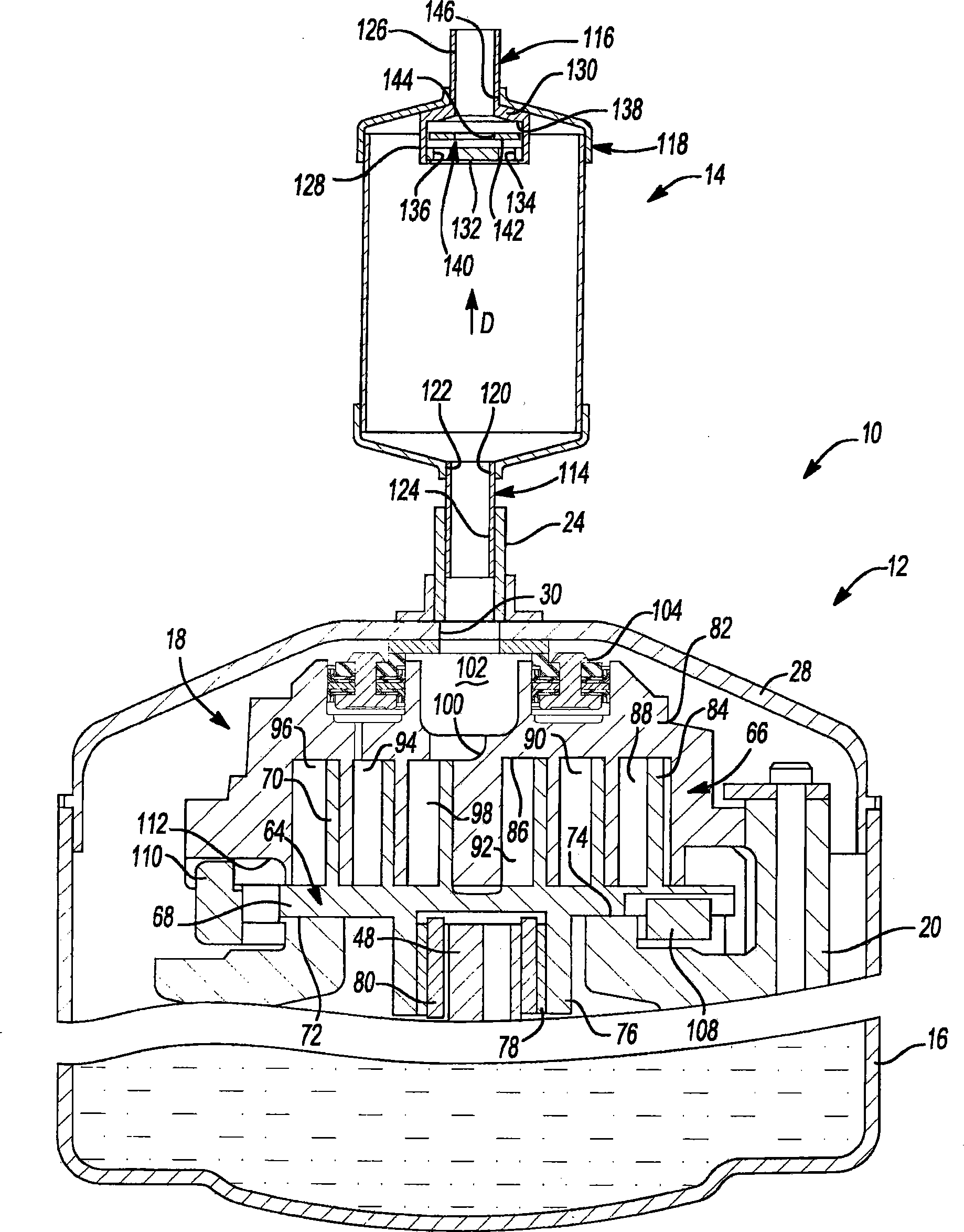

[0027] The present teachings are suitable for incorporation in many different types of scroll and rotary compressors, including hermetic, open drive and non-hermetic machines. For exemplary purposes, a compressor assembly 10 is shown comprising a low side hermetic scroll refrigerant motor compressor 12, i.e., where the motor and compressor are cooled by suction air in a hermetic enclosure, as in figure 1 , 2 , 4 and 5 are shown in vertical section.

[0028] Such as figure 1 and 2 As shown, the compressor assembly 10 includes a compressor 12 and an external muffler assembly 14 . Compressor 12 may include a cylindrical hermetic housing 16 , a compression mechanism 18 , a main bearing housing 20 , a motor assembly 22 , a refrigerant discharge fitting 24 and a suction inlet fitting 26 . Sealed housing 16 may house compression mechanism 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com