Dry ice particle spraying device

A spraying device and particle technology, which is applied in the direction of spraying device, spraying device, liquid spraying device, etc., can solve the problems of easily damaged items, inability to obtain sufficient cleaning effect, troubles, etc., and achieve high-efficiency spraying, high-efficiency sandblasting or cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, the present invention will be described in detail with reference to the embodiments of the present invention shown in the drawings.

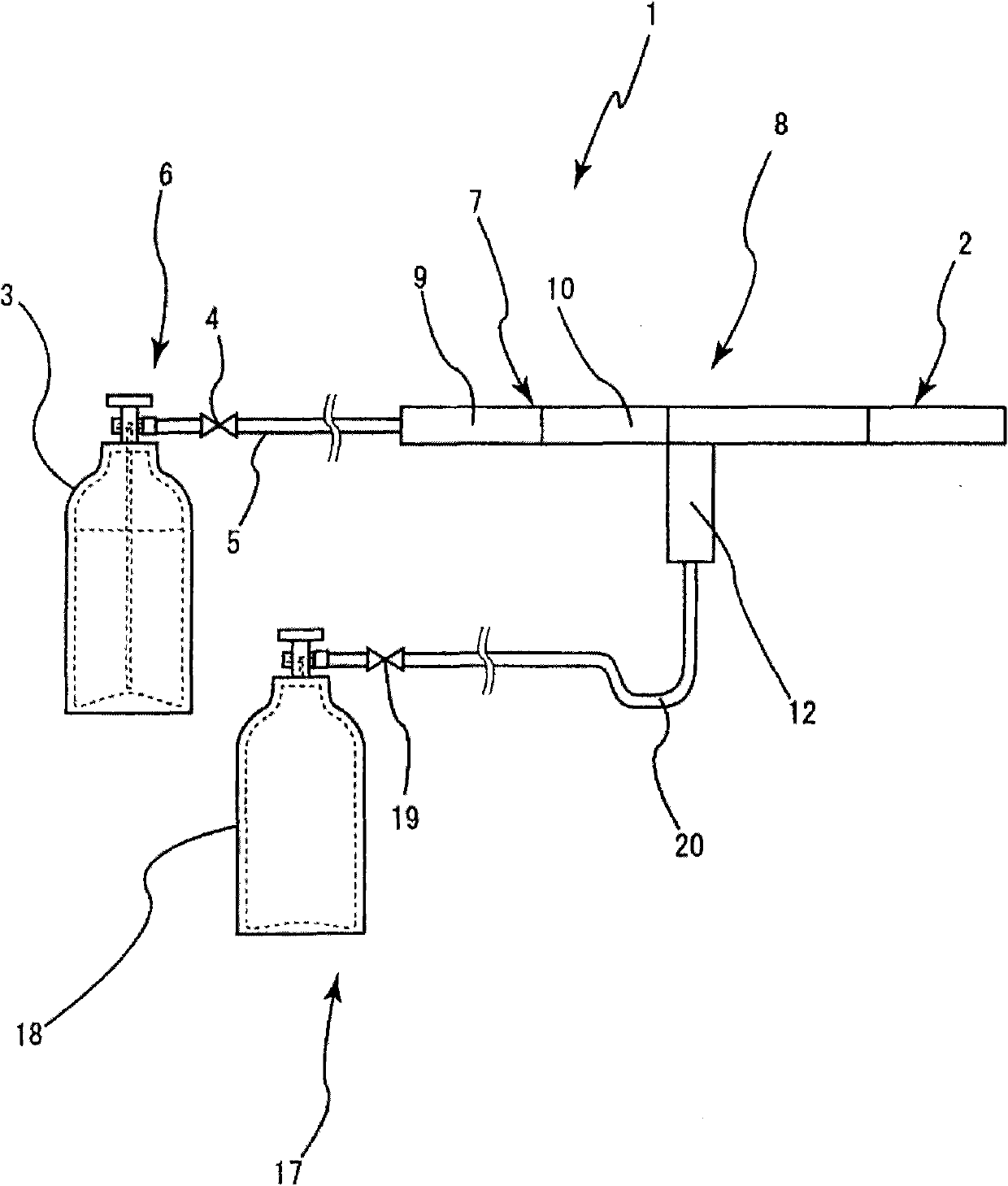

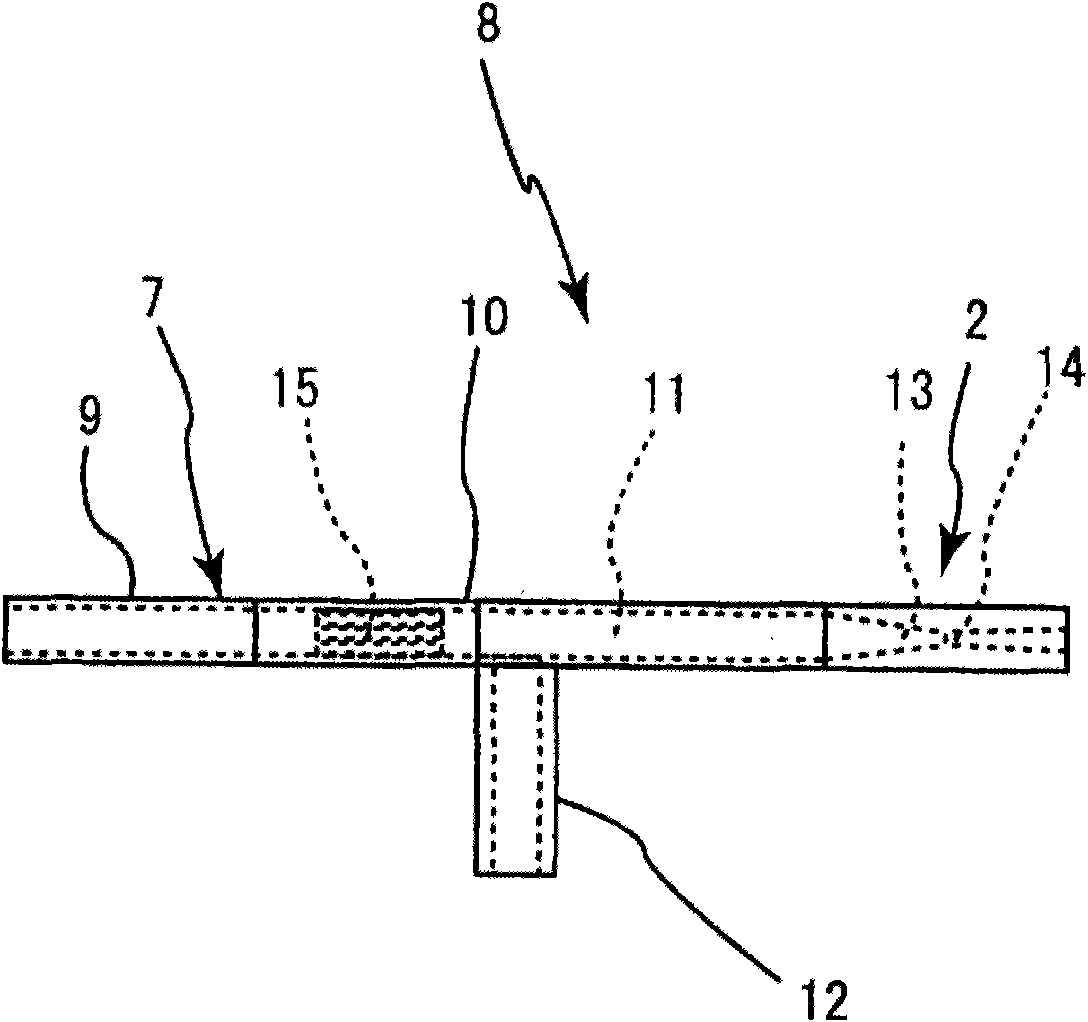

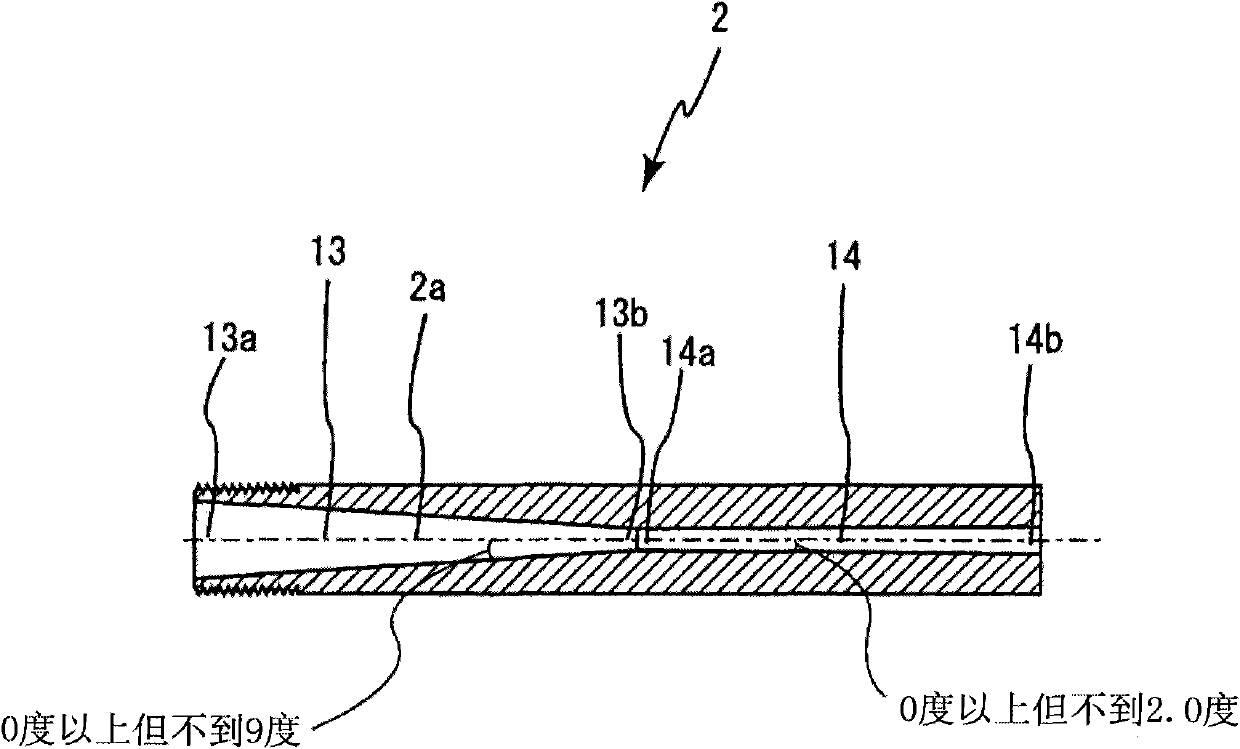

[0058] exist Figure 1 to Figure 6 In the first embodiment of the present invention shown, 1 is the dry ice particle spraying device of the present invention, which can form dry ice particles by carbon dioxide during use, and spray the dry ice particles through the spray nozzle 2, and the dry ice particles spray The device 1 includes a liquid carbon dioxide supply source 6 and an injection device 8, and the liquid carbon dioxide supply source 6 is composed of a liquid carbon dioxide storage bottle 3 filled with liquid carbon dioxide and a liquid carbon dioxide tube 5 with an on-off valve 4, and the liquid carbon dioxide tube 5 is formed from The liquid carbon dioxide storage bottle 3 supplies liquid carbon dioxide, and the injection device 8 has a gas-liquid carbon dioxide supply flow path 7. Supply liquid carbon dioxide.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com