Method for preparing yarn ends for spinning-in by an open-end rotor spinning machine and spinning rotor

A technology of rotor spinning machine and free end, which is applied in the field of yarn end, and can solve the problems of increasing the complexity of the spinning unit and increasing the production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

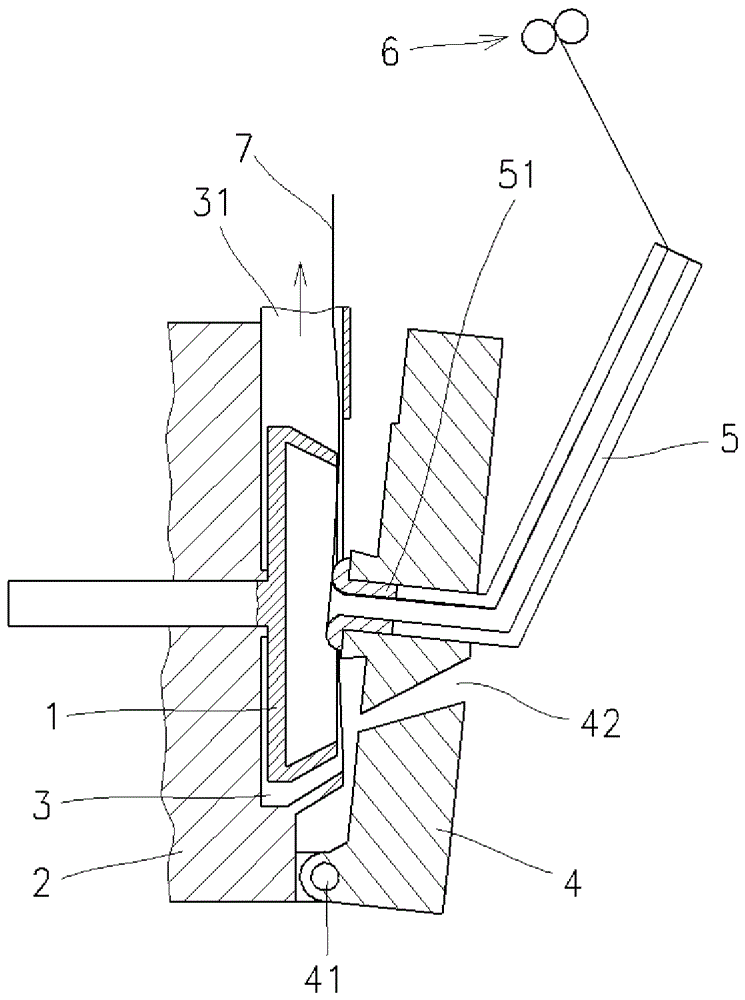

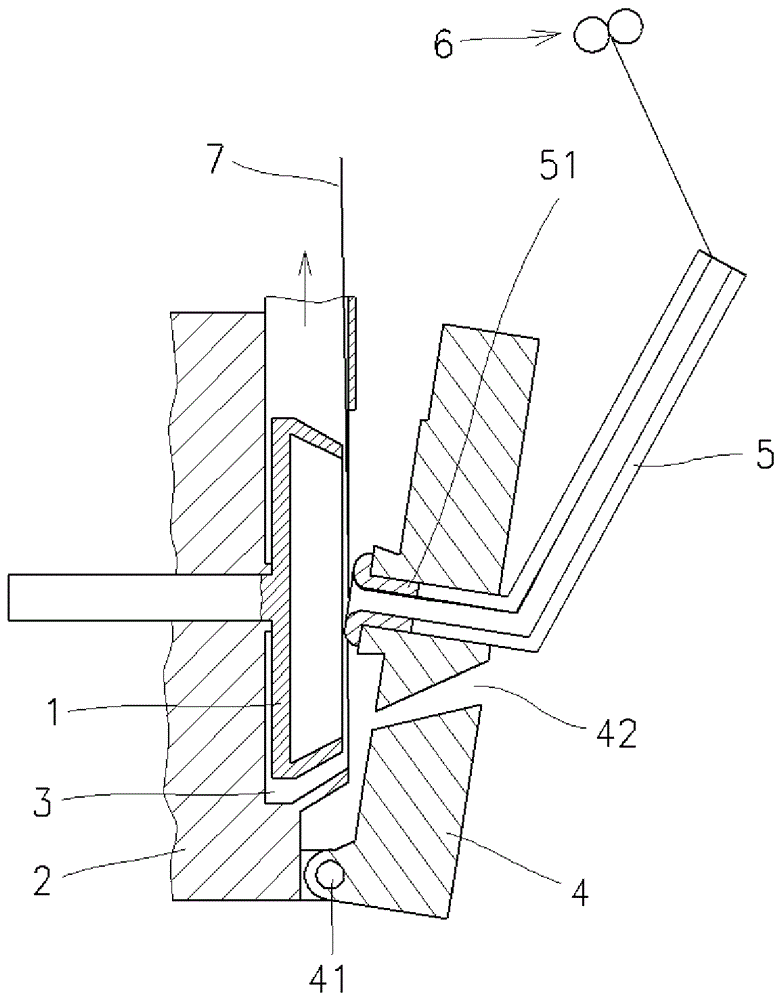

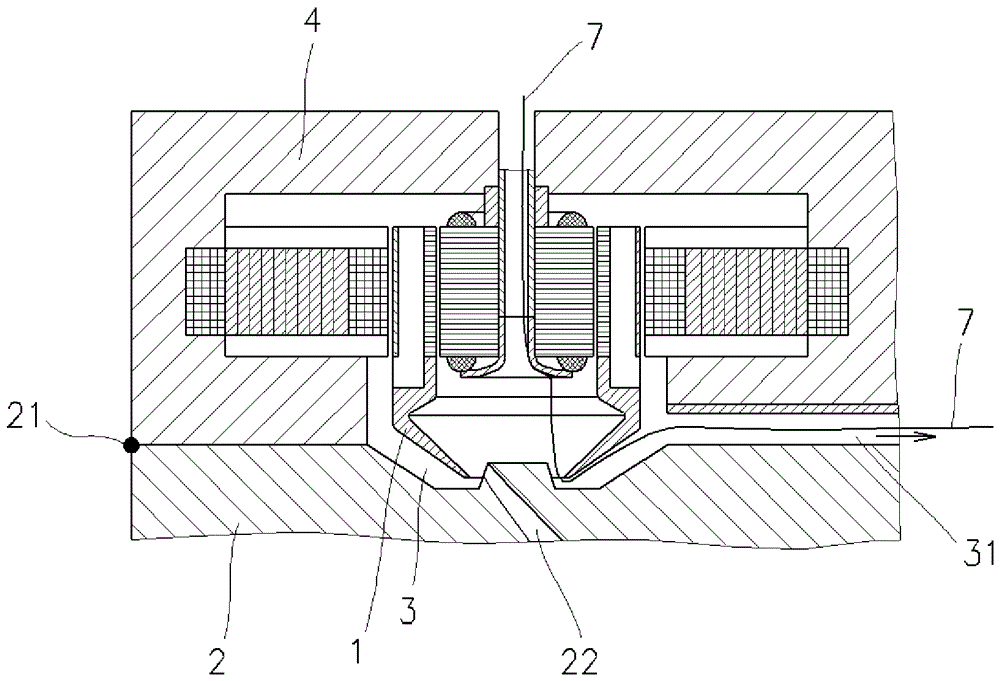

[0020] will be about Figure 1-Figure 3 A single spinning unit of an open-end rotor spinning machine is shown schematically to illustrate the method according to the invention for preparing a yarn end for spinning-in from an open-end rotor spinning machine.

[0021] The spinning unit of an open-end rotor spinning machine comprises a spinning rotor 1 placed in the main body 2 of the spinning unit and coupled to a not shown drive in a not shown rotational manner known to those skilled in the art. The rotor cup 1 comprises a body without ventilation holes and is placed in a vacuum chamber 3 which is connected by a vacuum channel 31 to a not shown vacuum source known to a person skilled in the art. In the application shown, the vacuum chamber 3 is formed in the main body 2 of the spinning unit and is on the outside in its operative position closed by a cover 4 which is removably placed on the main body of the spinning unit, for example by pins 41 2 on. In the cover 4, a channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com