Liquid handling system and a method for analysing a state of a tip

A liquid processing and state technology, applied in analytical materials, liquid/fluid solid measurement, liquid level indicator, etc., can solve the problem of unreliable detection of clogging of the tip, and achieve the effect of reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

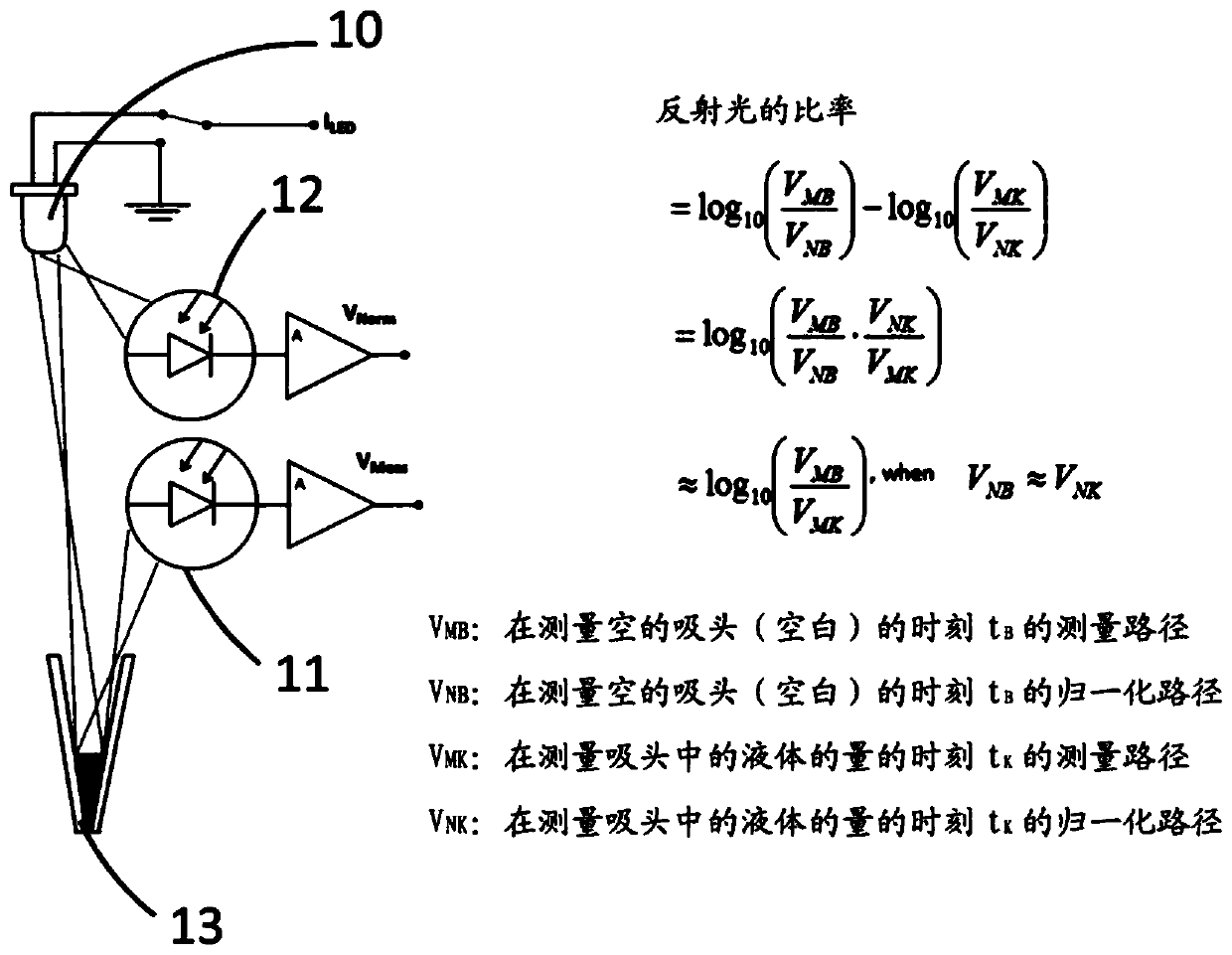

Method used

Image

Examples

Embodiment

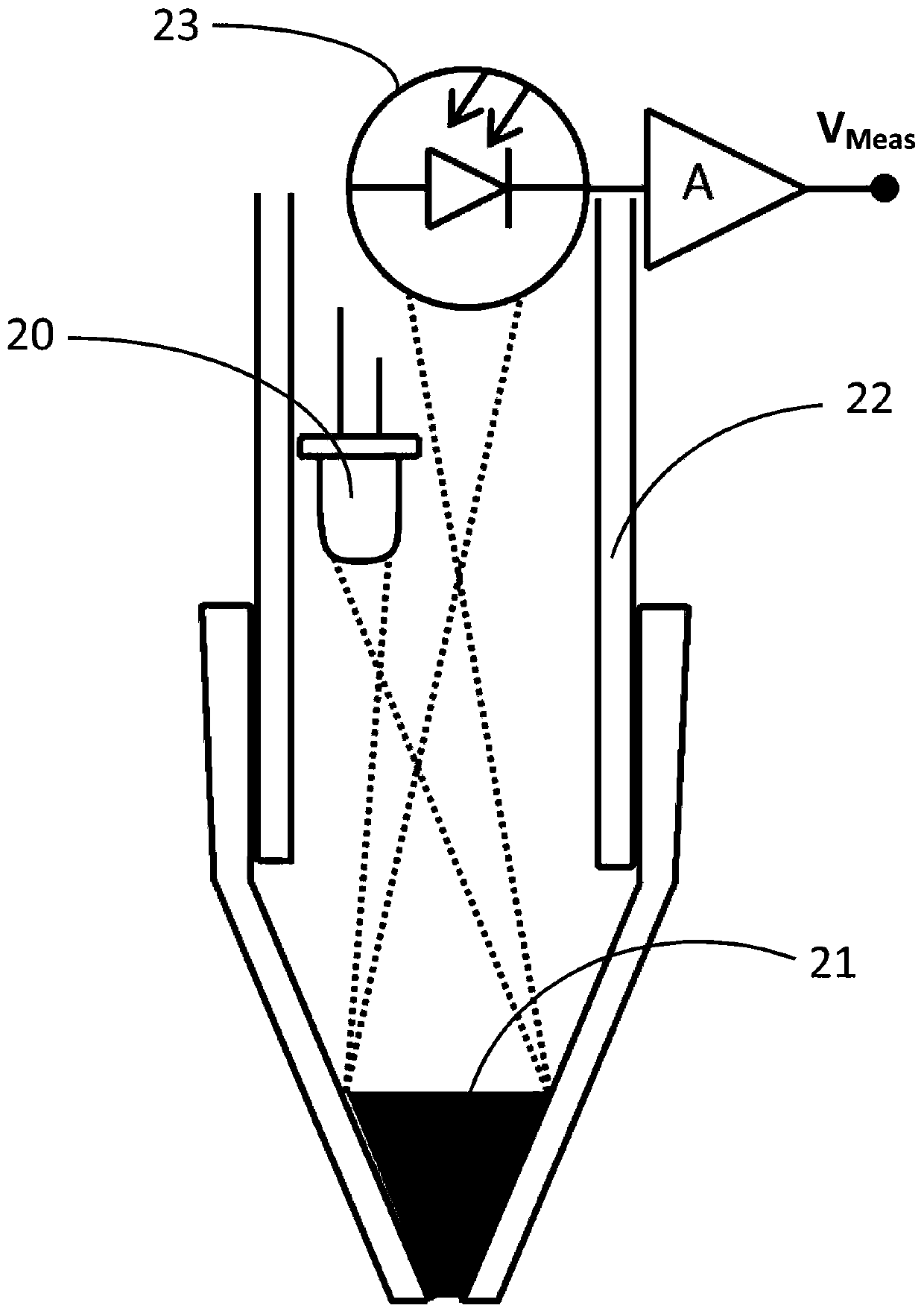

[0130] Figure 19 The measurement system built into a hand-held mechanical pipette (Tacta model from Sartorius) is shown. The system is based on photometry. In this test system, no normalized detector was used. In all other respects, the system uses figure 2 The measurement geometry shown in . During the measurement, 1000-μl tips were used, and the dispensing volume was set at 1000 μl. The detector signal is recorded during liquid aspiration. Digital low-pass filtering is performed by averaging the instantaneous AD converter results obtained by polling from the measurement system. result in Figure 20 Shown in is a graph of measured signal intensity versus liquid volume in the tip. The results show that the system can reliably detect the presence of liquid in the tip and pick up the tip successfully.

[0131] It is to be understood that the disclosed embodiments of the invention are not limited to the specific structures, process steps or materials disclosed herein, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com