Connecting method of printed circuit board

A printed circuit board and connection method technology, which is applied in the structural connection of printed circuits, printed circuits, printed circuits, etc., can solve problems such as difficulty in ensuring the relative accuracy of wires and substrates, difficulty in accuracy, and reduction in the area of mountable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

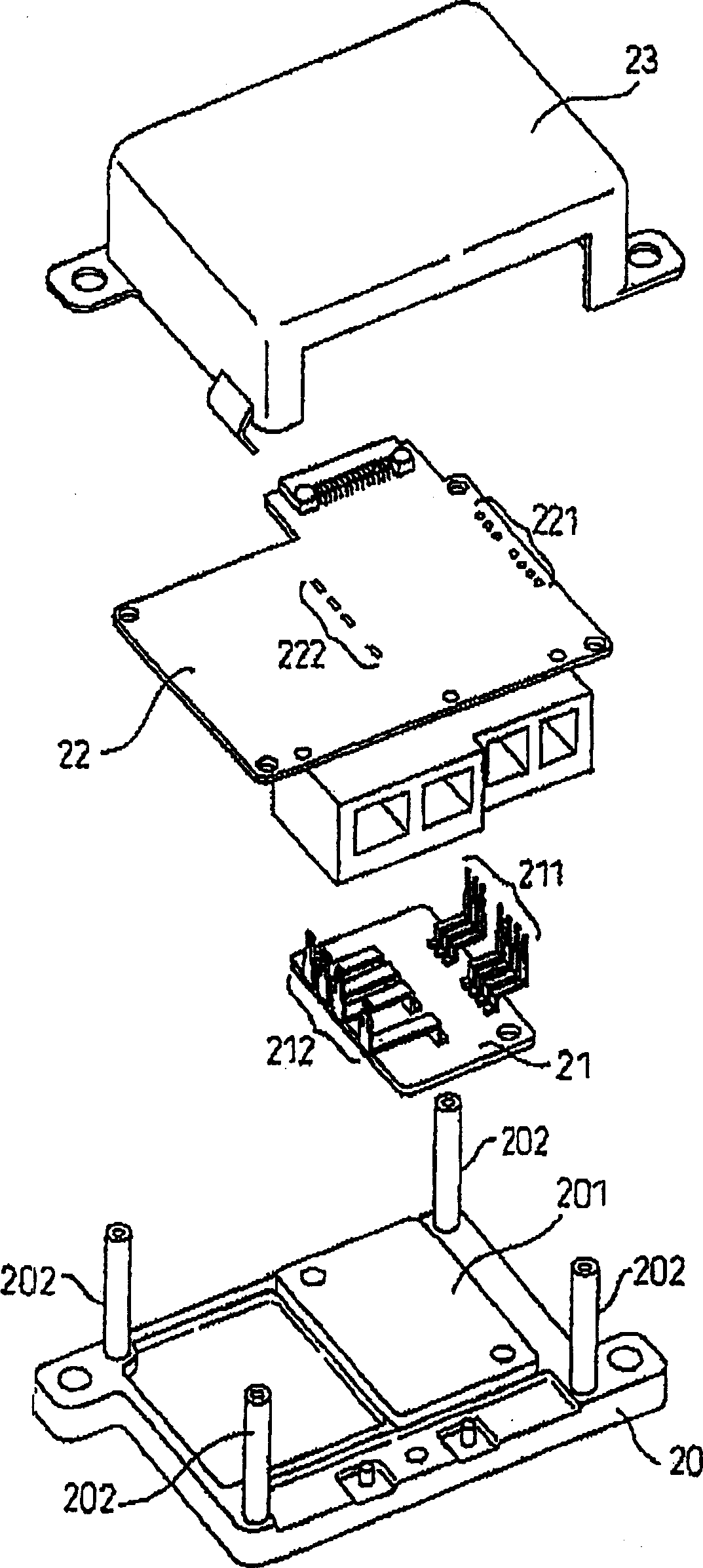

[0035] figure 2 It is a perspective view of the connection structure of the printed circuit board in the present invention, which is composed of a substrate 20 , a power substrate 21 , a control substrate 22 , and a cover 23 .

[0036] The base plate 20 is a cast product of aluminum, and the power board 21 , the control board 22 , and the cover 23 are fixed while radiating heat generated by the fastened power board.

[0037] In the power board 21, for example, the power control element of the IGBT is mounted, and at the same time, the crank-shaped control wire 211 and the power wire 212 are connected by soldering, but the control wire 211 and the power wire 212 are not the resin frame in the conventional structure. stand on the substrate 21 independently.

[0038] The method of attaching the control wire 211 and the power wire 212 to the power board 21 will be described later.

[0039] The power substrate 21 is tightly fixed on the base formed on the substrate by screws thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com