Method and device for detecting polyemid

A technology of alignment film and equipment, which is applied in the direction of measuring devices, optical testing of defects/defects, and material analysis through optical means, which can solve the problems of expensive and cumbersome equipment, and achieve the effect of cheap inspection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

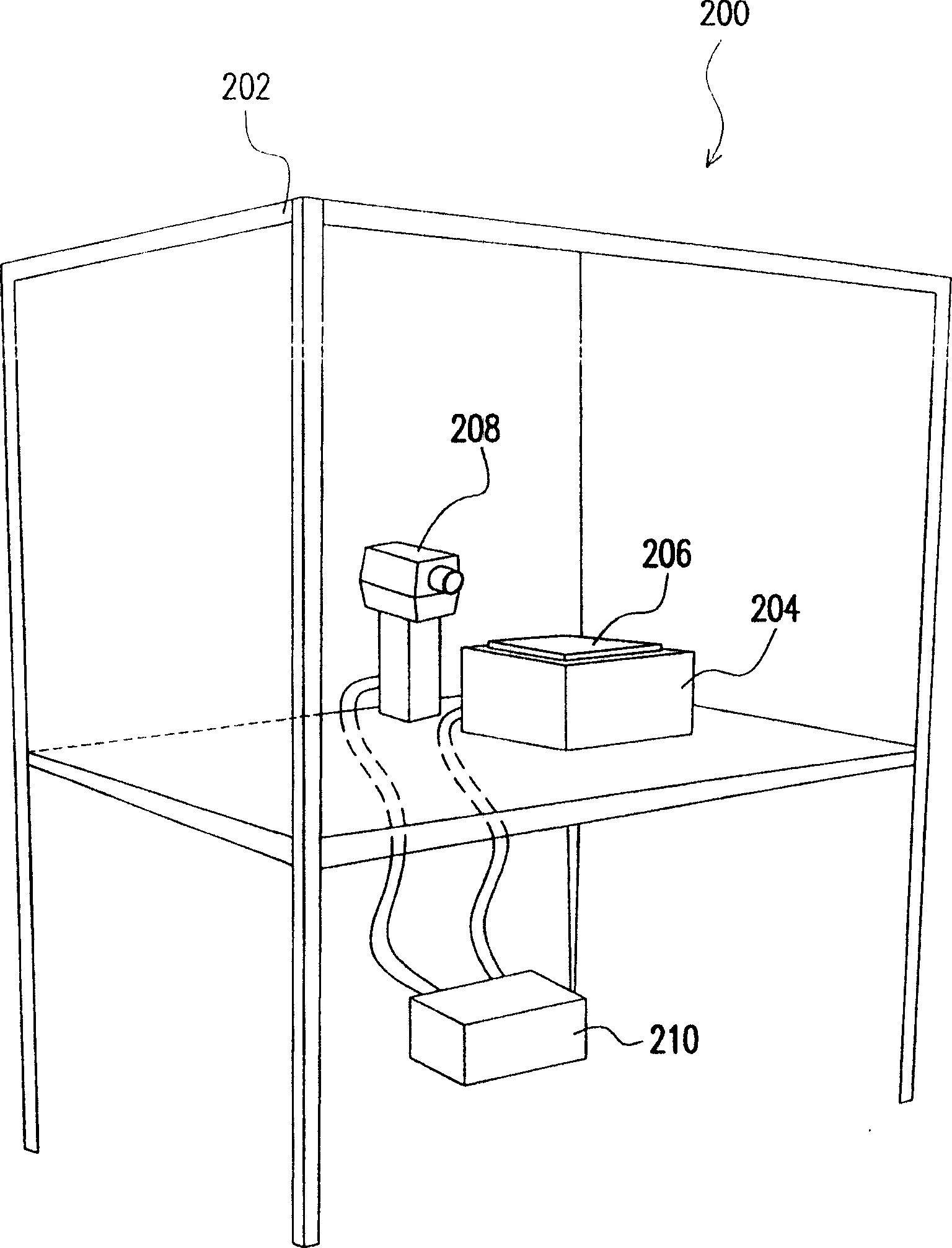

[0025] figure 2 It is a schematic diagram of an apparatus for inspecting an alignment film according to a preferred embodiment of the present invention.

[0026] Please refer to figure 2 , the detection equipment of the alignment film of this embodiment includes a detection chamber 200 , a steam generator 204 and a strong light 208 .

[0027] Wherein, the detection chamber 200 is made of a solid frame, and a black curtain 202 is also covered around the solid frame. Airflow interference is blocked outside.

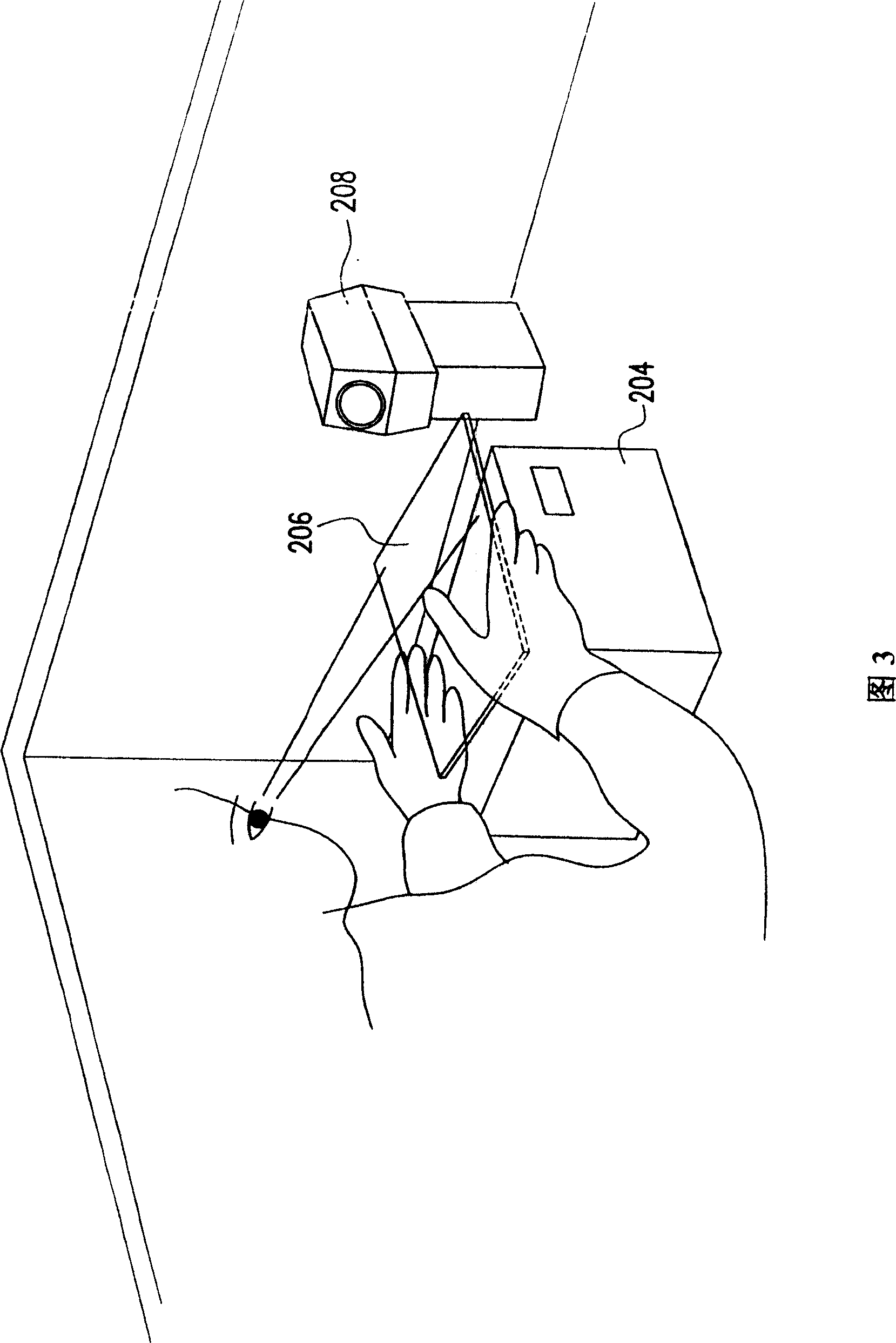

[0028] The steam generator 204 is placed in the detection chamber 200 , and an alignment film test piece 206 to be tested is placed above the steam generator 204 so that the steam generated by the steam generator 204 can atomize the alignment film test piece 206 . Wherein, the alignment film test piece 206 has undergone a grinding process, so many grooves have been formed on the surface of the alignment film test piece 206 . The steam generator 204 is further connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com