Oil filling device of gear case of wind driven generator

A technology for wind turbines and refueling devices, applied in the field of lubrication systems, can solve the problems that flow meters cannot truly reflect oil quality, cannot accurately display, and have hysteresis effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

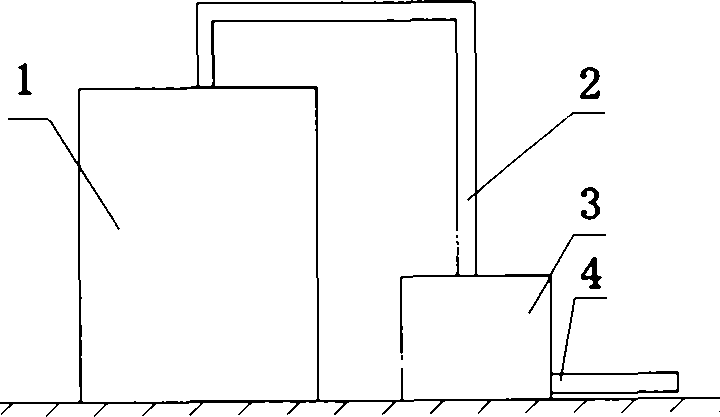

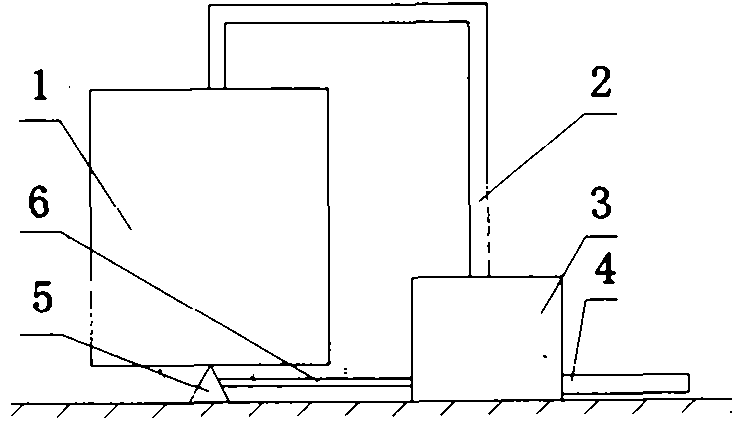

[0018] see figure 2 : the refueling device for the gear box of the wind-driven generator comprises an oil storage tank 1, a hydraulic pump 3, a meter 5, an automatic controller, the oil inlet of the hydraulic pump 3 is connected to the oil storage tank 1 through a pipeline 2, and its outlet passes through Pipe 4 is connected to the gearbox.

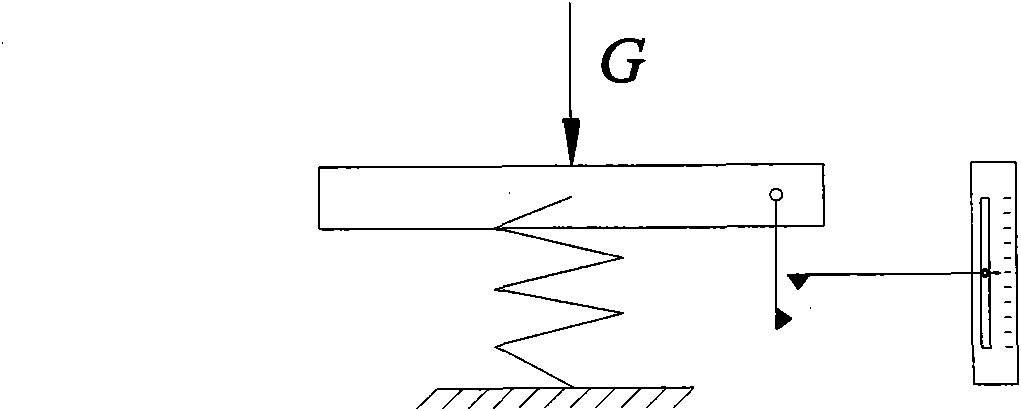

[0019] The present invention is characterized in that: the measuring device 5 adopts a mass meter, which is arranged under the oil storage tank and is used to weigh the oil storage tank.

[0020] From a molecular point of view, mass is a better indicator of the amount of matter than volume. The present invention utilizes the property that the mass and volume of lubricating oil are directly proportional, and uses a mass meter instead of a volume flow meter as a metering method to control the amount of refueling. The most fundamental principle formula that the present invention utilizes is

[0021] V = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com