Organic silicon fluid loss additive and preparation method thereof

A technology of fluid loss reducer and organic silicon, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as oil and gas layer damage, wellbore instability, etc., and achieve improved potential, ideal high temperature resistance, strong Adsorptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

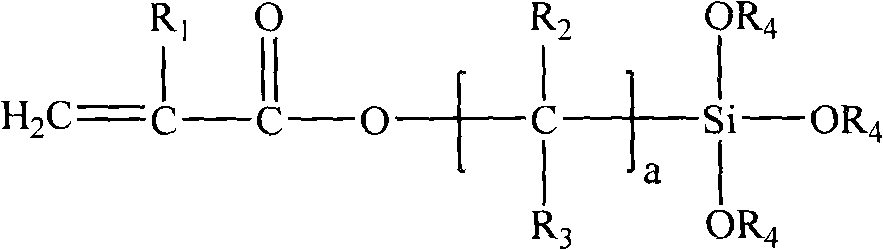

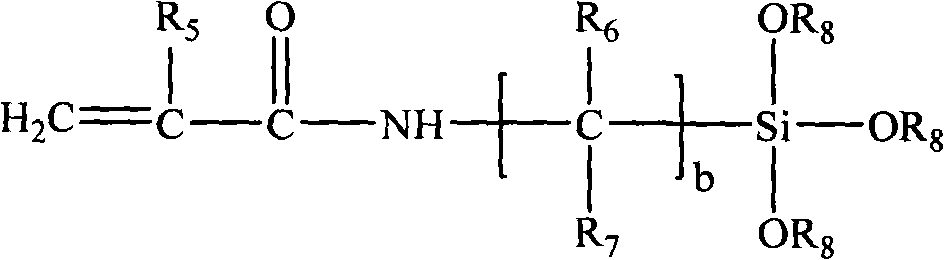

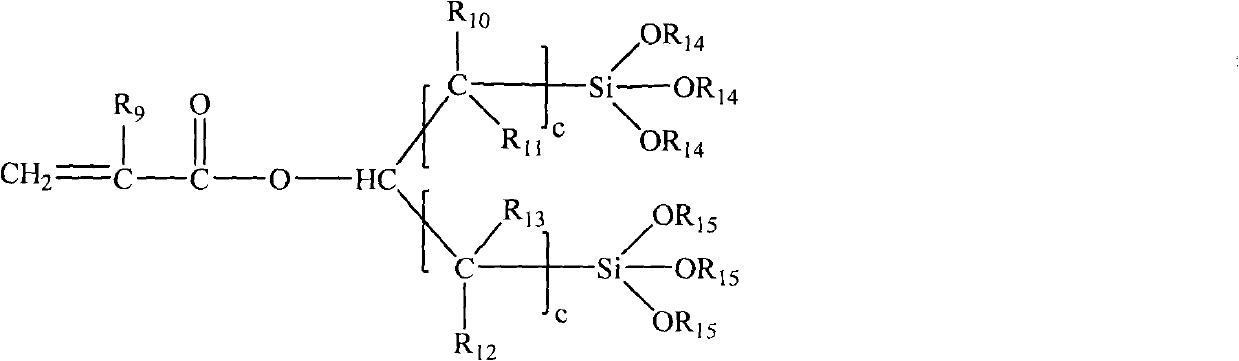

Method used

Image

Examples

preparation example Construction

[0036] This embodiment also provides a preparation method for the above-mentioned polymer-type silicone fluid loss reducer, which includes the following steps in sequence: dissolving a certain amount of alkenyl sulfonic acid in a solvent, neutralizing with alkali to pH=6-8, and then drying The corresponding alkenyl sulfonate can also be used directly without neutralization. While stirring, add alkenyl sulfonic acid (or corresponding alkenyl sulfonate), alkenyl amide and alkenyl alkanone in sequence, heat up to the reaction temperature of 40°C to 130°C, pass N 2 After 30 minutes the alkenylsilane was added. Add an initiator, keep the reaction temperature at 40°C to 130°C, and react for 1 to 12 hours to obtain a jelly which is the silicone fluid loss additive.

[0037] This polymerization reaction formula has four kinds of monomers participating in the free radical polymerization reaction, which follows the general law of free radical polymerization reaction. Free radical poly...

Embodiment 1

[0048] Fix the three-necked flask on a heating device, install a stirrer and a reflux condenser, add 200mL N,N-dimethylformamide, add 10.36g of 2-acrylamido-2-methylpropanesulfonic acid to dissolve it, and stir Add 10.66g of acrylamide and 5.56g of N-vinylpyrrolidone in sequence, raise the temperature to 80°C, pass N 2 After 30 minutes, 1.38 g of γ-(acrylamido)propyltriethoxysilane was added dropwise. Add 0.07 g of benzoyl peroxide, keep the reaction temperature at 80° C., and react for 5 hours to obtain a colorless gum. Continue to react for 10 hours to obtain the organosilicon fluid loss product.

Embodiment 2

[0050] Evaluation of temperature resistance and fluid loss reduction effect

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com