Method for edge sealing barrier films

An edge sealing and edge technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of reducing the area of environmentally sensitive devices and not eliminating them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

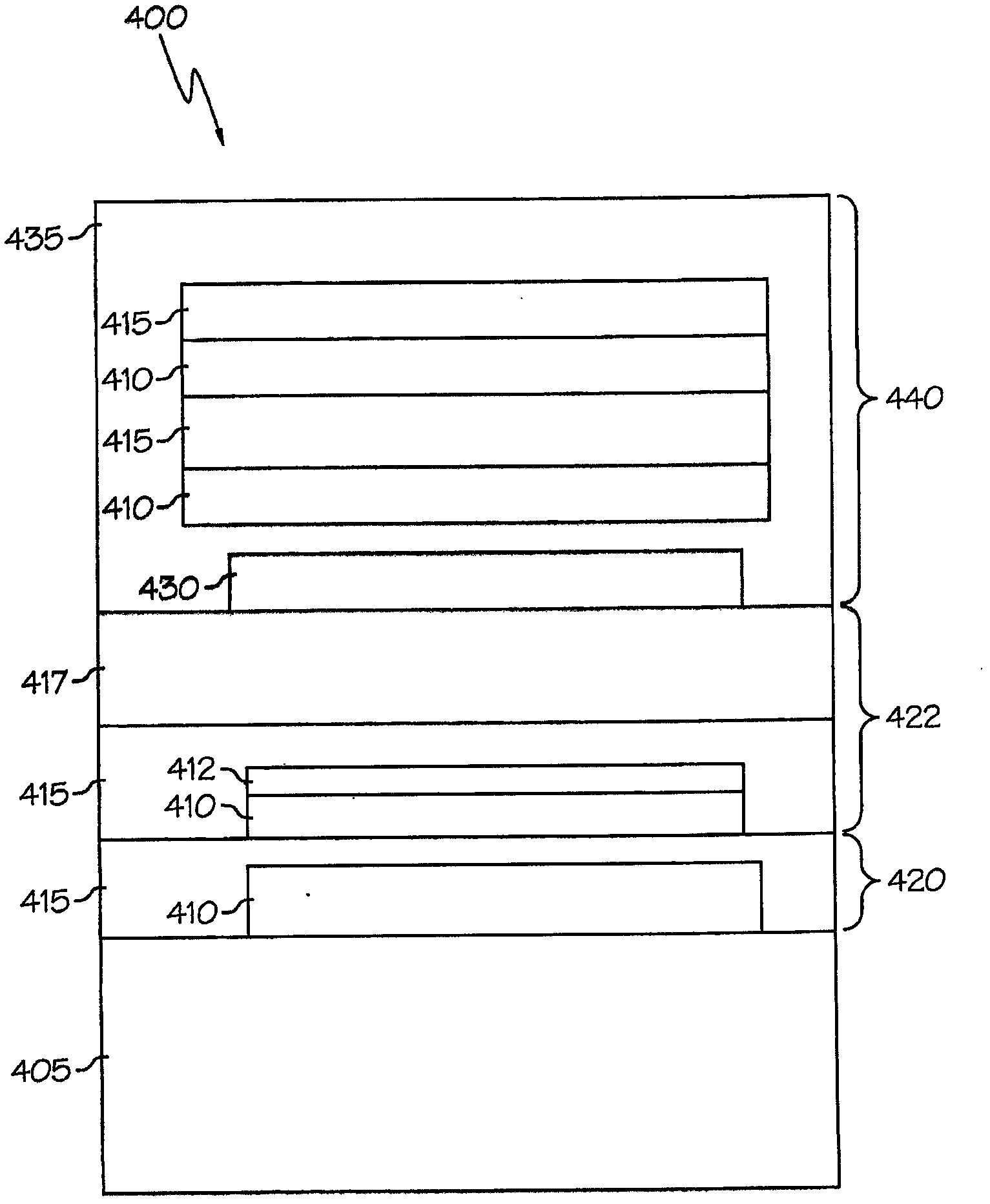

[0021] figure 2 An edge-sealed encapsulated environmentally sensitive device 400 is shown. Substrate 405 may be removed after fabrication of the device, if desired. The environmentally sensitive device 430 is enclosed between an initial barrier stack 422 on one side and an additional barrier stack 440 on the other side. Another initial barrier stack 420 is between the substrate 405 and the initial barrier stack 422 .

[0022] An environmentally sensitive device can be any device that needs to be protected from moisture, gas, or other contaminants. Environmentally sensitive devices include, but are not limited to, organic light-emitting devices, liquid crystal displays, displays utilizing electrophoretic inks, light-emitting diodes, light-emitting polymers, electroluminescent devices, phosphorescent devices, organic optoelectronic devices, inorganic optoelectronic devices, thin-film batteries, Thin film devices, microelectromechanical systems (MEMS), electro-optic polymer mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com