Cutting Fixture

A fixture and channel steel technology, applied in the field of mechanical processing, can solve the problems of affecting product quality, non-vertical cutting surface, time-consuming and labor-intensive problems, and achieve the effect of convenient steel, product quality assurance and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

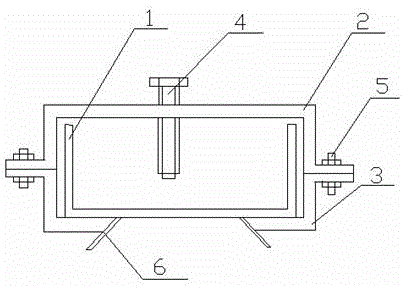

[0015] Such as figure 1 and figure 2 The cutting fixture includes a channel steel 1, the opening of the channel steel 1 is upward, two sets of support feet 6 are welded below the channel steel 1, the plane of the notch of the channel steel 1 is the same as the height of the grinder table, and one end of the channel steel 1 is connected to the grinding wheel. The machine is connected, and a limit device is provided on the channel steel 1 away from the direction of the grinder. The limit device is composed of an upper platen 2 and a lower platen 3 connected by a screw 5. The top surface of the upper platen 2 is provided with a screw hole. Limit bolt 4 is installed inside. When cutting the steel pipe, first choose a clamp that is one size smaller than the diameter of the steel pipe so that the steel pipe cannot roll. After connecting with the grinder, put the steel pipe on the channel steel. horizontal position.

[0016] According to the length of the steel pipe to be cut, mo...

Embodiment 2

[0019] As an improvement of the present invention, the cutting process is the same as in embodiment 1, except that two screw holes in the horizontal direction are provided on the top surface of the upper platen, and bolts are installed in the two screw holes. Among them, the limit bolt 4 is far away from the grinder, and the compression bolt 7 is close to the grinder. Before cutting, loosen the compression bolt 7, and after the steel pipe sticks to the limit bolt 4, tighten the compression bolt 7, and then start cutting. This fixes the steel pipe for better cutting results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com