Automatic press-fitting equipment for elastic pins of hydraulic valves

A hydraulic valve and elastic pin technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as component failure, hole stretching or expansion, poor accuracy, etc., to save labor costs and stabilize the pressing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

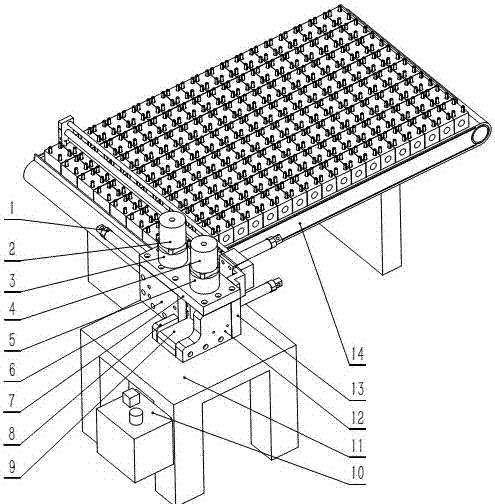

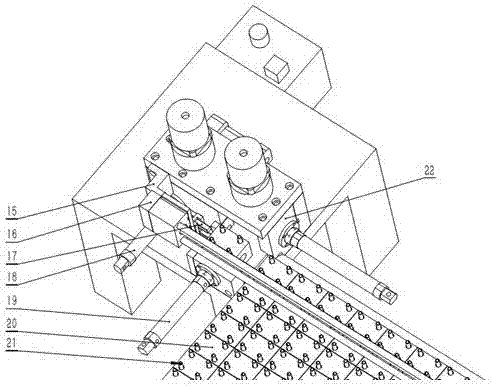

[0014] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an automatic press-fitting equipment for hydraulic valve elastic pins includes a second cylinder 1, a first hydraulic cylinder 2, a first support ring 3, a second hydraulic cylinder 4, a second support ring 5, a front mounting plate 6, an upper Mounting plate 7, right guide plate 8, bottom plate 9, hydraulic pump station 10, base 11, left guide plate 12, rear mounting plate 13, conveyor belt 14, rodless cylinder mounting frame 15, rodless cylinder 16, pneumatic gripper 17, The third cylinder 18, the first cylinder 19, the hydraulic valve body 20, the elastic pin 21, the right mounting plate 22, the first guide rod 23, the first pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com