A positioning method for aircraft skin and panel parts of multiple models

A technology of aircraft skinning and positioning methods, which is applied in the direction of workpiece clamping devices and manufacturing tools, can solve the problems of difficulty in improving the utilization rate of assembly tooling, inability to adapt to the beat of the production line, and inability to achieve positioning, so as to achieve low manufacturing costs and improve utilization Efficiency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

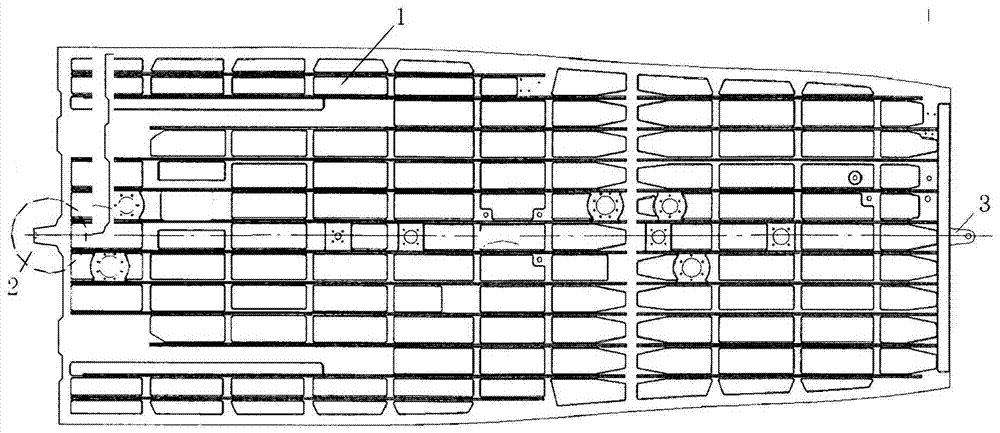

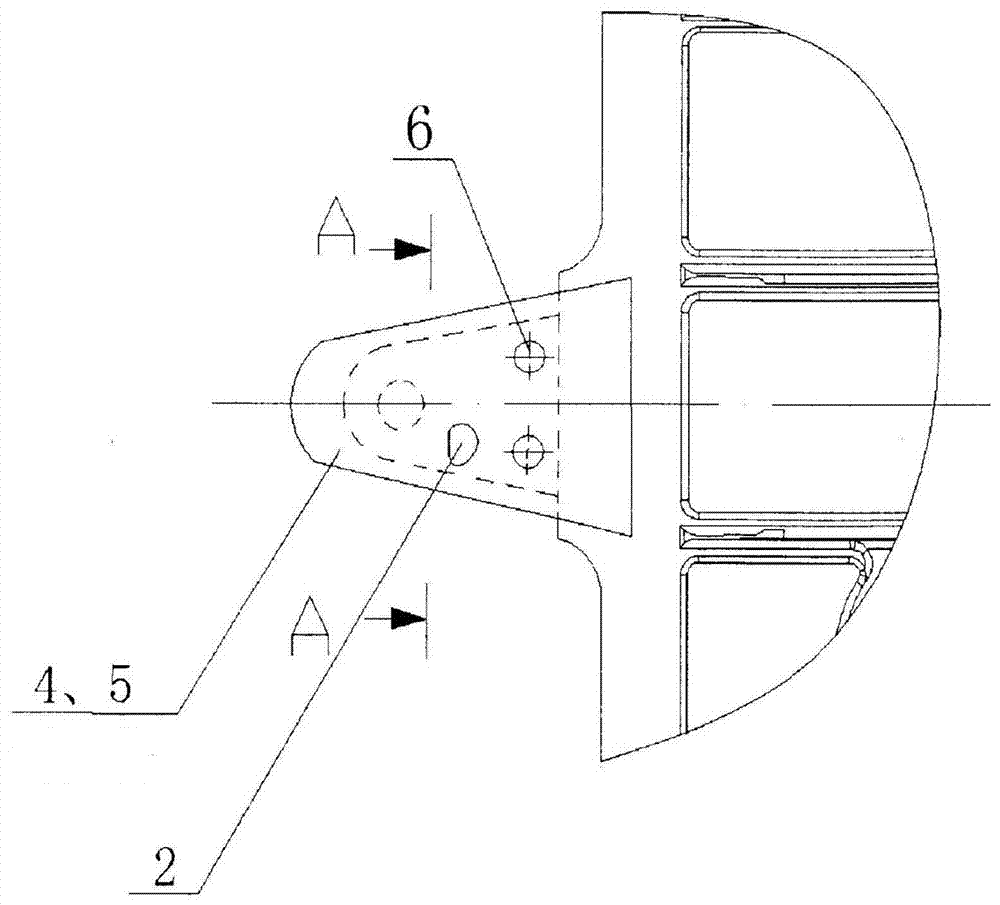

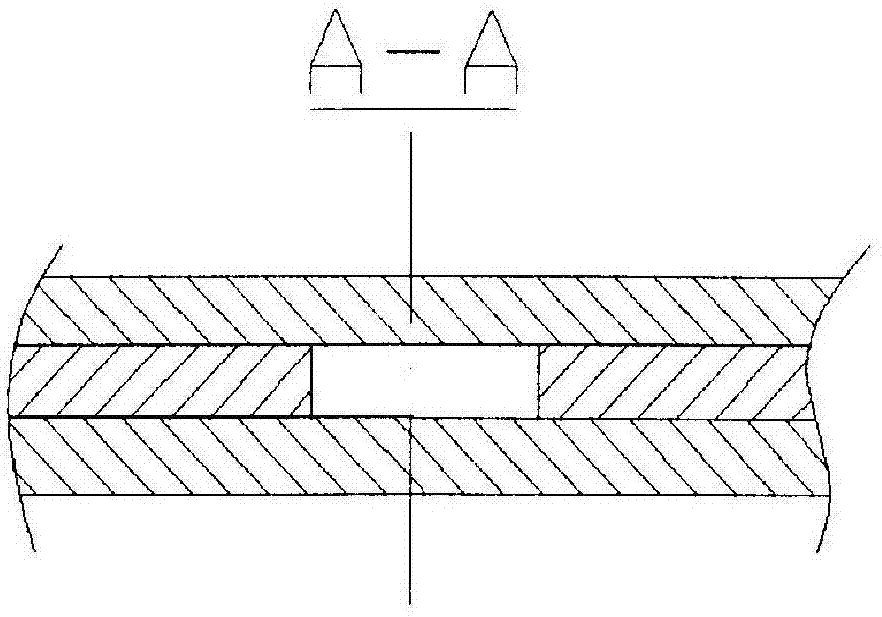

[0018] A positioning method for aircraft skin and panel parts of multiple models, characterized in that the method is based on the original process lugs 2, 3 and the original positioning hole 7, according to the manufacturing data set and the skin and panel 1, the new technology ear piece 4 and the new technology ear piece 5 are respectively installed on both sides of the original technology ear piece 2 and 3, and the new technology ear piece 4 and the new technology ear piece 5 clip the original technology ear piece 2 or 3 Set it up, and then drill positioning holes on the new process lug 4 and new process lug 5 according to the hole shape and hole position of the hole making template, and finally realize the assembly of skin and wall plate parts of multiple models or similar models. The positioning on the tooling, the specific steps are as follows:

[0019] 1) Before the positioning and installation of the skin and wall panels 1, according to the technical conditions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com