A multifunctional installation device for hydraulic nuts of ship stern shafts

A technology of hydraulic nut and installation device, which is applied to metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low work efficiency, inconvenient installation and coordination of the stern shaft end, and labor-intensive, saving labor and convenient adjustment. Quick and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

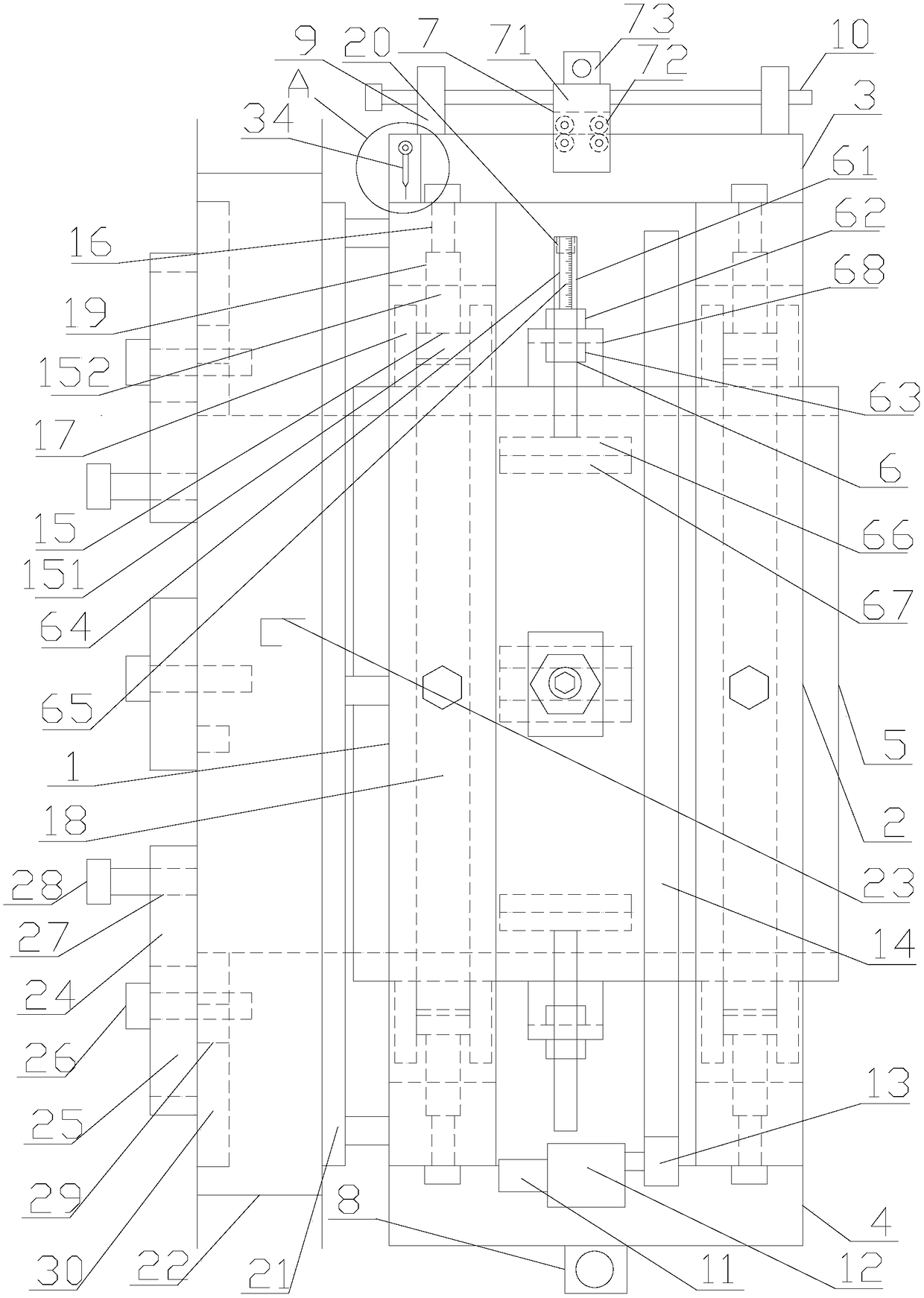

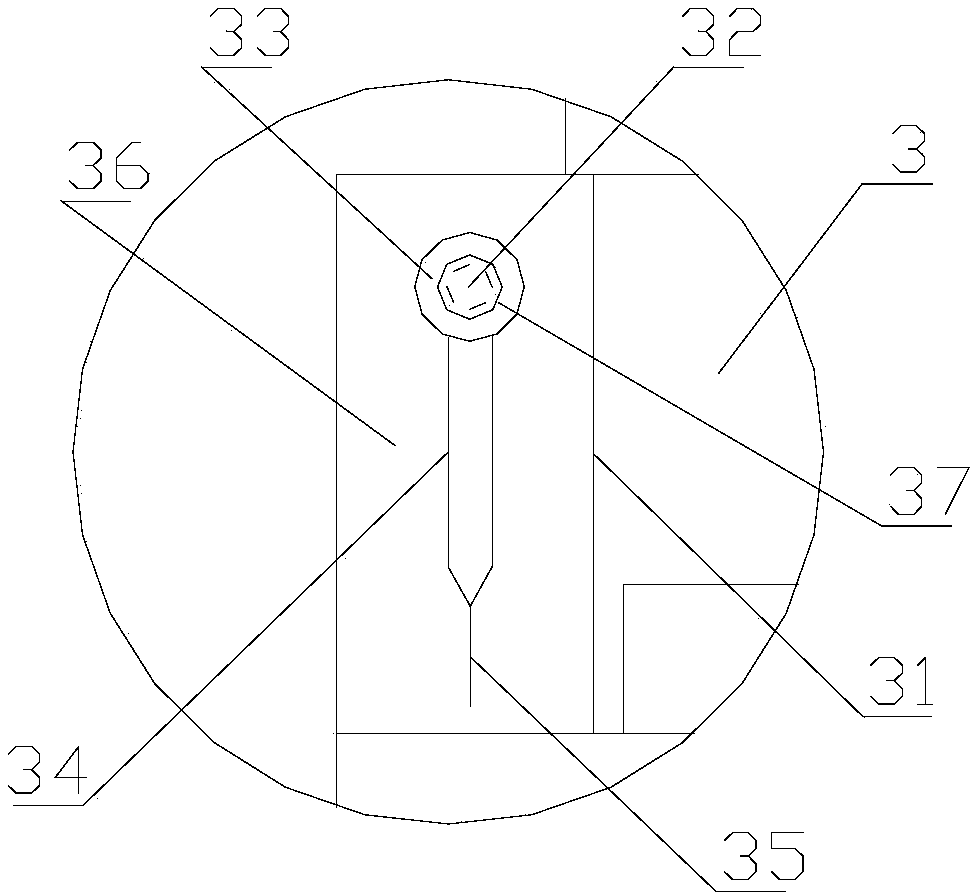

[0018] refer to figure 1 , 2 , the present invention is a multi-functional installation device for a hydraulic nut of a ship stern shaft, comprising a first connecting seat 1, a second connecting seat 2, a first connecting body 3, a second connecting body 4, a rotating sleeve 5, several fixing mechanisms 6, Upper hanging base 7, lower hanging base 8, two mounting bases 9, adjusting screw 10, motor 11, gearbox 12, gear 13, rack 14, bracket 21, turntable 22, fixed hook 23, connecting plate 24, several slotted holes 25. A number of first fixing bolts 26, a number of through holes 27, a number of second fixing bolts 28, a first mounting plate 31, a shaft body 32, a sleeve body 33, a pointer 34 and a reference line 35, the first connecting seat 1 and A rotatable rotating sleeve 5 is installed on the second connecting base 2, and the rotating sleeve 5 is provided with a rack 14 and a circumferentially distributed fixing mechanism 6 between the first connecting base 1 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com