Integrated machine structure of vacuum pump and recovery machine

A vacuum pump and recovery machine technology, applied in the direction of machines/engines, pumps, piston pumps, etc., can solve the problems of inconvenient portability and use, separate configuration, high procurement costs, etc., to reduce processing accuracy and assembly difficulty, easy to use, and universal Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

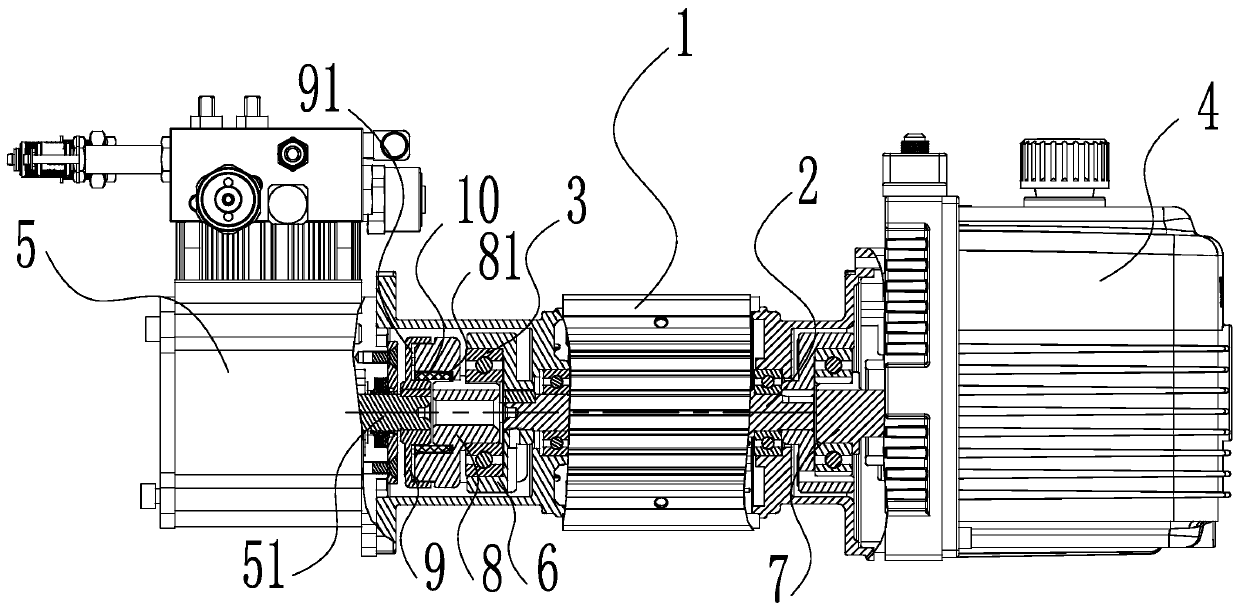

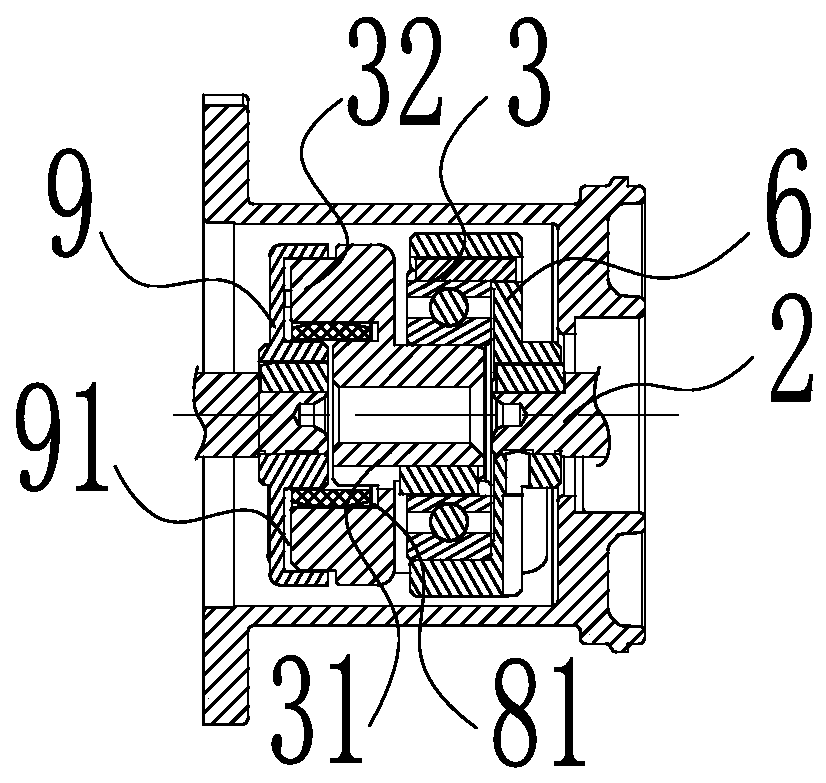

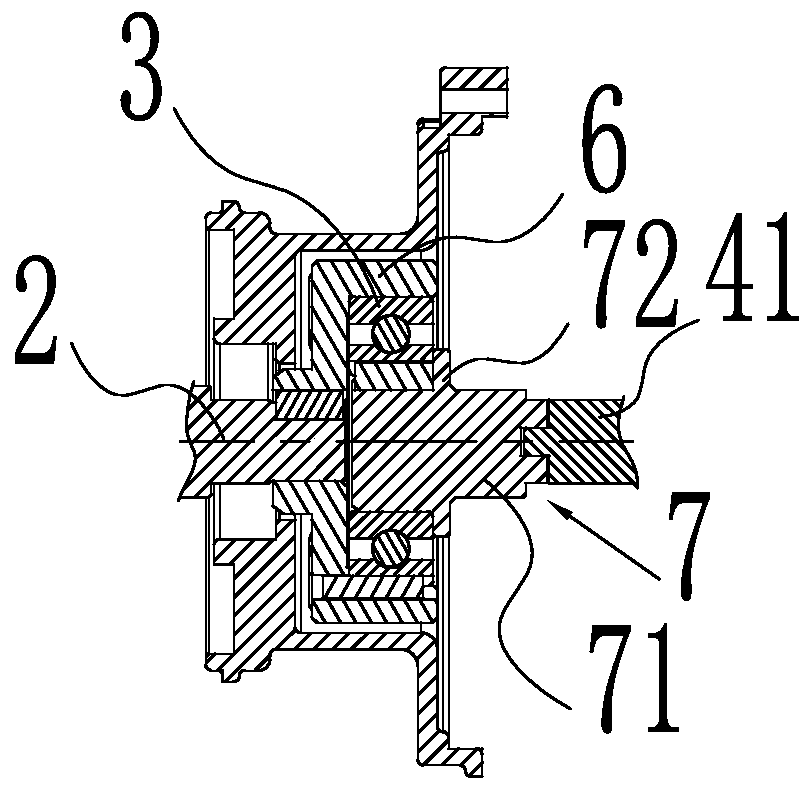

[0019] Such as figure 1 As shown, including the motor 1, the motor 1 can be a brushless motor or an AC motor, the two ends of the output shaft 2 of the motor 1 respectively extend to the outside of the motor 1, and the two left and right ends of the output shaft 2 are respectively keyed to the bearing seat 6 One-way clutch bearings 3 are installed on the corresponding output shafts 2 outside the bearing housing 6, and the one-way clutch bearings 3 are embedded and fixed in the outer ring groove of the bearing housing 6, and the corresponding one-way clutch bearings 3 at the right end The vacuum pump end mandrel 7 is interfitted and inserted into the middle hole, and the outer end of the vacuum pump end mandrel 7 is connected to the rotor shaft 41 of the vacuum pump 4 with a coaxial key, and the corresponding one-way clutch bearing 3 on the left side is interfitted and inserted in the middle hole. Compressor end mandrel 8, compressor end mandrel 8 is coaxially connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com