A connection process between a p21 light bulb base and a bulb body

A P21, lamp cap technology, applied in electrical components and other directions, can solve problems such as the formation of air bubbles in solder joints, achieve the effect of solving defective products and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

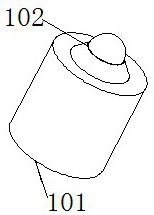

[0024] Such as figure 1 As shown, it is a schematic structural diagram of a P21 lamp holder using this tool for welding mud molding. The overall cylindrical metal shell has an opening 101 at the upper end, which is used to insert the tail of the bulb body into the shell of the lamp holder. The lamp holder shell The lower part of the body shrinks and forms a circular solder opening 102 with a smaller diameter. After the bubble body is fixed in the lamp cap shell, the soldering process at the lower part of the solder opening 102 is performed to form metal conductive solder joints. Among them, when the lamp holder and the bubble body are connected, solder paste is generally used to cement the connection. The solder paste generally contains ethanol and other organic materials that are easy to volatilize in the form of gas during baking and solidification, such as the invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com