A supersaturated high nitrogen stainless steel pressurized slag remelting process

A technology of high nitrogen stainless steel and pressurized slag, applied in the field of metal metallurgy, can solve problems such as poor density, and achieve the effects of good uniformity of structure, excellent mechanical properties and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

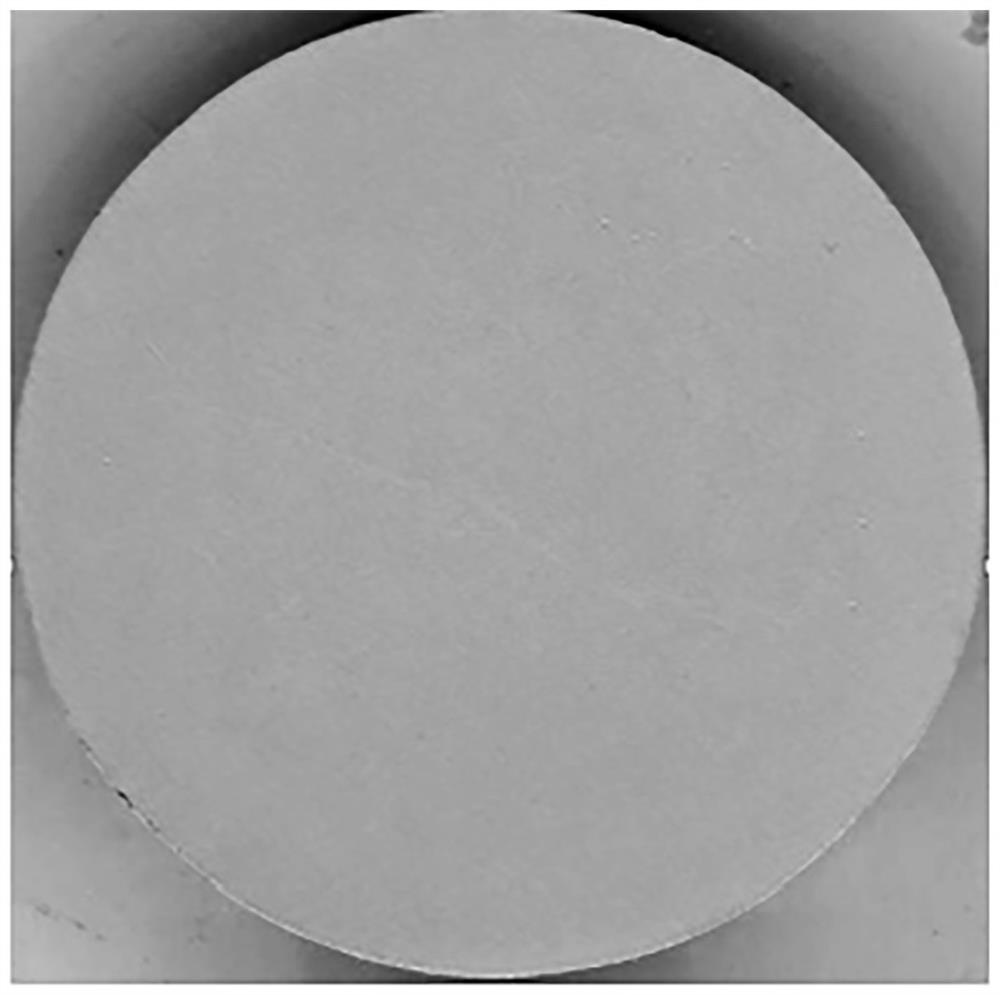

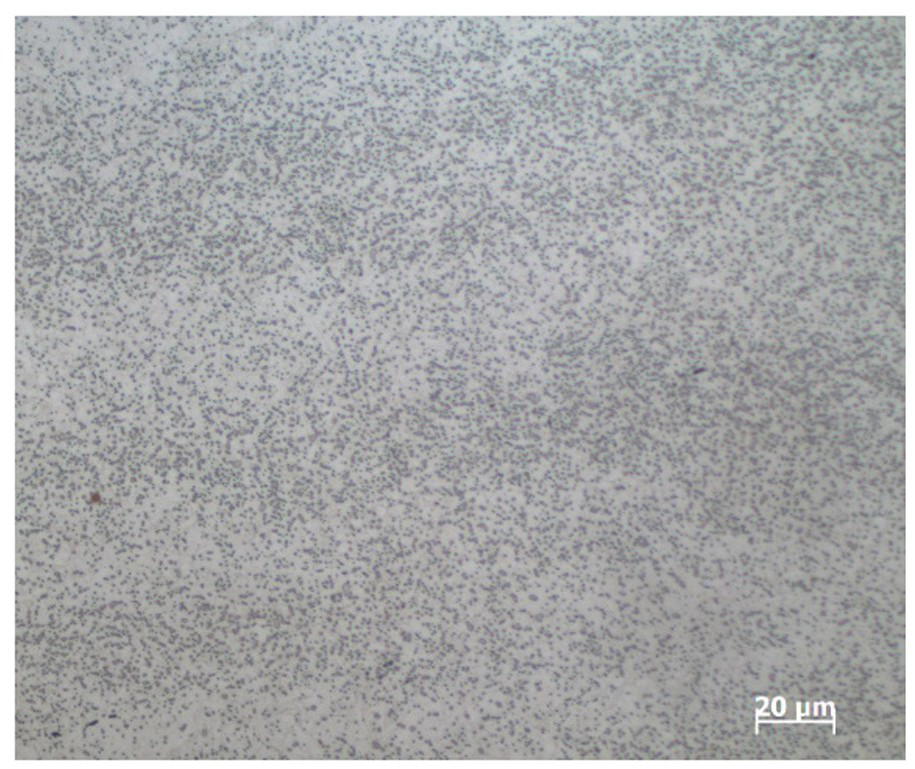

Image

Examples

Embodiment 1

[0046] This embodiment provides a supersaturated high nitrogen stainless steel pressurized slag remelting process, the supersaturated high nitrogen stainless steel is 30Cr15MoN steel, and its chemical composition requirements are (in mass percentage): C 0.28~0.34%, Si 0.30~0.80%, Mn 0.30~0.60%, P≤0.020%, S≤0.010%, Cr14.50~16.00%, Mo 0.95~1.10%, Cu≤0.25%, N0.35~0.44%, Ni≤0.30% , Al≤0.035%, Ti≤0.0030%, the described pressurized electroslag remelting process specifically includes the following steps:

[0047] S1. Preliminary preparations: Thoroughly remove the iron oxide scale on the surface of the electrode rods; make consumable electrodes and dummy plates by welding; lay slag on the dummy plates, electroslag remelting is started by solid slag, and the slag system is pre- Slag, the composition of which, by mass percentage, includes: CaF 2 43.22%, Al 2 O 3 0.32%, CaO 22.05%, SiO 2 21.48%, MgO 12.25%; Assemble the crystallizer, the nominal capacity of the crystallizer used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com