A soft package lithium battery packaging production device

A soft-pack lithium battery and production device technology, applied in the field of soft-pack lithium battery packaging production equipment, can solve the problems of poor cooling effect, reduced production efficiency, long cooling time, etc., to improve cooling effect, improve production efficiency, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

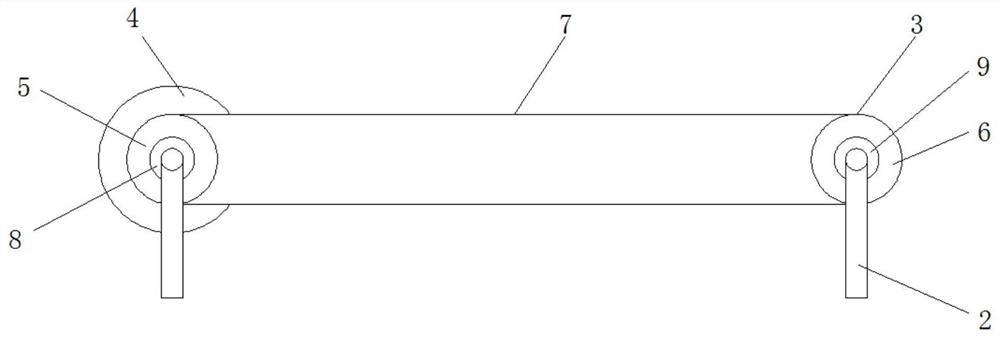

[0026] refer to Figure 1-3 , a soft pack lithium battery packaging production device, comprising a device base 23, a refrigeration box 1 is fixedly installed on the upper surface of the device base 23, a supporting leg 2 is provided on the front side and a rear side of the device base 23, and the upper end of the supporting leg 2 A conveying mechanism 3 is installed, and the conveying mechanism 3 comprises a driving motor 4, a first pulley 5 and a second pulley 6, the outer surfaces of the first pulley 5 and the second pulley 6 are engaged with the same conveying belt 7, and the inner surface of the first pulley 5 The surface is fixedly sleeved with a driving shaft 8, the inner surface of the second pulley 6 is fixedly sleeved with a driven shaft 9, the rear end of the driving shaft 8 is fixedly connected with the output shaft of the driving motor 4, and the vertical walls on both sides of the refrigeration box 1 There is a battery material delivery port 10 at the bottom posi...

Embodiment 2

[0034] refer to Figure 1-4 , a soft pack lithium battery packaging production device, comprising a device base 23, a refrigeration box 1 is fixedly installed on the upper surface of the device base 23, a supporting leg 2 is provided on the front side and a rear side of the device base 23, and the upper end of the supporting leg 2 A conveying mechanism 3 is installed, and the conveying mechanism 3 comprises a driving motor 4, a first pulley 5 and a second pulley 6, the outer surfaces of the first pulley 5 and the second pulley 6 are engaged with the same conveying belt 7, and the inner surface of the first pulley 5 The surface is fixedly sleeved with a driving shaft 8, the inner surface of the second pulley 6 is fixedly sleeved with a driven shaft 9, the rear end of the driving shaft 8 is fixedly connected with the output shaft of the driving motor 4, and the vertical walls on both sides of the refrigeration box 1 There is a battery material delivery port 10 at the bottom posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com