A Method of Equal Error Tool Path Generation for Five-axis Machining of Parametric Curved Surface with Flat Bottom Tool

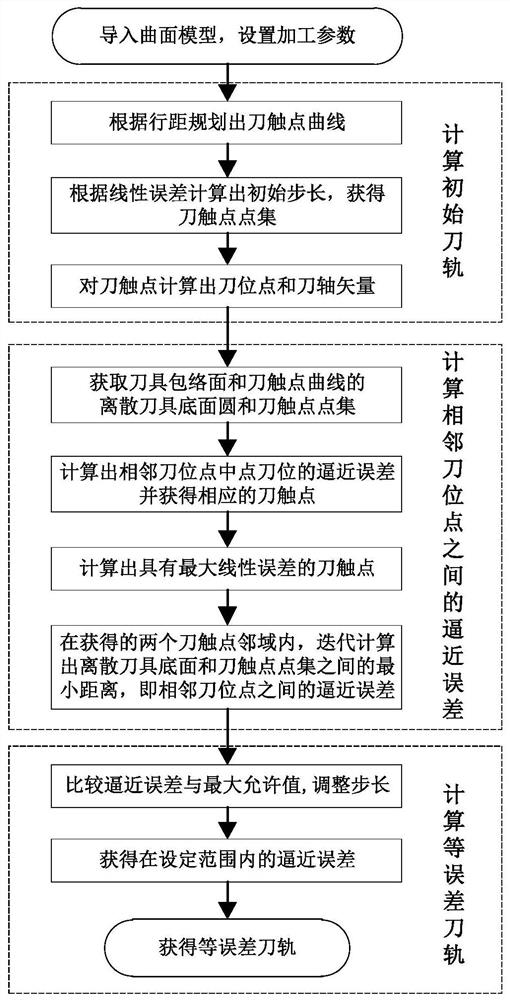

A technology of equal error and flat-bottomed knife, which is applied in the direction of program control, instrument, computer control, etc., can solve the nonlinear error of the linear trajectory of the knife contact, the difficulty of calculating the error knife contact, and the complex geometric characteristics of the approach error of the five-axis flat-bottomed knife and other problems, to achieve the effect of a small number of tool points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

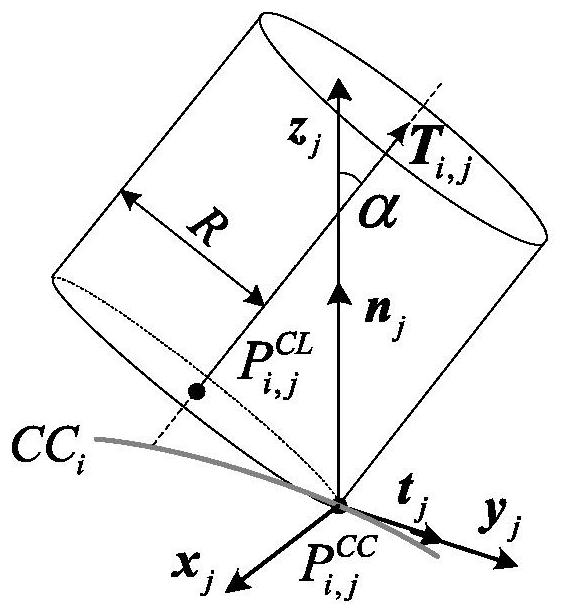

[0113] A typical implementation example of the present invention is as follows:

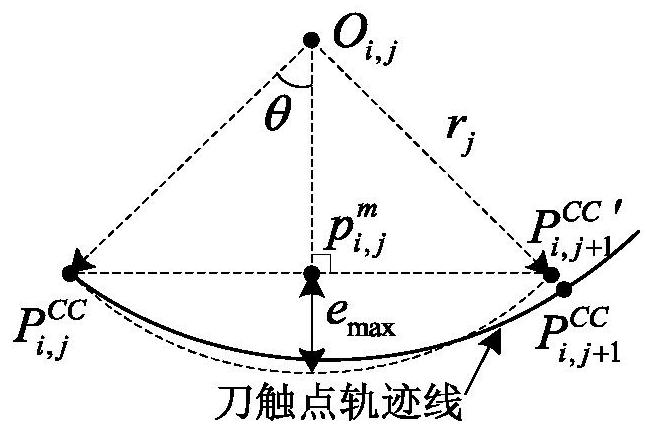

[0114] The selected example is a typical blade surface, such as Figure 9 As shown in (a), the tool chooses a flat-bottomed tool with a radius of 6mm, the total number of tool paths is 221, and the maximum allowable approach error e max is 0.003mm, the lower limit 0.0027mm (0.9e max ), the forward tilt angle is 15°, the position coefficient increment Δk is 0.1, and the parameter increment adjustment coefficient k e is 0.8.

[0115] Figure 9 (b) is the equal-error tool path generated by the method proposed by the present invention. As a comparison, the equal parameter method and the equal step method were used to generate the tool path, and the parameter and step increments were 0.002 and 0.3 mm, respectively. Figure 9 (c) and (d) are the generated tool paths with equal parameters and equal step length. Since the total number of tool tracks is large, 8 tool tracks are selected to compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com