Enameled wire winding structure

A technology of enameled wire and take-up reel, applied in transportation and packaging, electrical components, transportation of filamentous materials, etc., can solve the problems affecting the continuous production of electromagnetic wires, reduce production efficiency, increase production costs, etc., to avoid standby maintenance time. , Improve production efficiency and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

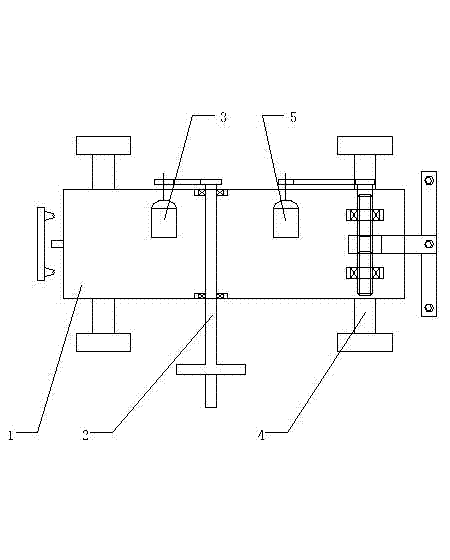

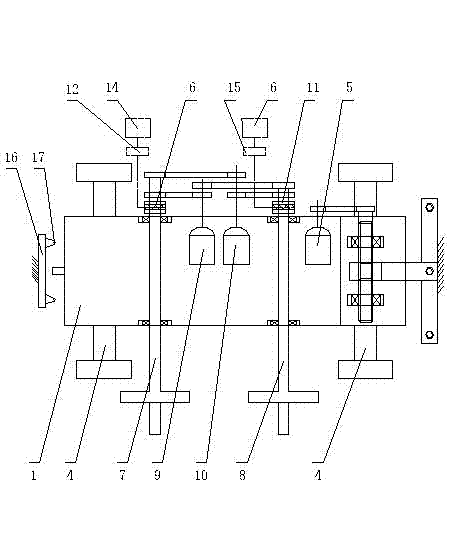

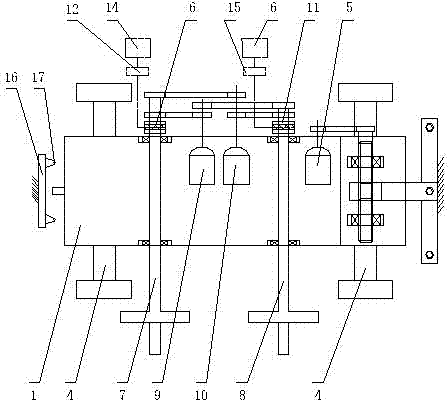

[0009] See figure 2 , the enameled wire take-up structure of the present invention, which includes a take-up workbench 1, the two ends of the take-up workbench 1 are installed on the sliding guide rail 4, and the slide guide rail 4 is connected with a cable motor 5 through a gear and a synchronous belt transmission, and the take-up workbench Take-up shaft 7,8 is installed on 1, and take-up shaft 7,8 connects take-up motor 9,10 by gear and synchronous belt transmission respectively, and take-up shaft 7,8 is installed on the take-up workbench 1 in parallel. Electromagnetic clutch 6,11 is respectively installed on the take-up shaft 7,8; Electromagnetic clutch 6,11 connects DC power supply 14,15 through independent switch 12,13;

[0010] When working, the wire is transmitted to the end of the take-up shaft through the traction motor, and the take-up reel is installed on the end of the take-up shaft. The wire arranging motor 5 drives the sliding guide rail 4 to rotate, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com