Semiconductor layer, method of manufacturing the same, laser diode, and method of manufacturing the same

一种制造方法、半导体的技术,应用在半导体激光器、半导体/固态器件制造、激光器等方向,能够解决激光器可靠性受损、晶体缺陷增加等问题,达到抑制杂质失去活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. Descriptions are given in the following order:

[0026] 1. Structure

[0027] 2. Manufacturing method

[0028] 3. Function and effect

[0029] 1. Structure

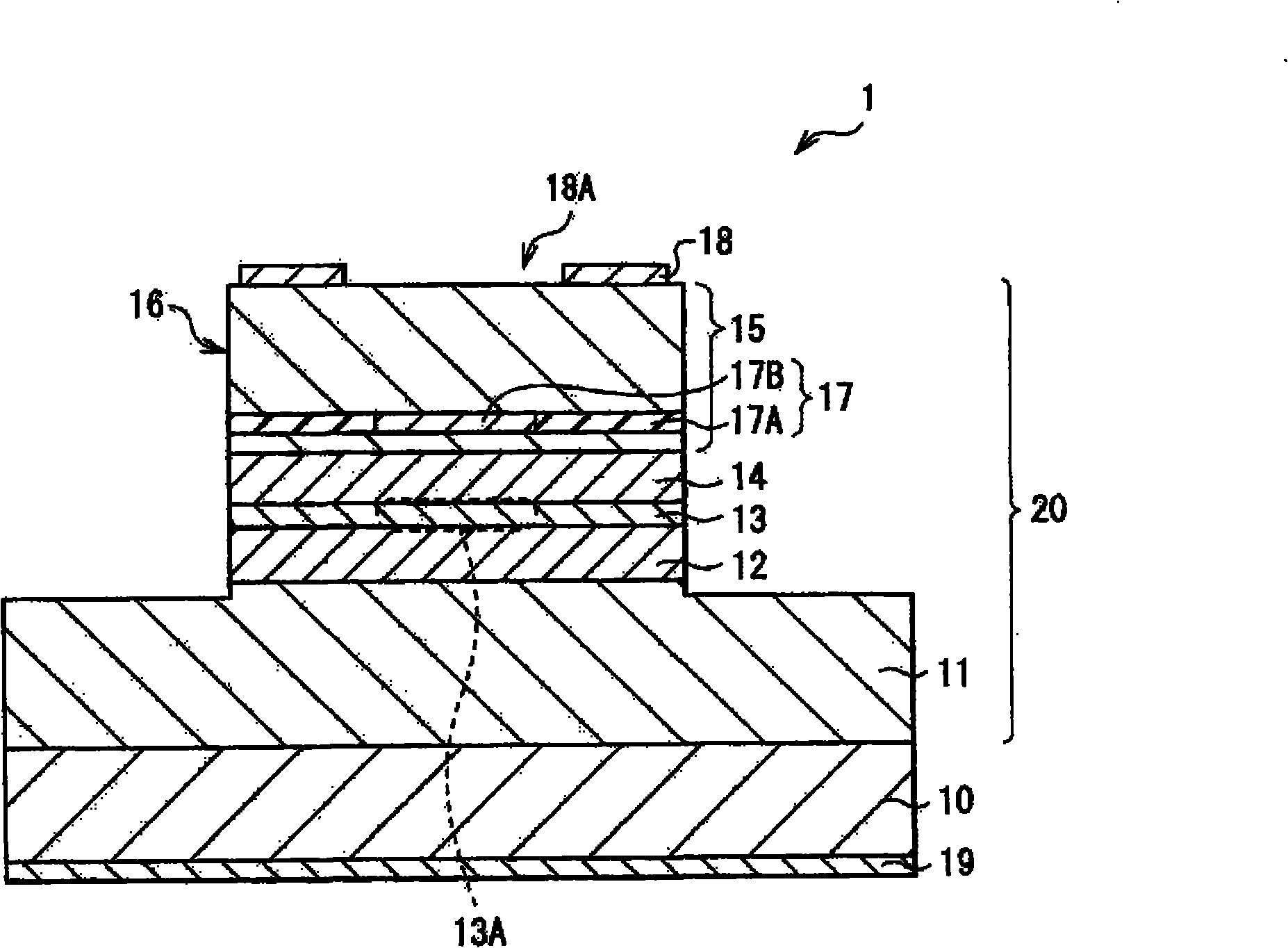

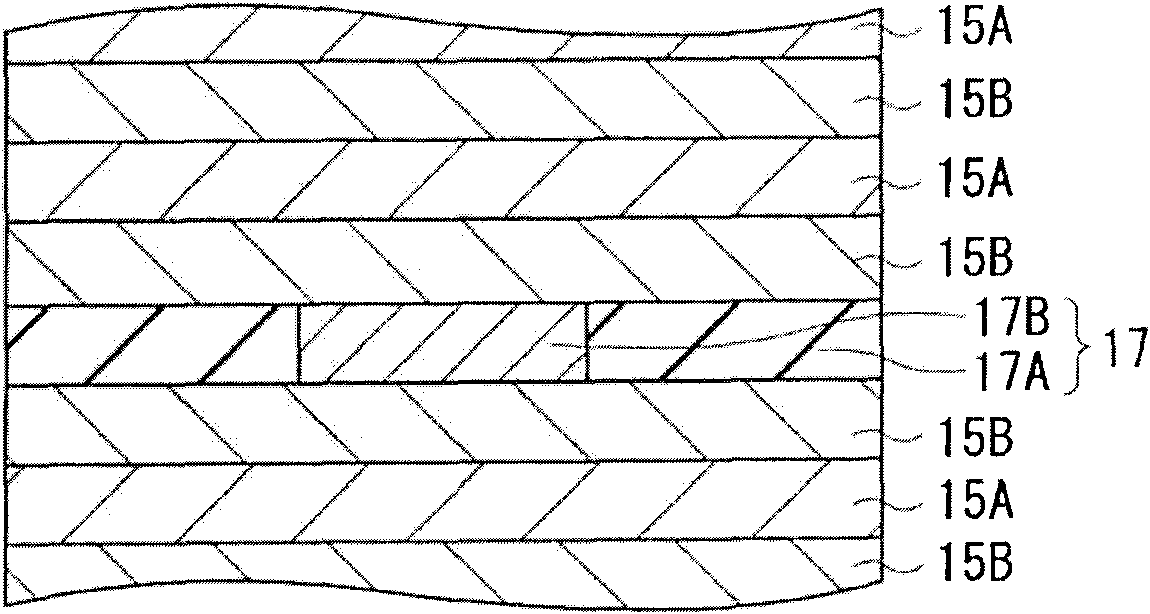

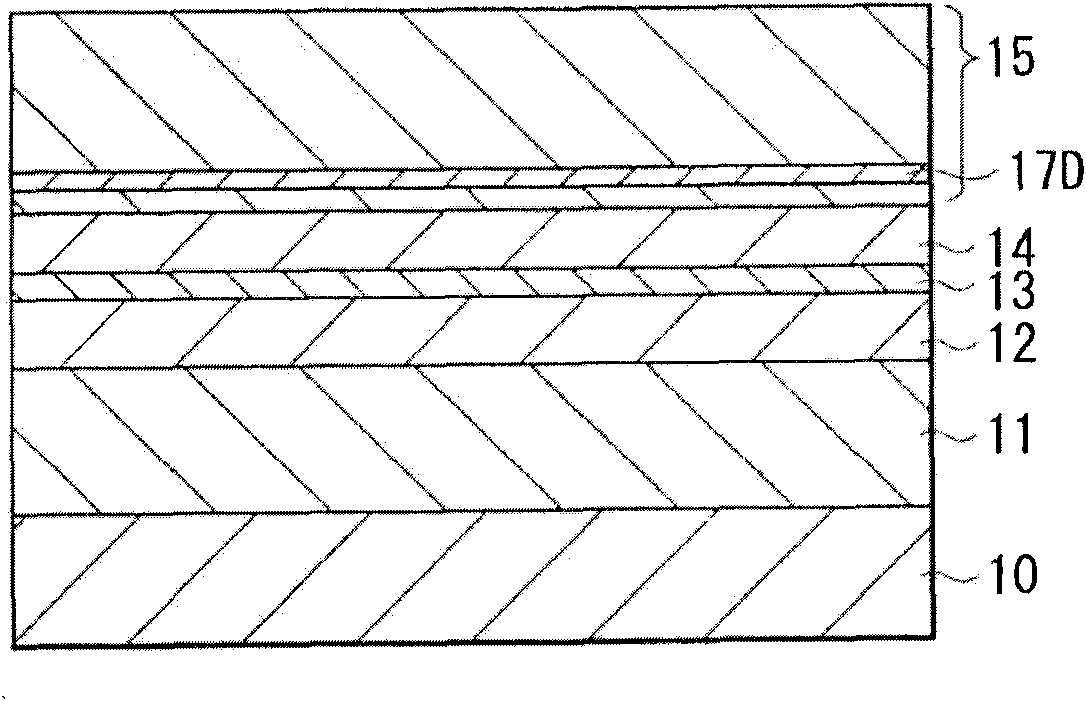

[0030] figure 1 A cross-sectional configuration of a VCSEL according to an embodiment of the present invention is illustrated. figure 1 is a schematic diagram, so the size and shape of the laser 1 are different from the actual size and shape. Laser diode 1 includes stacked structure 20 in which lower DBR layer 11 , lower spacer layer 12 , active layer 13 , upper spacer layer 14 , and upper DBR layer 15 are sequentially stacked on one surface side of substrate 10 . The laminated structure 20 corresponds to a specific example of the "laminated structure" of the present invention. The upper part of the stacked structure 20 , specifically, part of the lower DBR layer 11 , lower spacer layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com