A kind of low-viscosity heat-conducting epoxy pouring glue and preparation method thereof

An epoxy casting and low viscosity technology, which is applied in the field of insulating materials, can solve the problems of high viscosity, low impact performance, and difficulty in pouring, etc., and achieve the effects of improving thermal conductivity, improving impact performance, and preventing settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

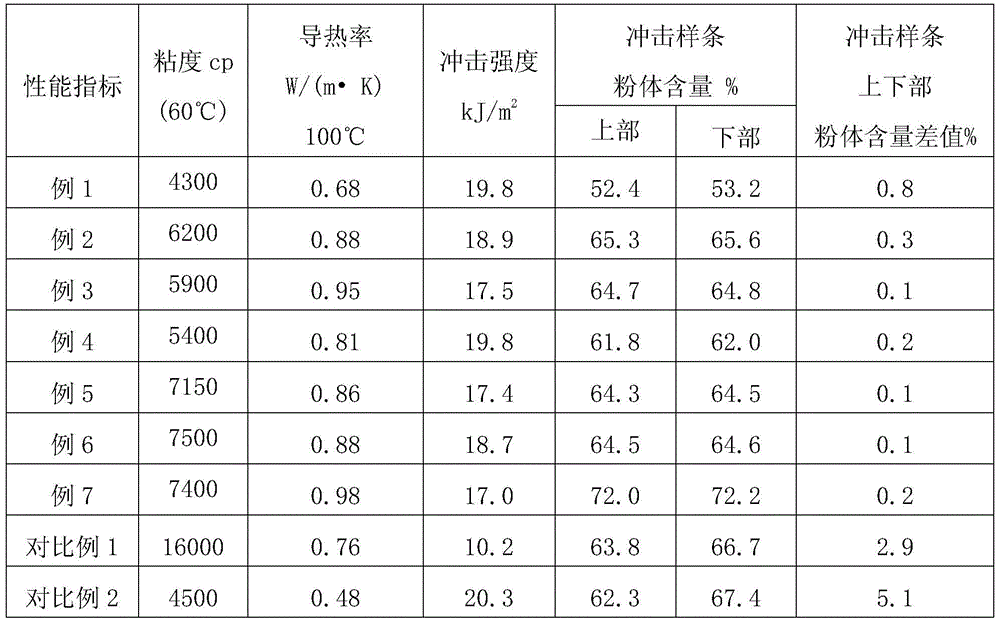

Examples

Embodiment 1

[0028] The components of the thermally conductive epoxy casting glue in this example are as follows:

[0029] A component, bisphenol A type epoxy resin 40g, novolac type epoxy resin 25g, alicyclic epoxy resin 35g;

[0030] Component B, 80g of methyl hexahydrophthalic anhydride;

[0031] Component C, 40g of spherical alumina powder with a particle diameter of 10 microns, and 160g of non-spherical alumina powder with a particle diameter of 32 microns;

[0032] The preparation process of the thermally conductive epoxy casting glue in this example is as follows

[0033] Ⅰ. Weigh 40g of bisphenol A epoxy resin, 25g of novolac epoxy resin, and 35g of cycloaliphatic epoxy resin, and mix them at 15°C for 30 minutes to form component A;

[0034] Ⅱ. Take 80g of methyl hexahydrophthalic anhydride as component B of anhydride curing agent

[0035] Ⅲ. Add component B to component A and mix for 40 minutes at 20°C;

[0036] Ⅳ. Take 40g of spherical alumina powder with a particle size of 1...

Embodiment 2

[0040] The components of the thermally conductive epoxy casting glue in this example are as follows:

[0041] A component, bisphenol F type epoxy resin 45g, glycidylamine type epoxy 55g;

[0042] Component B, tetrahydrophthalic anhydride 40g, methyl hexahydrophthalic anhydride 30g, methyl nadic anhydride 30g;

[0043] Component C, 55g of spherical silicon micropowder with a particle diameter of 10 microns, 40g of spherical boron nitride powder with a particle diameter of 4 microns, and 285g of non-spherical silicon micropowder with a particle diameter of 32 microns;

[0044] The preparation process of the thermally conductive epoxy casting glue in this example is as follows

[0045] Ⅰ. Weigh 45g of bisphenol F-type epoxy resin and 55g of glycidylamine-type epoxy resin, and mix them at 20°C for 25 minutes to form component A;

[0046] Ⅱ. Take 40g of tetrahydrophthalic anhydride, 30g of methyl hexahydrophthalic anhydride, and 30g of methyl nadic anhydride as component B of the...

Embodiment 3

[0052] The components of the thermally conductive epoxy casting glue in this example are as follows:

[0053] A component, bisphenol A type epoxy resin 100g;

[0054] Component B, 50g of hexahydrophthalic anhydride, 40g of methyl tetrahydrophthalic anhydride;

[0055] Component C, 40g of spherical silica powder with a particle size of 10 microns, 40g of spherical alumina powder with a particle size of 10 microns, 25g of spherical aluminum nitride powder with a particle size of 7 microns, and non-spherical alumina powder with a particle size of 32 microns Powder 245g;

[0056]The preparation process of the thermally conductive epoxy casting glue in this example is as follows

[0057] Ⅰ. Weigh 100g of bisphenol A type epoxy resin and mix it at 30°C for 25 minutes to form component A;

[0058] Ⅱ. Take 50g of hexahydrophthalic anhydride and 40g of methyltetrahydrophthalic anhydride as component B of the anhydride curing agent;

[0059] Ⅲ. Add component B to component A and mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com