Method for producing slide bearing, and slide bearing

A manufacturing method and sliding bearing technology, applied in the direction of sliding contact bearing, rotary motion bearing, bearing, etc., can solve problems such as high oil friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

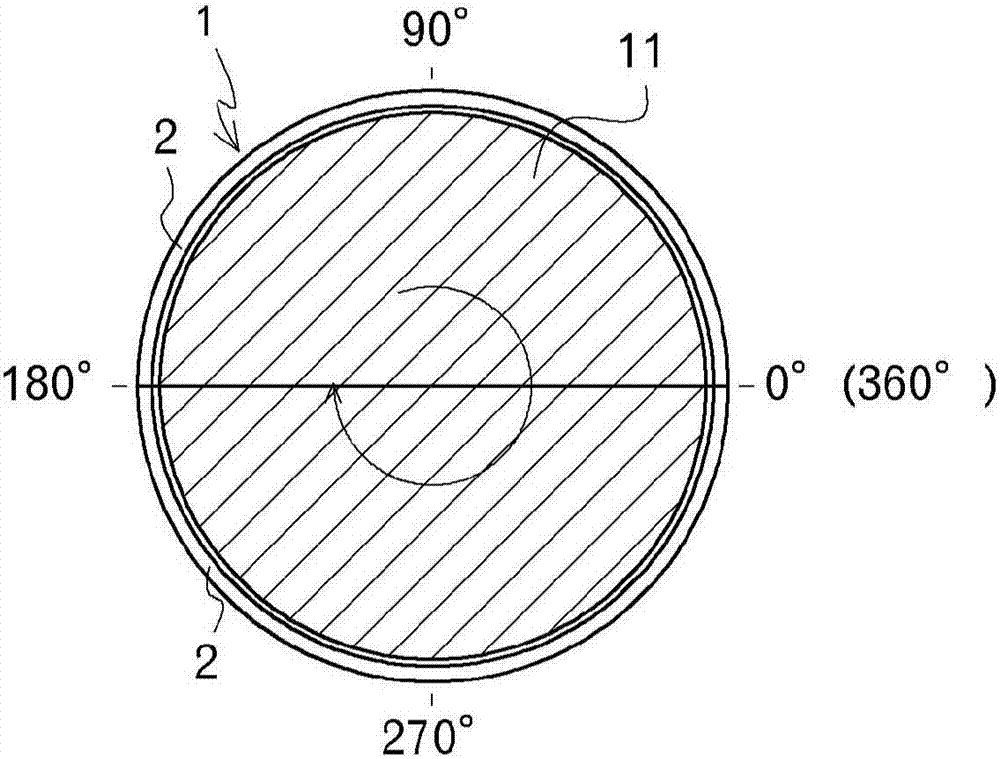

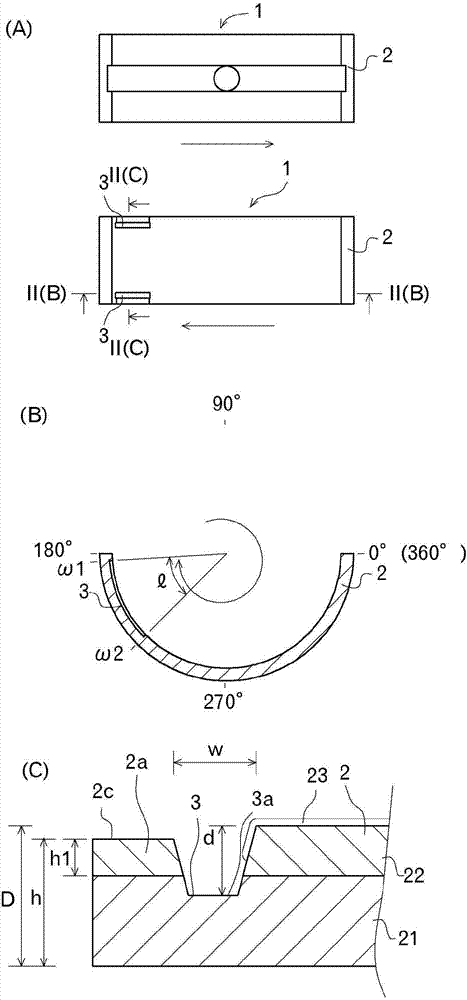

[0021] Next, embodiments of the present invention will be described. Notice, figure 1 is a front view of the sliding bearing 1, upward and downward in the drawings are considered as up-down directions, and front and rear directions in the drawings are considered axial directions (front-rear directions).

[0022] First, refer to figure 1 and figure 2 The half-body member 2 constituting the sliding bearing 1 according to the invention is described.

[0023] Sliding bearings 1 are cylindrical members and are suitable for applications such as figure 1 The plain bearing structure for the crankshaft 11 of the engine shown in . The plain bearing 1 is composed of two half-parts 2 . The two half-body members 2 are shaped into sections obtained by dividing a cylinder into two along a line parallel to the axial direction, and the half-body members 2 have a semicircular cross-section. In this embodiment, the half-body components 2 are arranged vertically, and their mating surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com