Inverter Control

A control device and inverter technology, applied in control systems, motor control, AC motor control, etc., can solve the problems of component cost, manufacturing cost, product cost impact, life reduction, power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

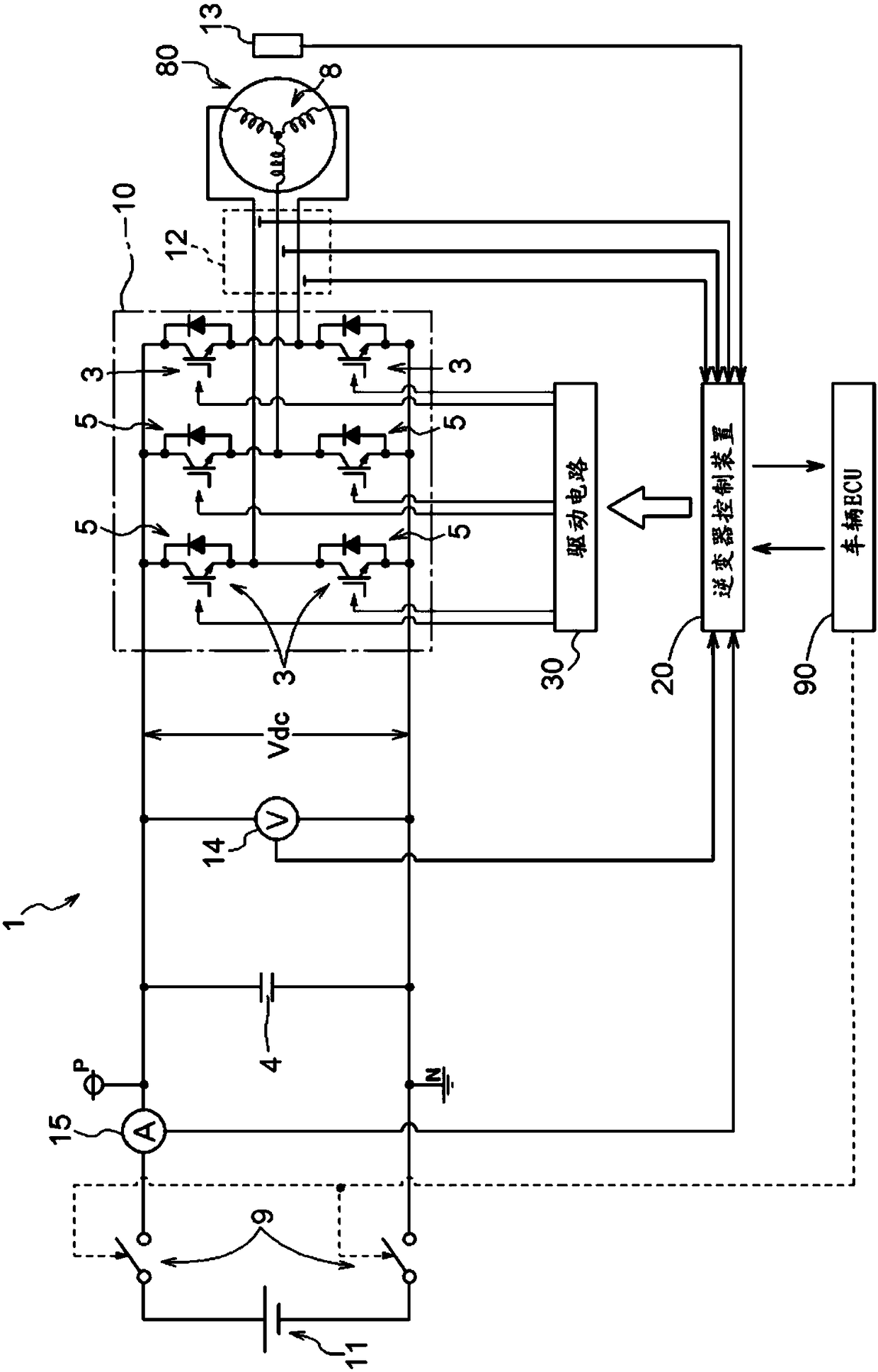

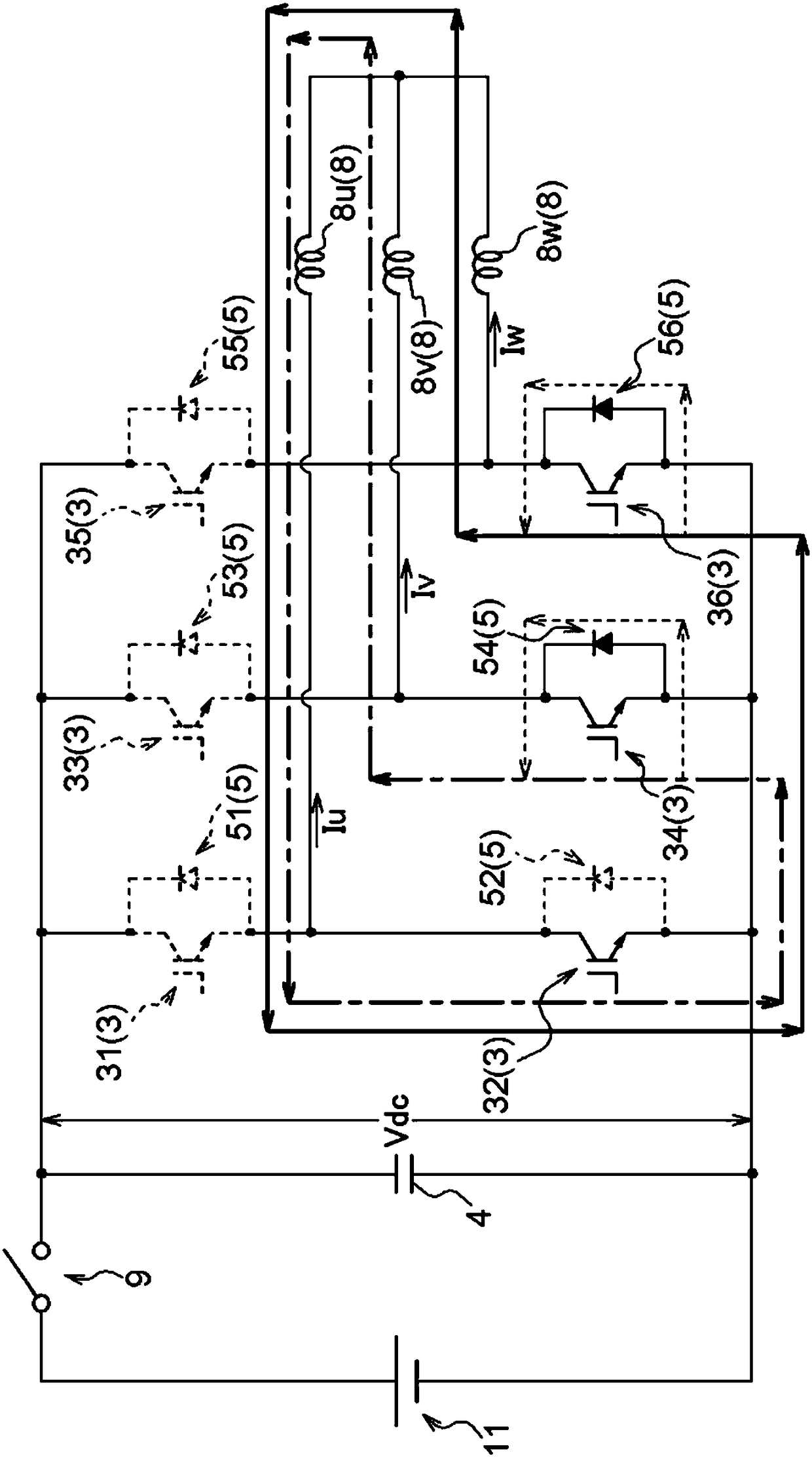

[0023] Hereinafter, embodiments of the inverter control device will be described based on the drawings. Such as figure 1 As shown, the inverter control device 20 takes the rotating electric machine driving device 1 including the inverter 10 and the DC link capacitor 4 as a control object, and drives and controls the rotating electric machine 80 via the rotating electric machine driving device 1 . As will be described later, the inverter 10 is connected to a DC power supply (11) via a contactor 9, and is connected to an AC rotating electrical machine 80, and performs electric power between DC and multi-phase AC (here, 3-phase AC). In the power conversion device for conversion, the arm of the AC 1-phase is constituted by a series circuit of an upper-stage side switching element and a lower-stage side switching element. The DC link capacitor 4 smoothes the DC link voltage Vdc which is the voltage on the DC side of the inverter 10 . The rotating electric machine 80 to be driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com