An assembly method of a single-sided magnetic tile clamp and a magnetic tile

An assembly method and a technology of magnetic tiles, which are applied in the manufacture of stator/rotor bodies, etc., can solve the problems of difficult assembly of magnetic tiles and magnetic tile clips, and achieve the effects of easy promotion and use, good assembly quality, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

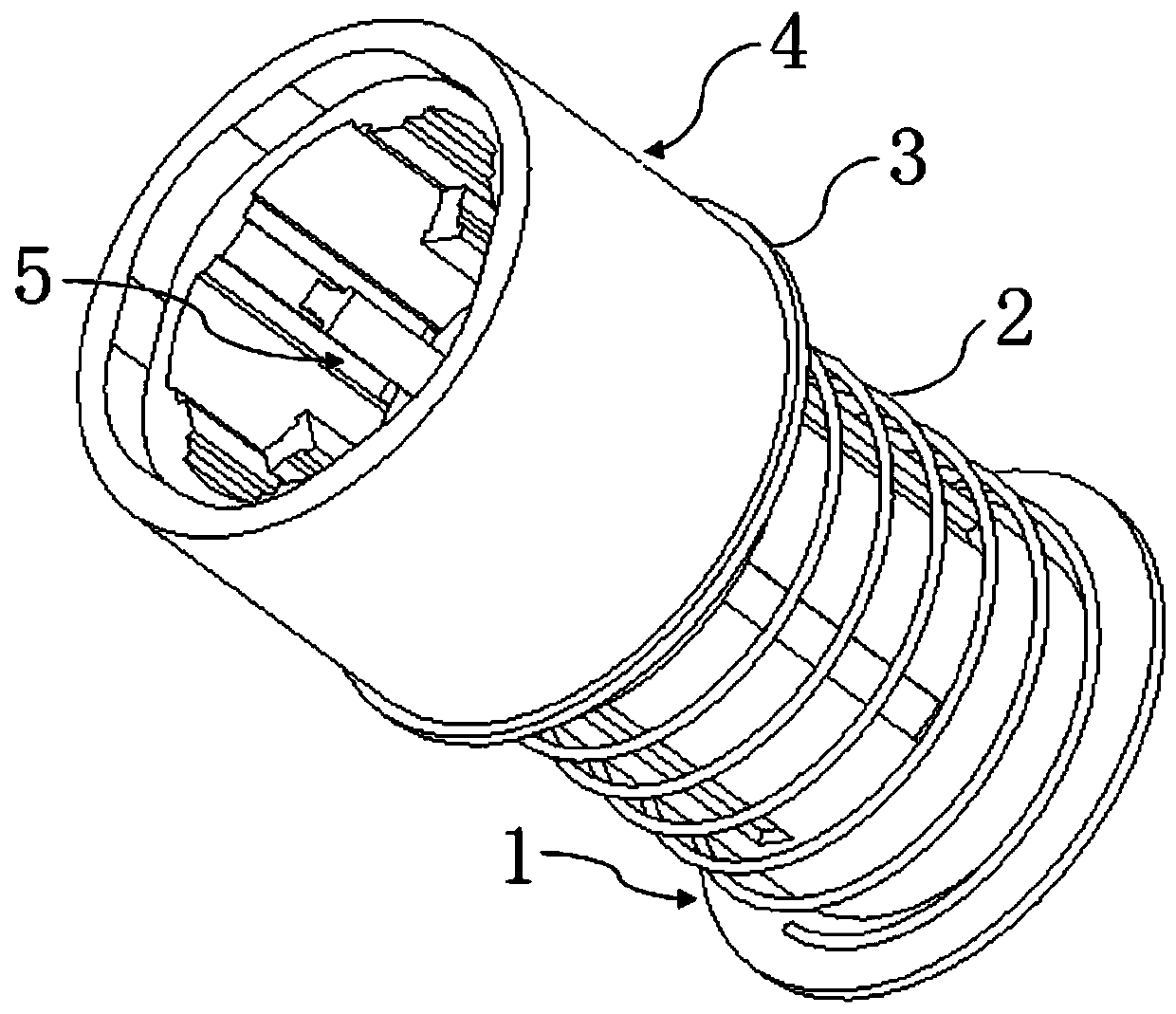

[0038] combine figure 1 , a unilateral magnetic tile clamp and magnetic tile assembly device in this embodiment, including: a support 1, a sliding sleeve 4 and a magnetic tile clamp stopper 5, a chute 13 is provided on the pillar 12 of the support 1, Its top is provided with center post 14; Sliding sleeve 4 can slide in vertical direction along pillar 12, is provided with magnetic tile clip stopper 5 above center post 14, and sliding sleeve 4 cooperates with magnetic tile clip stopper 5 to be able to magnetic tile and Magnetic tile clips are pre-installed.

[0039] The bottom of the pillar 12 in this embodiment is connected with a bottom plate 11, and the bottom plate 11 is used to prevent the pillar 12 from toppling over and improve its stability. The bottom plate 11 and the pillar 12 together form the support 1 for supporting other parts.

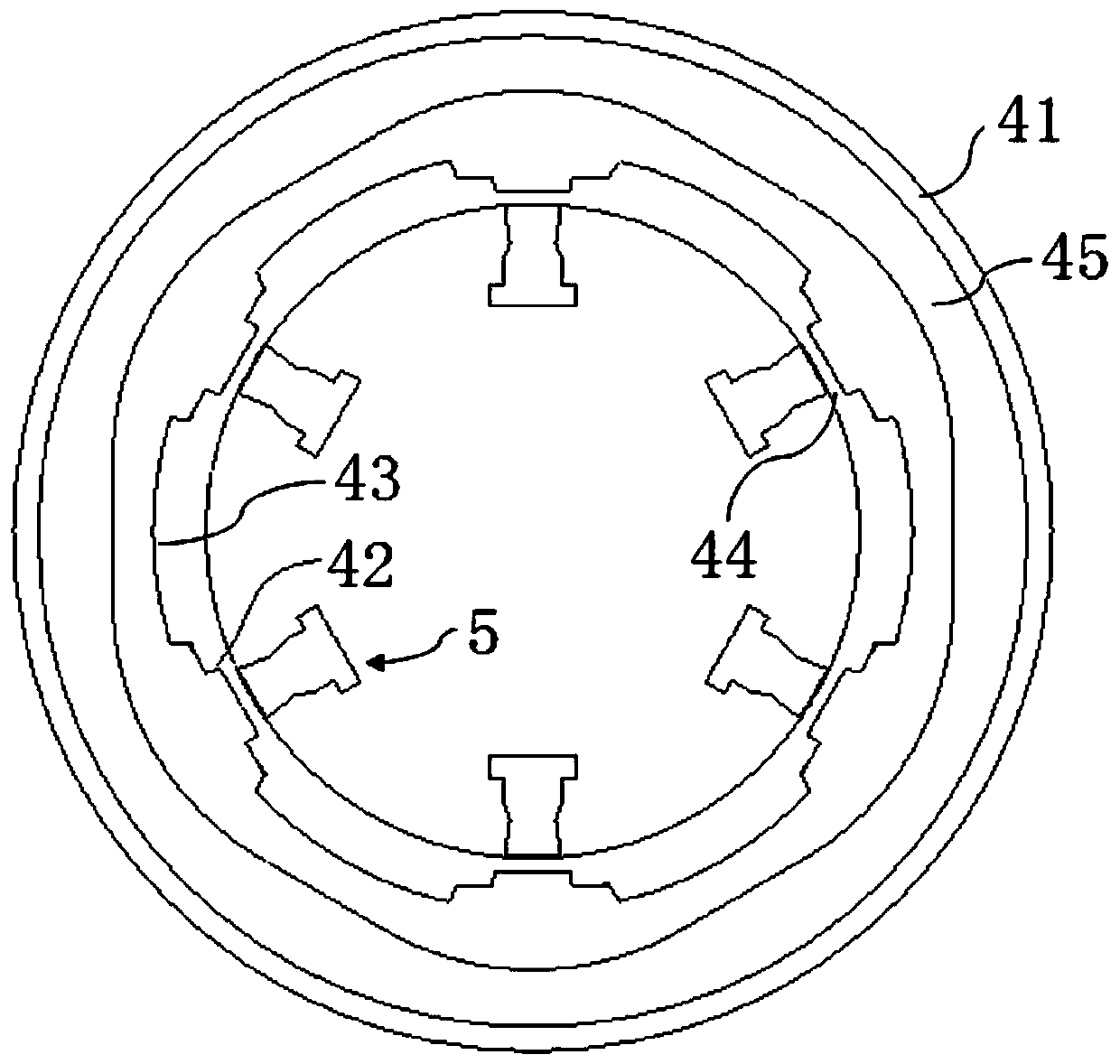

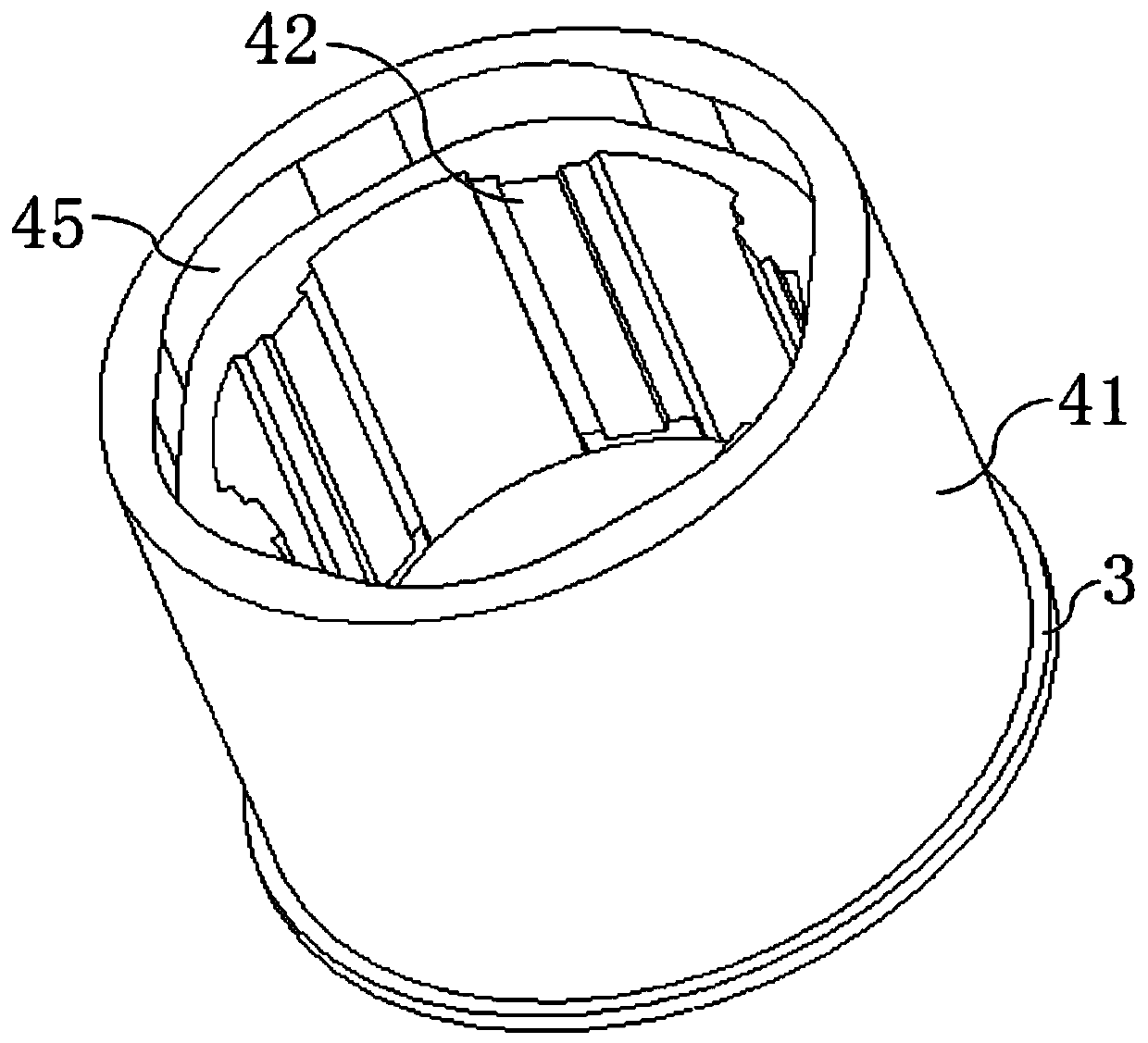

[0040] combine figure 2 , image 3 , The outer periphery of the pillar 12 is sleeved with a sliding sleeve 4, and the sliding sleev...

Embodiment 2

[0049] The basic structure of the unilateral magnetic tile clamp and magnetic tile assembly device of this embodiment is the same as that of Embodiment 1, the difference being that the positioning gap 44 extends to the bottom of the center column 14 in this embodiment. The position of the upper end of the magnetic tile clamp can be limited by the magnetic tile clamp block 5, and as a reference, the lower end gap mainly provides enough space for the magnetic tile clamp to be put into.

[0050] The positioning gap 44 is mainly used for accommodating the magnetic tile clamp. There is no special restriction on whether there is a gap between the side walls of other parts of the central column 14 and the sliding sleeve shell 41, provided that the magnetic tile can be placed.

[0051] Further, a spring connecting plate 3 is arranged between the returning spring 2 and the sliding sleeve 4 , the bottom surface of the spring connecting plate 3 is connected with the returning spring 2 , a...

Embodiment 3

[0053] combine Figure 5 , a unilateral magnetic tile clamp and magnetic tile assembly device of this embodiment, its basic structure is the same as that of Embodiment 2, the difference is that in this embodiment, the positioning bar 42 includes a positioning section 421 and a positioning section 2 422 , the positioning segment 421 on two adjacent positioning bars 42 is used for positioning the magnetic tile, and the positioning segment 422 cooperates with the chute 13 .

[0054] The magnetic tile can be positioned by positioning the first section 421 so that it cannot move to both sides. The second positioning section 422 can not only cooperate with the chute 13 for guidance, but also limit the position of the magnetic tile clamp. If only one overall positioning bar is set, the magnetic tile can be positioned when the width is sufficient, but the position of the magnetic tile clip cannot be restricted; it is difficult to meet the positioning requirements of the magnetic tile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com