A fluidized bed reaction process for preparing amino-terminated polyether

A technology of amino-terminated polyether and fluidized bed reaction, which is applied in the chemical industry and can solve problems such as low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

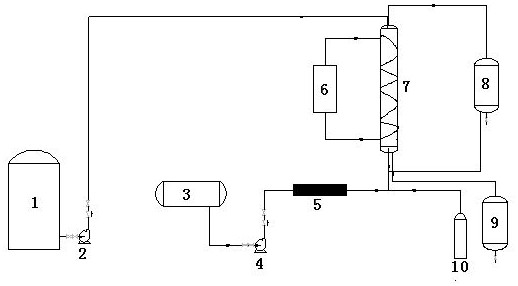

Method used

Image

Examples

Embodiment 1

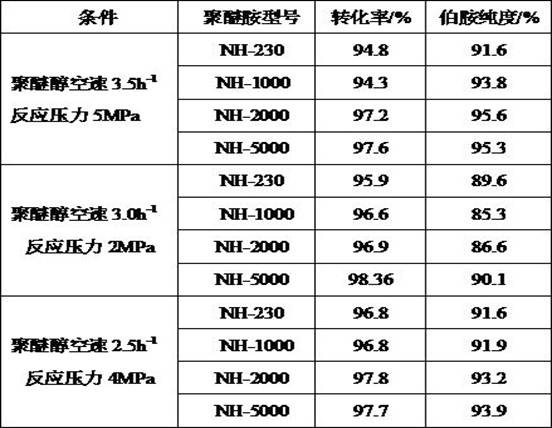

[0024] Use 10~20 mesh r-Al 2 o 3 Microspheres are used as a carrier to prepare a supported catalyst, in which the nickel content is 30%, the copper content is 10%, the catalyst loading volume is 50ml, and the liquid ammonia space velocity is 0.5h -1 , The reaction temperature is 230°C, and the results of synthesizing amino-terminated polyethers with different molecular weights are shown in Table 1.

[0025] Table 1 Example 1 reaction result

[0026]

Embodiment 2

[0028] Use 20~40 mesh r-Al 2 o 3 Microspheres are used as a carrier to prepare a supported catalyst, in which the nickel content is 40%, the copper content is 5%, the iron content is 3%, the catalyst loading volume is 50ml, and the liquid ammonia space velocity is 1.0h -1 , The reaction temperature is 250°C, and the results of synthesizing amino-terminated polyethers with different molecular weights are shown in Table 2.

[0029] Table 2 Example 2 reaction results

[0030]

Embodiment 3

[0032] Use 80~100 mesh r-Al 2 o 3 Microspheres are used as a carrier to prepare a supported catalyst, in which the nickel content is 35%, the copper content is 8%, the iron content is 5%, the catalyst loading volume is 50ml, and the liquid ammonia space velocity is 0.8h -1 , The reaction temperature is 245°C, and the results of synthesizing amino-terminated polyethers with different molecular weights are shown in Table 3.

[0033] Table 3 Example 3 reaction results

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com