Mass transfer Micro LED module, manufacturing method thereof, display screen and manufacturing method of display screen

A technology of LED modules and manufacturing methods, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor chip retention accuracy, low efficiency and yield, high IC power consumption, etc., and achieve low yield and power reduction. Consumption, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

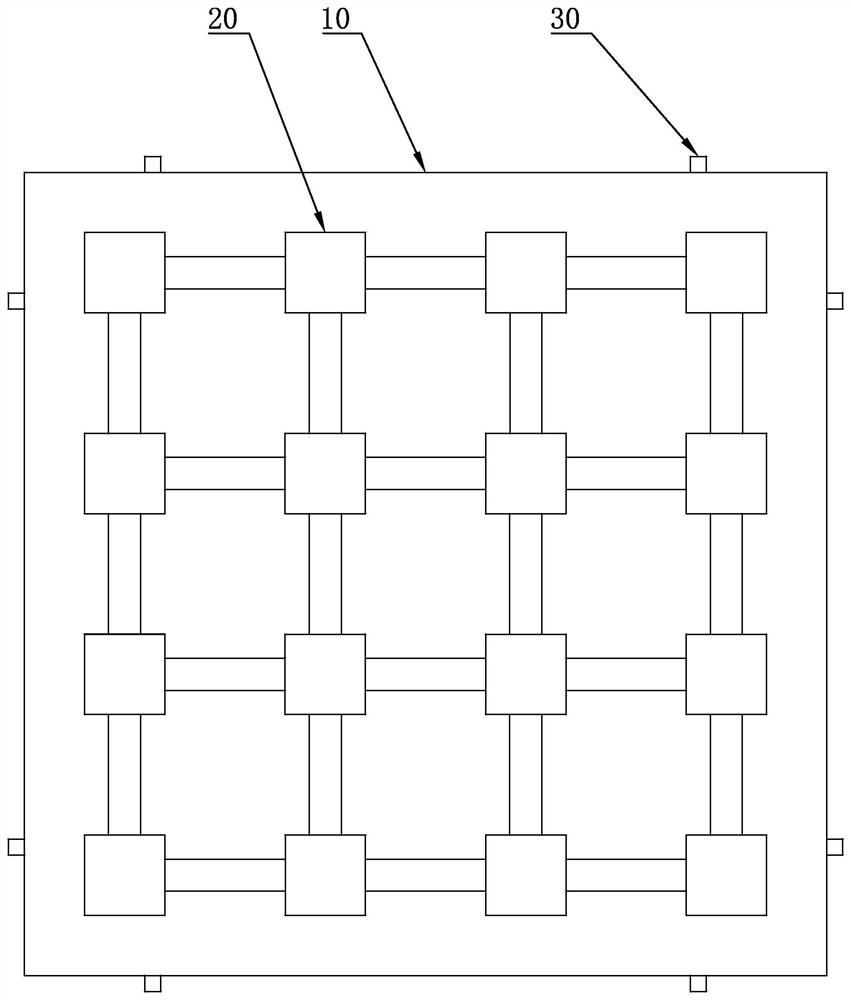

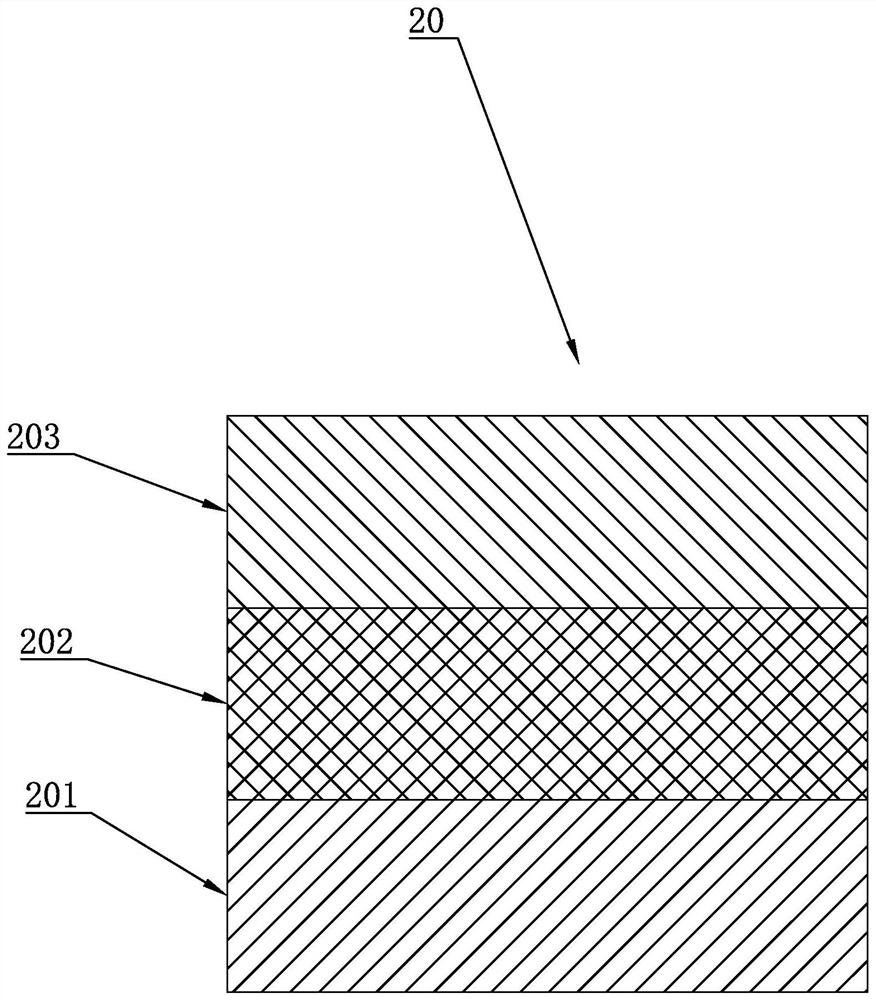

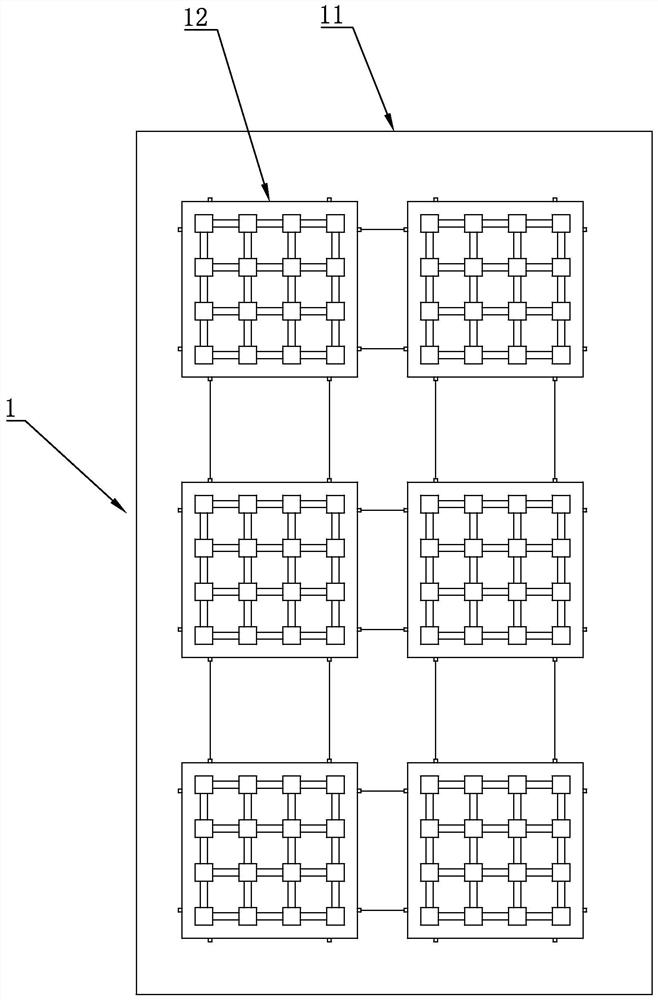

[0036] Such as Figure 1-4 As shown, the embodiment of the present application proposes a mass transfer Micro LED module, including a transfer module substrate 10, on which a three-in-one LED module 20 is arranged, and the three-in-one LED module 20 sequentially includes Display drive IC layer 201, drive control layer 202, LED chip layer 203, the three-in-one LED modules 20 are arranged in array on the transfer module substrate 10; Connected pin 30; the mass transfer MicroLED module integrates the display driver IC, drive control and LED chip to form a three-in-one LED module with its own driver, which avoids the low efficiency of die bonding caused by mass transfer , poor precision and low yield.

[0037] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com