Liquid lenses and liquid lens articles with low reflectivity electrode structures

A liquid lens, reflectivity technology, applied in the direction of lens, instrument, optics, etc., can solve problems such as air tightness combination problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

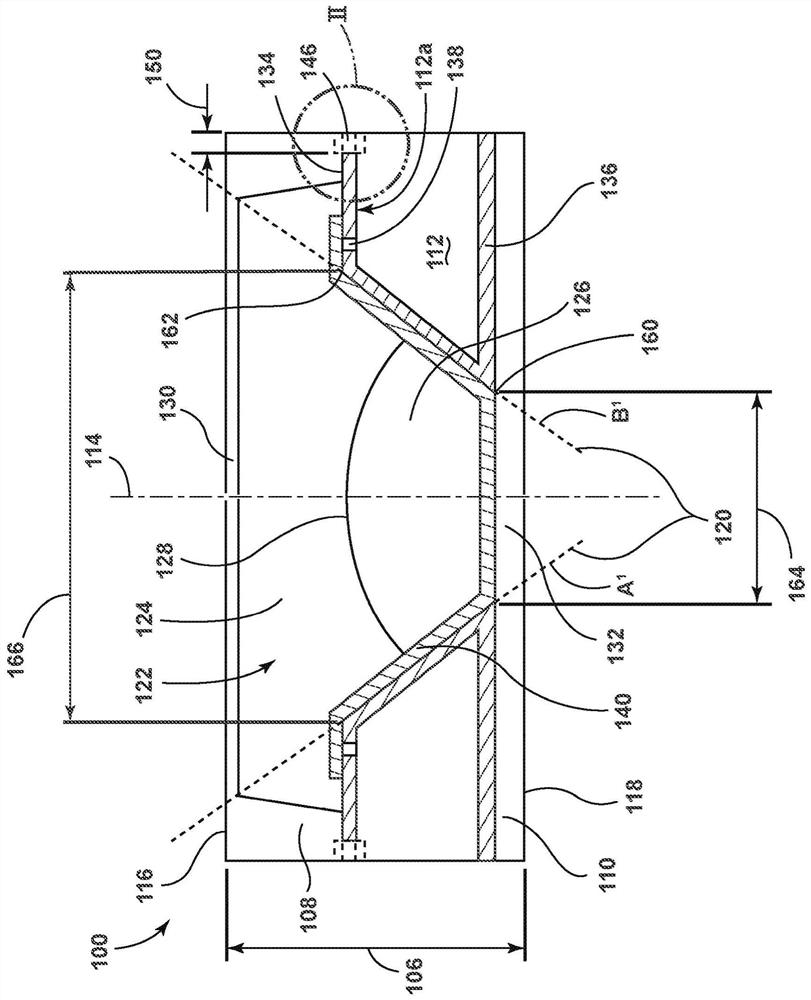

Image

Examples

Embodiment approach

[0027] As used herein, the term "about" means that amounts, dimensions, formulations, parameters, and other quantities and characteristics are not exact and need not be exact, but may be approximate and / or larger or smaller as required, such as to reflect tolerances, conversions factors, rounding, measurement errors, etc., and other factors known to those skilled in the art. When the term "about" is used to describe a value or an endpoint of a range, the disclosure should be understood to include the specific value or endpoint referred to. Whether or not a range value or endpoint is recited with "about" in the specification, the range value or endpoint is intended to include both embodiments: one modified with "about" and the other unmodified by "about." It should also be understood that the endpoints of each range are important both in relation to the other endpoints and independently of the other endpoints.

[0028] As used herein, the terms "substantially", "substantially"...

Embodiment 1

[0060] In this example, a liquid lens article 100a of the present disclosure was prepared (see Figure 2B ) consistent liquid lens preparation. As described in Table 1 below, the substrate has a glass composition, and the electrodes include the following layers disposed successively on the substrate: a Ni layer (e.g., conductive structure 134a) with a thickness of 80 nm; a Cr layer with a thickness of 15 nm (e.g., internal absorption device layer 234); and CrO with a thickness of 52 nm x N y layer (eg, outer absorber layer 236). This sample configuration is designated "Example 1".

[0061] Table 1 - Cr / ITO / Cr / ITO electrode (Example 1)

[0062] Material

thickness

glass substrate Ni film 80nm Cr film 15nm CrO x N y membrane

52nm Air N / A

[0063] now refer to Figures 3A-3C and 4A-4C, which are fabricated with comparative Cr / CrO x N y Electrode structure (comparative example 1) and Ni / Cr / CrO x N y electrodes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com