Screw-type material feeding device

A supply device, screw-type technology, applied in the directions of packaging, transportation and packaging, loading/unloading, etc., can solve problems such as inability to supply powder and granular materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

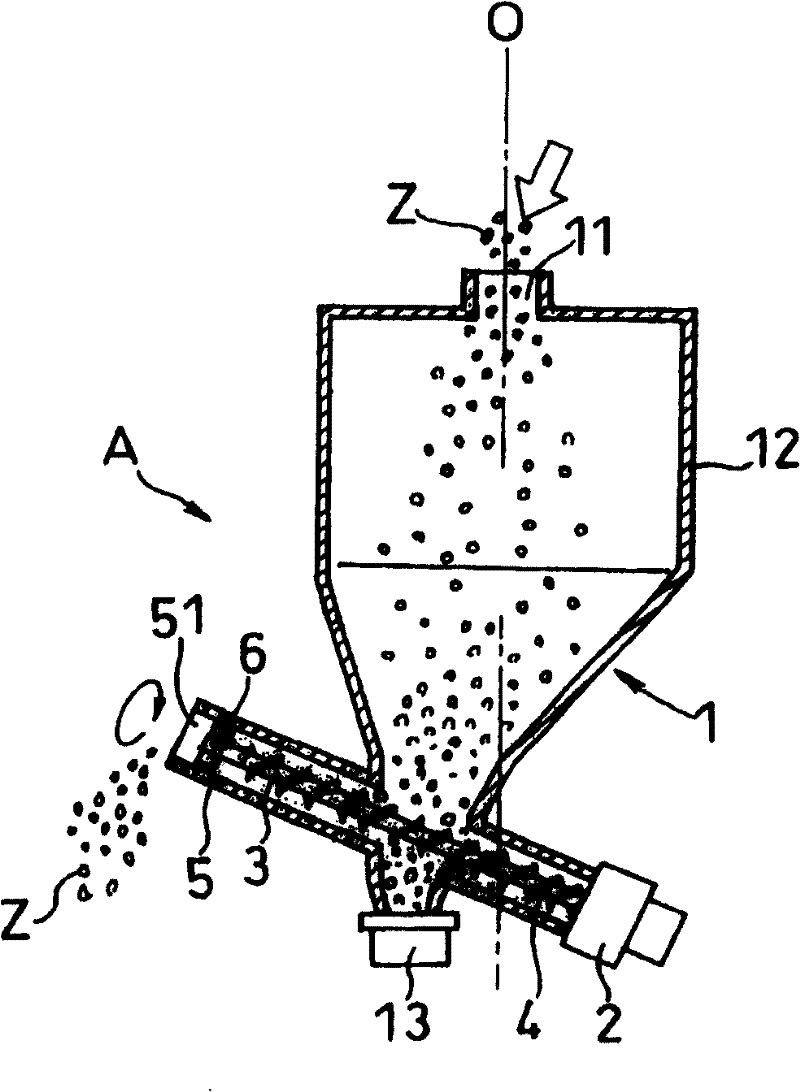

[0030] figure 1 It is a schematic overall perspective view showing an embodiment of the spiral material supply device A of the present invention; figure 2 seen from the side figure 1 Schematic longitudinal sectional view of . image 3 Partially enlarged for schematic cross-section figure 1 , figure 2 The essential parts of the invention represented in ; image 3 (a) is a partial perspective view, showing the top part of the helical rotating drive shaft provided with helical material conveying blades; image 3 (b) is a partial cross-sectional view, showing image 3 (a) the top end portion in a state where the helical rotation drive shaft is accommodated in the material supply cylinder; image 3 (c) Viewed from the direction of the material outlet image 3 (b) Front view.

[0031] The spiral material supply device A has: a rod-shaped spiral rotating drive shaft 3, which is arranged at the lower end of the hopper 1 storing the powder and granular material Z, and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com