Polypropylene (PP) is a thermoplastic polymer widely used for its excellent chemical resistance, mechanical strength, and processability. Derived from the polymerization of propylene monomers, it has become one of the most widely produced plastics globally.

In an era focused on sustainability, lightweighting, and cost-efficiency, polypropylene offers a unique balance of performance and recyclability. Industries from automotive to biomedical are investing in PP-based innovations to replace heavier, less sustainable materials.

This blog explores polypropylene’s molecular structure, key properties, comparative advantages, and emerging research trends. We also provide deep dives into nine application sectors—all supported by curated reports from PatSnap Eureka AI Agent.

Material Composition & Key Properties

Molecular Structure

- Linear hydrocarbon polymer composed of repeating units of C3H6

- Tacticity types: isotactic (high crystallinity), syndiotactic, and atactic

Key Physical & Chemical Properties

- High chemical resistance to acids, bases, and solvents

- Lightweight (density ~0.90 g/cm3)

- High tensile strength and modulus

- Excellent fatigue resistance

- Thermoplastic: melts at ~130–171°C

Typical Processing Methods

- Injection molding

- Extrusion

- Blow molding

- Thermoforming

Comparative Material Matrix

| Property | Polypropylene | Polyethylene | Polystyrene | Nylon |

|---|---|---|---|---|

| Density (g/cm3) | 0.90 | 0.94 | 1.05 | 1.14 |

| Melting Point (°C) | 130–171 | ~115 | ~240 | ~265 |

| Tensile Strength (MPa) | 25–35 | 10–20 | 45 | 75 |

| Chemical Resistance | Excellent | Very Good | Moderate | Good |

Comparative Advantages & Limitations

| Advantages | Limitations |

|---|---|

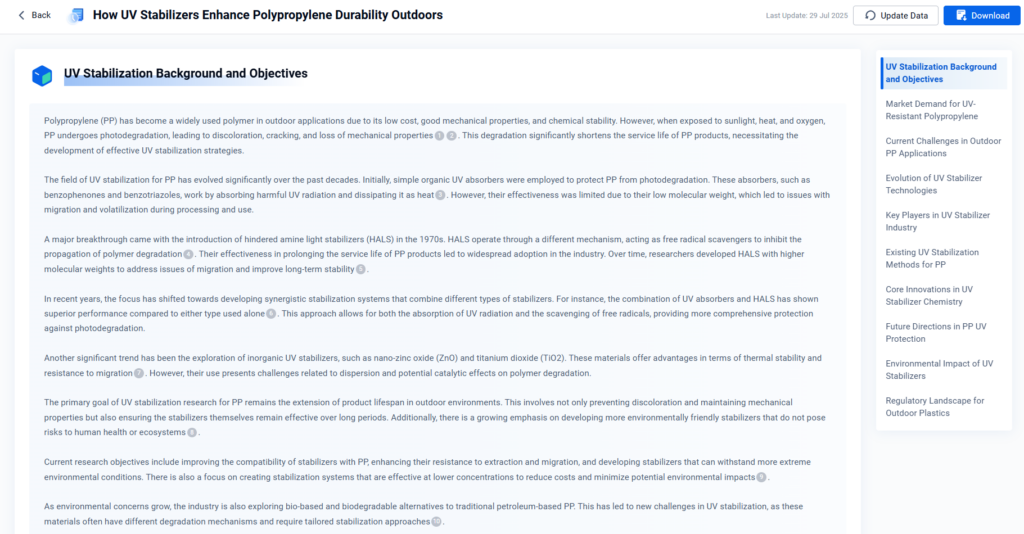

| Lightweight with high tensile strength | Poor UV resistance (requires additives for outdoor use) |

| Excellent chemical resistance and moisture barrier | Limited thermal stability above 100°C |

| Recyclable and cost-effective | Surface bonding and painting can be difficult without modification |

| Easily processable via multiple methods | Flammable without flame-retardant additives |

| High fatigue and impact resistance (esp. copolymers) | Brittleness at low temperatures unless modified |

| Low density enables energy-efficient transportation applications | Not biodegradable (though recyclable and reusable in circular systems) |

Application Domains

🧪 Materials Science & Performance Enhancements

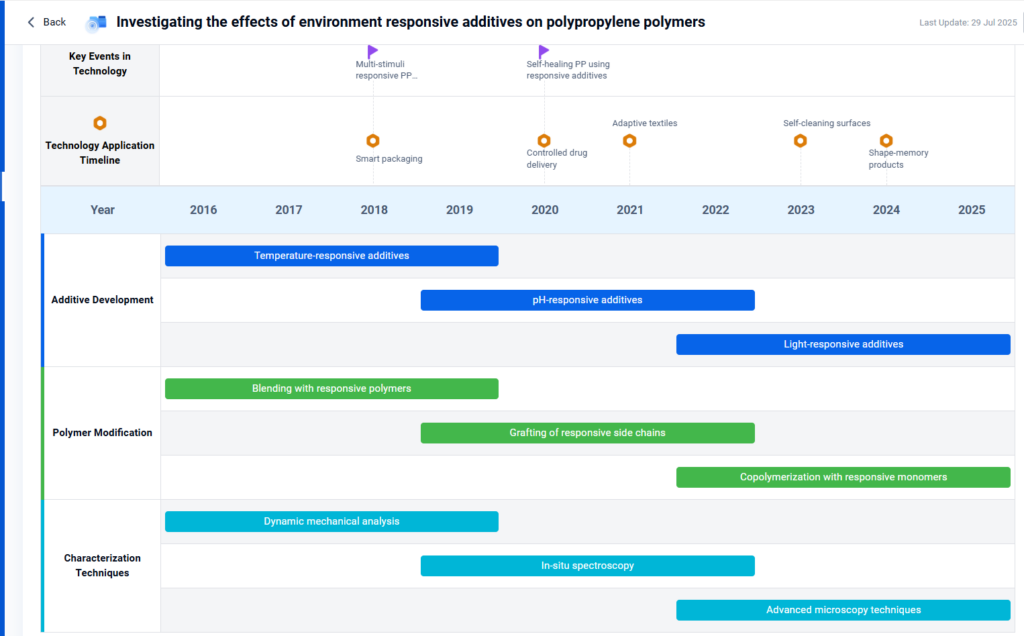

Advanced materials research continually seeks polymers that combine mechanical robustness, processability, and tunable properties to meet diverse engineering challenges. Polypropylene’s unique molecular structure allows for control over crystallinity and tacticity, enabling tailored mechanical strength, clarity, and fatigue resistance. Copolymerization and irradiation further expand its performance envelope, making PP a versatile base for high-performance composites and specialty applications.

Research Frontlines: Current studies investigate crystallization control, mechanical property optimization in random copolymers, high-modulus formulations for sports equipment, and effects of electron beam or UV irradiation on structural integrity.

Related Reports:

- How Crystallization Control Improves Polypropylene Clarity

- Investigating Mechanical Properties of Random Copolymer Polypropylene

- Exploring High-Modulus Polypropylene in Sports Equipment

- How Copolymer Additions Benefit Mechanically Toughened Polypropylene

- How Aligning Polypropylene Chains Affects Mechanical Properties

- Exploring Effects of Electron Beam Irradiation on Polypropylene

- Investigating UV-Induced Structural Changes in Polypropylene Membranes

- Investigating Stretch Blow Molding for Polypropylene Bottle Designs

- Exploring Polymeric Blends of Polypropylene for Viscosity Moderation

- Investigating Carbon Footprint Reduction via Polypropylene Innovations

- Investigating Long-Term Durability of Polypropylene Roofing Materials

🌍 Sustainability & Circular Economy

With increasing environmental regulations and consumer demand for green products, sustainable packaging requires materials that are recyclable, lightweight, and protective. Polypropylene meets these needs through clarity, barrier properties, and adaptability to multilayer films, enabling reduced material usage and improved shelf life.

Research Frontlines: Studies explore multilayer film innovations, high-impact printing techniques, and integration of recycled PP for circular economy solutions.

Related Reports:

- Polypropylene Recycling Methods for Enhanced Circular Economy

- Exploring Bio-Based Polypropylene’s Economic Feasibility

- How Sustainable Polypropylene Options Drive Eco-Friendly Textiles

- Exploring Biodegradable Polypropylene for Temporary Construction Uses

- Exploring Integration of Recycled Polypropylene in Home Product Design

- How Renewable Polypropylene Varieties Augment Circular Economies

- How Polypropylene Innovations Reduce Industrial Plastic Waste

- Investigating Life Cycle Assessment of Polypropylene Products

- How Circular Economy Principles Influence Polypropylene Tech Developments

🏗️ Construction & Infrastructure

The construction industry seeks materials that provide durability, thermal insulation, acoustic dampening, and chemical resistance under diverse environmental conditions. Polypropylene’s lightweight nature, resistance to moisture and chemicals, and versatility in composite formulations enable it to replace traditional heavier materials in geosynthetics, insulation panels, and façade systems.

Research Frontlines: Innovations target macro-additives to enhance mechanical properties, PP composites for marine engineering, and fire safety applications in building materials.

Related Reports:

- Polypropylene in Advanced Geosynthetic Applications for Infrastructure

- Investigating Polypropylene’s Role in Energy-efficient Insulation Panels

- Investigating Polypropylene Composites in Marine Engineering

- How Polypropylene Enhances Acoustic Insulation in Buildings

- Investigating Polypropylene Macro-Additives for Wall Application Innovations

- How Polypropylene Reinforcement Strengthens Seismic Safety Products

- Polypropylene’s Role in Modular Construction Innovations

🚗 Automotive & Aerospace

Reducing vehicle weight while maintaining safety and durability is crucial for meeting fuel efficiency and emission standards. Polypropylene’s toughness, thermal stability, and ability to be reinforced with fibers or nanomaterials make it ideal for under-the-hood components, shock absorbers, and lightweight composites. These applications contribute directly to improved vehicle performance and sustainability.

Research Frontlines: Focus areas include fiber-reinforced composites, shock absorption materials, and graphene-enhanced PP containers for automotive and aerospace applications.

Related Reports:

- How Polypropylene Upgrades Automotive Under-the-Hood Components

- Polypropylene’s Role in Shock Absorbing Automotive Components

- Polypropylene Nanocomposites in Aerospace Engineering

- How Graphene Additives Improve Polypropylene Graphene Containers

- How Fiber-Reinforced Polypropylene Drives Future Construction Materials

- Investigating Polypropylene’s Role in Low-Emission Material Circuits

- Exploring High-Performance Polypropylene in Composite Aerostructures

🏥 Medical & Healthcare

Modern medical devices and protective equipment require materials that are lightweight, biocompatible, and resistant to chemical and microbial challenges. Polypropylene offers excellent chemical resistance and biocompatibility, making it ideal for sterile environments, disposable medical textiles, and implantable devices. Its processability allows incorporation into advanced drug delivery systems and smart health monitoring tools.

Research Frontlines: Current efforts focus on enhancing PP’s functionalization for controlled drug release, smart hydrogels, and integration in wearable health sensors and surgical materials.

Related Reports:

- Investigating Polypropylene’s Role in Personal Protective Equipment

- Exploring Polypropylene Particle Applications in Biomedical Fields

- Polypropylene’s Contribution to Wearable Medical Device Advancements

- Exploring Polypropylene Suture Material Longevity in Healthcare

- Exploring Medical Polypropylene’s Non-Invasive Surgery Applications

- How Biocompatible Polypropylene Affects Medical Implants

- How Polypropylene Gels Facilitate Controlled Drug Release

- How Polypropylene Hydrogels Simplify Smart Medicine Delivery Systems

- Polypropylene in Real-Time Health Monitoring Systems

🌬️ Filtration, Insulation & Environmental Applications

Effective air and water filtration, thermal management, and noise reduction are essential across industrial and consumer products. Polypropylene’s ability to form nanofibers and porous membranes provides superior filtration performance, while its foam forms improve thermal insulation and acoustic attenuation. These properties contribute to healthier, more energy-efficient environments.

Research Frontlines: Studies focus on electrospun nanofibers, microporous structures, foam materials, and composite door sound attenuation.

Related Reports:

- Polypropylene-based Electrospun Nanofibers for Filtration Technologies

- How Nonwoven Polypropylene Enhances Air Quality in Ventilation Systems

- How Polypropylene Foam Materials Enhance Thermal Insulation

- How Polypropylene Enhancements Transform Air Filtration Efficiency

- Exploring Nano-Mechanical Properties of Microporous Polypropylene

- Investigating Sound Attenuation in Polypropylene Composite Doors

- How Polypropylene Enables Next-Gen Acoustic Materials

🧪 Functional Additives & Surface Properties

From UV stabilizers to nucleating agents, polypropylene (PP) has evolved into a key enabler in surface engineering. But how exactly do modified PP structures interact with external environments—be it water, heat, or chemical wear?

👉 Curious about how PP unlocks new functional possibilities at the surface level? Discover real-world studies and emerging technologies via PatSnap Eureka AI Agent.

Future Outlook & Research Frontiers

Polypropylene is at the frontier of both green chemistry and high-performance engineering. The future of PP research centers on these core areas:

- Functional Hybridization: Combining PP with nanofillers or bio-based resins

- Biodegradable Variants: Synthesizing green polypropylenes with microbial or enzymatic assistance

- Smart Surfaces: Responsive, antimicrobial, or optical properties via plasma or additive treatment

- AI-Guided Material Design: Leveraging ML to optimize formulation-performance relationships

Conclusion & Key Takeaways

Polypropylene remains a cornerstone material for scalable, high-performance, and sustainable innovation across sectors. Its evolving versatility—from bio-integrated designs to nanostructured surfaces—makes it a critical focus for engineers, designers, and sustainability leaders alike.

Whether you’re designing next-gen PPE or reinventing automotive interiors, polypropylene provides the mechanical, thermal, and ecological profile to make it possible.

Ready to unlock the full potential of polypropylene?

PatSnap Eureka AI Agent empowers your R&D team to explore untapped white spaces, visualize patent landscapes, and benchmark competitor innovations—all in one platform.👉 Request a PatSnap Eureka demo today.