Metallic packaging shell sintering method for controlling consistency of lead height

A metal encapsulation, consistent technology, applied in metal casing, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as increasing product cost, increasing equipment and processes, and the difficulty of lead preparation with inconsistent heights of wire bonding surfaces. Achieve the effect of improving production efficiency and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

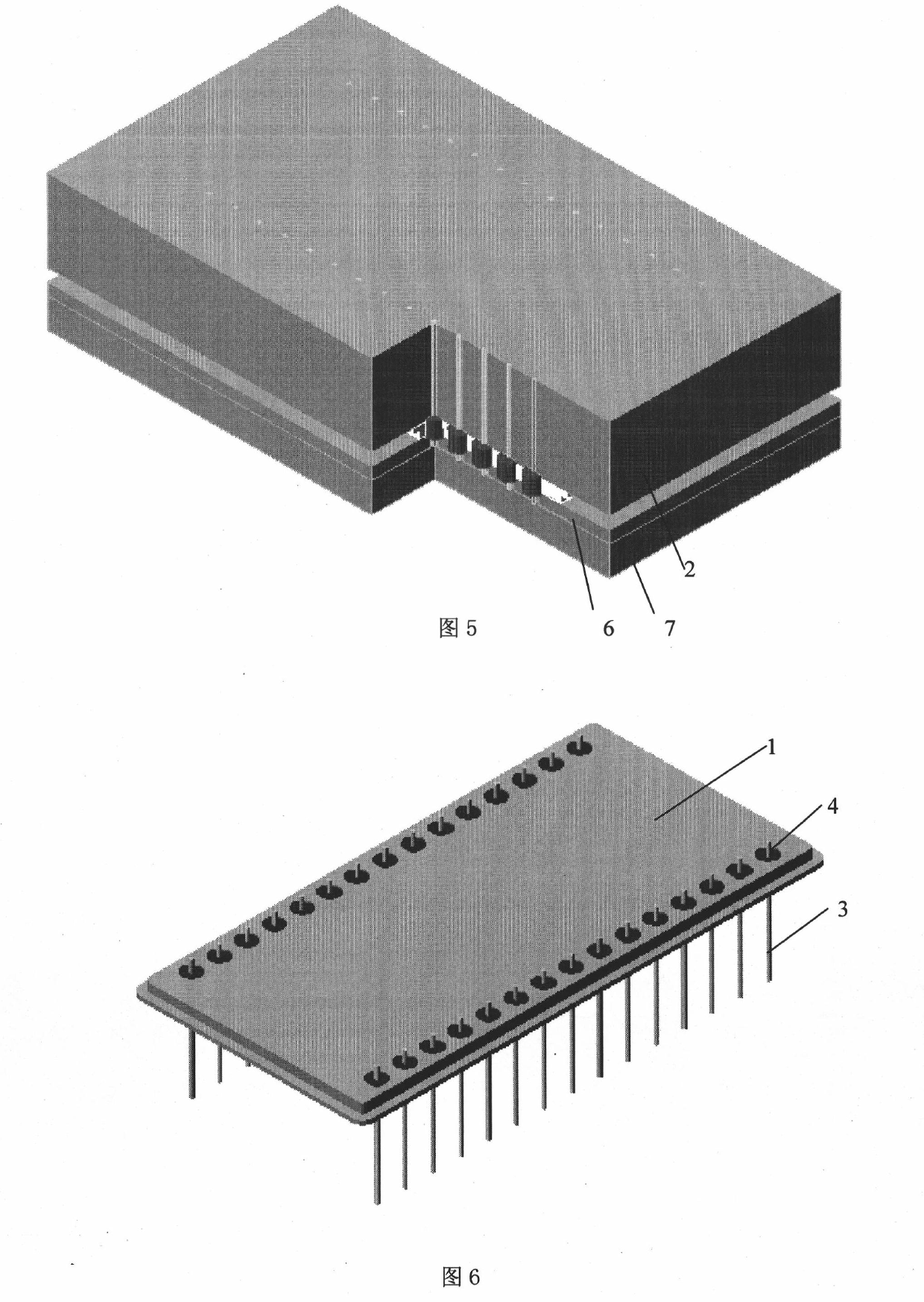

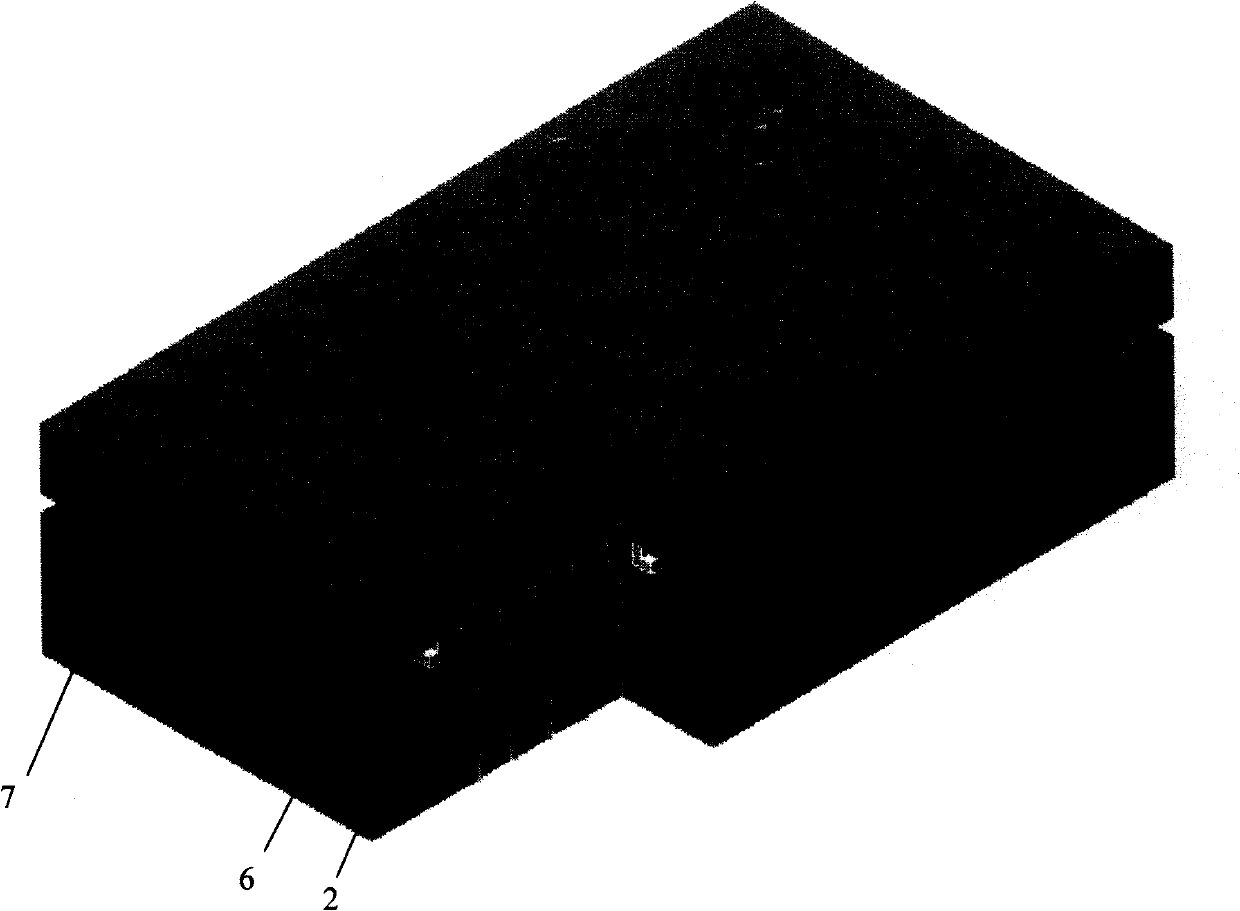

[0026] The invention discloses a method for sintering a metal package shell for controlling the height consistency of lead wires, which comprises the following steps:

[0027] Step 1. Place the bottom mold of the graphite mold on the mold bracket or worktable (not shown in the figure).

[0028] Step 2. Put the lead wire through the hole of the glass insulator, and then put the lead wire through the glass insulator into the corresponding hole on the bottom mold of the graphite mold, or use special equipment to screen the lead wire and the glass insulator into the corresponding hole of the mold middle.

[0029] Step 3, if figure 1 As shown, place the mounted chip on the flat bottom plate 1 of the metal package shell facing up (the cavity type shell has the cavity facing upwards) and place it on the corresponding position on the bottom mold 2 of the graphite mold, and place the insulator 4 with the lead wire 3 on the bottom plate corresponding holes. The bottom plate divides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com