Multi-functional fixing rack for welding test piece

A fixed frame, multi-functional technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of troublesome operation, high production cost, long production cycle, etc., and achieve convenient disassembly, transportation and storage. Convenient, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

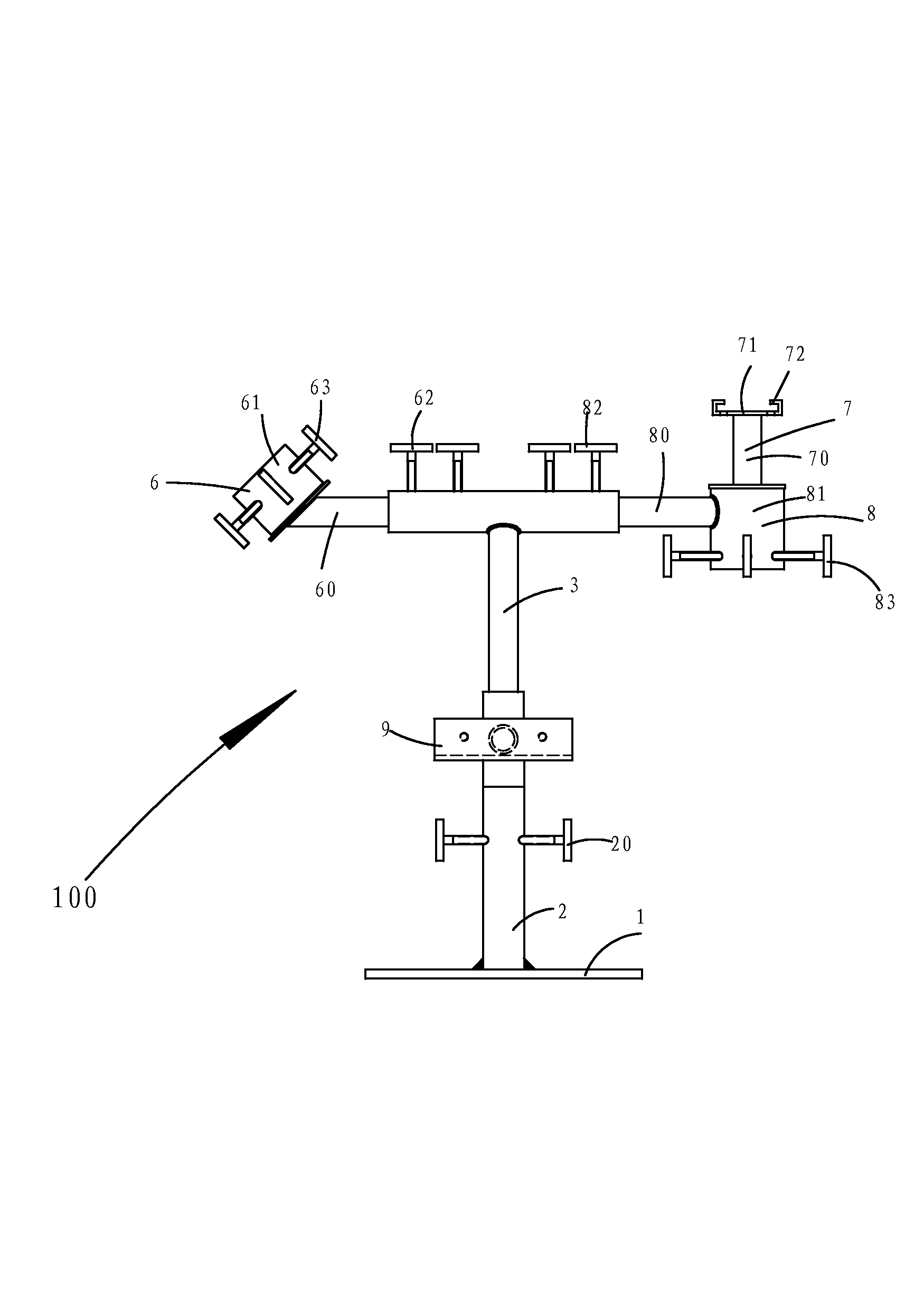

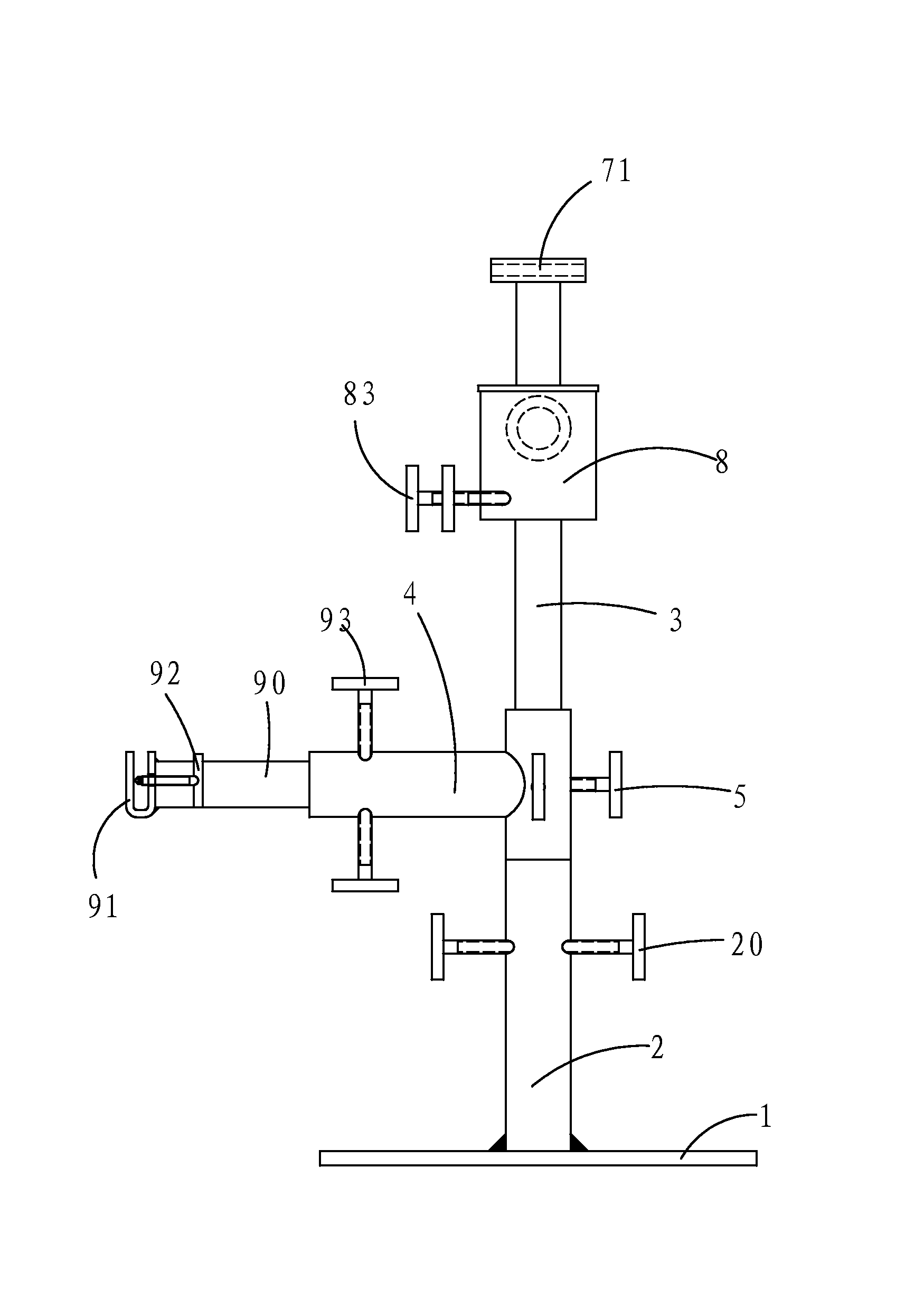

[0014] See figure 1 and figure 2 , A fixing frame 100 for a multifunctional welding test piece, comprising: a bottom plate 1, a column 2 fixed on the bottom plate 1, a T-shaped sleeve matched with the column 2 and fixed above the column 2 by a first fastening bolt 20 3 and the three-way pipe 4 sleeved on the column 2, the T-shaped sleeve 3, the three-way pipe 4 and the column 2 or the T-shaped sleeve 3 are fixed by a second fastening bolt 5, the T-shaped A 45° pipe butt welding auxiliary frame 6 is installed at one end of the sleeve 3, and a tube sheet fillet welding auxiliary frame 7 and a pipe horizontal butt welding auxiliary frame 8 are installed at the other end of the T-shaped sleeve 3. The three-way pipe 4 A small-diameter pipe butt joint, vertical plate and upper plate welding auxiliary frame 9 are installed. The height of the T-shaped sleeve 3 can be adjusted freely, and the height of the tee tube 4 can also be adjusted freely, so that it can be applied to people of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com