Transparent multi-layer circuit board

A multi-layer circuit and circuit board technology, applied in the direction of printed circuit components, etc., can solve problems such as scrap, defective, and lack of transparency, and achieve the effect of reducing abnormal hole deviation, reducing material waste, and feeding materials in advance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

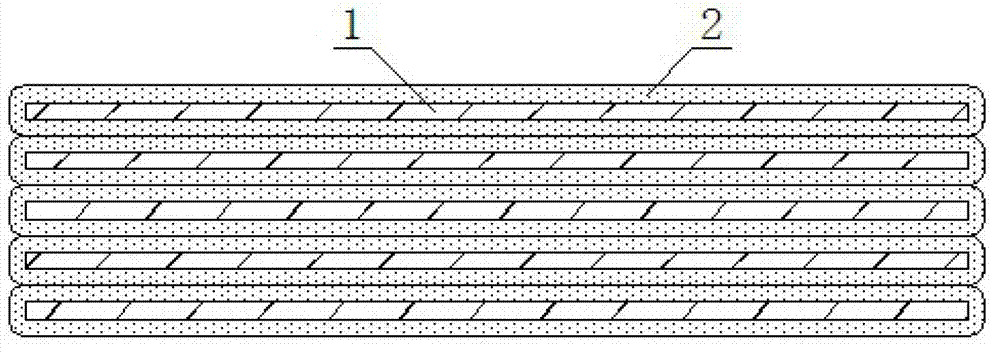

[0012] attached figure 1 It is a kind of transparent multilayer circuit board according to the present invention, which includes a multilayer circuit board body and an insulating layer 2; the multilayer circuit board body is formed by stacking a plurality of single-layer circuit boards 1; the insulating layer 2 Uniformly arranged on every single-layer circuit board 1; the thickness of the insulating layer 2 is 1 mm to 2 mm; the material of the insulating layer 2 is polymer transparent insulating ink.

[0013] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0014] The transparent multilayer circuit board of the present invention uses polymer transparent insulating ink to replace the traditional epoxy resin prepreg, so technicians can observe the inside of the multilayer circuit board, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com