Chain drive mechanism for grinding machine

A technology of chain drive and grinding machine, which is applied in the direction of transmission device, grinding drive device, grinding machine tool parts, etc., which can solve the problems of motor and reducer damage, low grinding precision, and inability to alleviate vibration, etc., to reduce vibration and relieve vibration. Vibration, effect of improving grinding accuracy and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

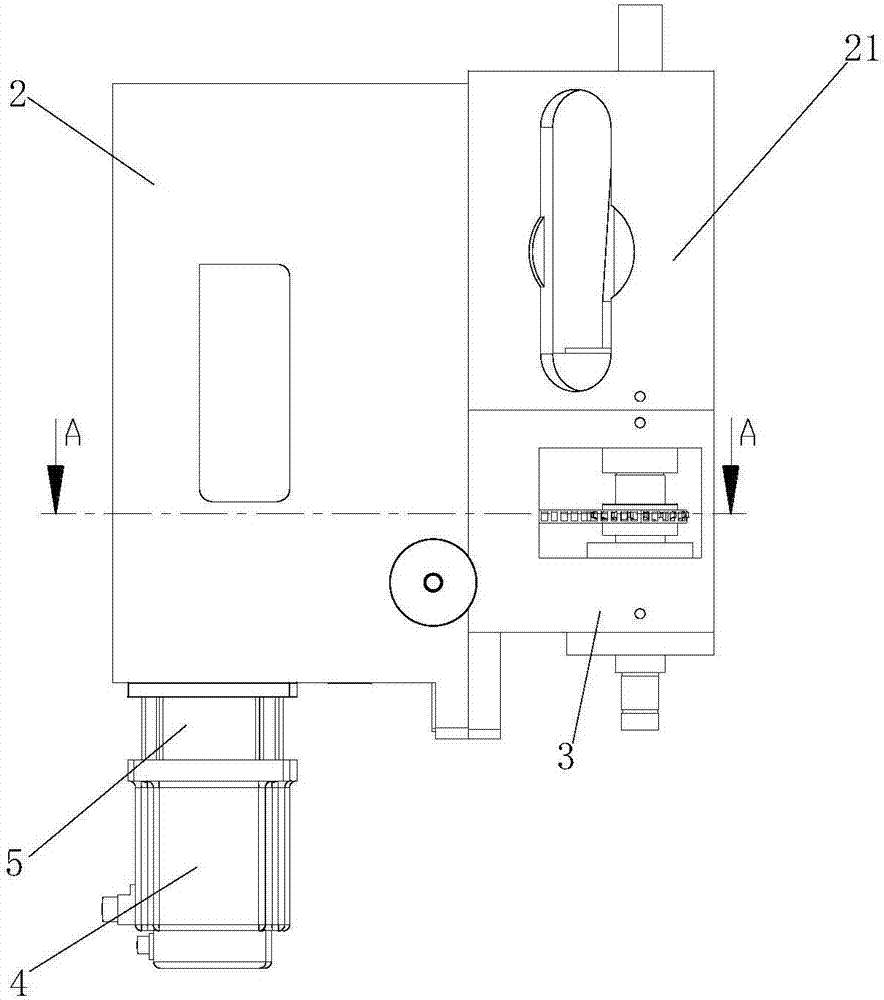

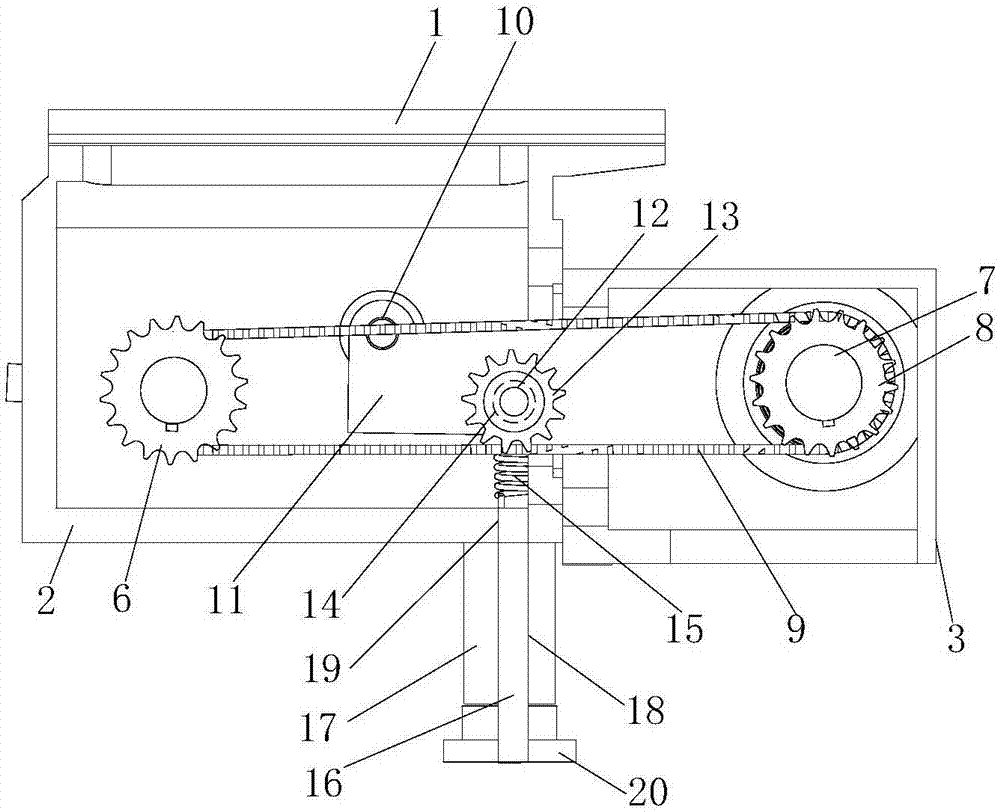

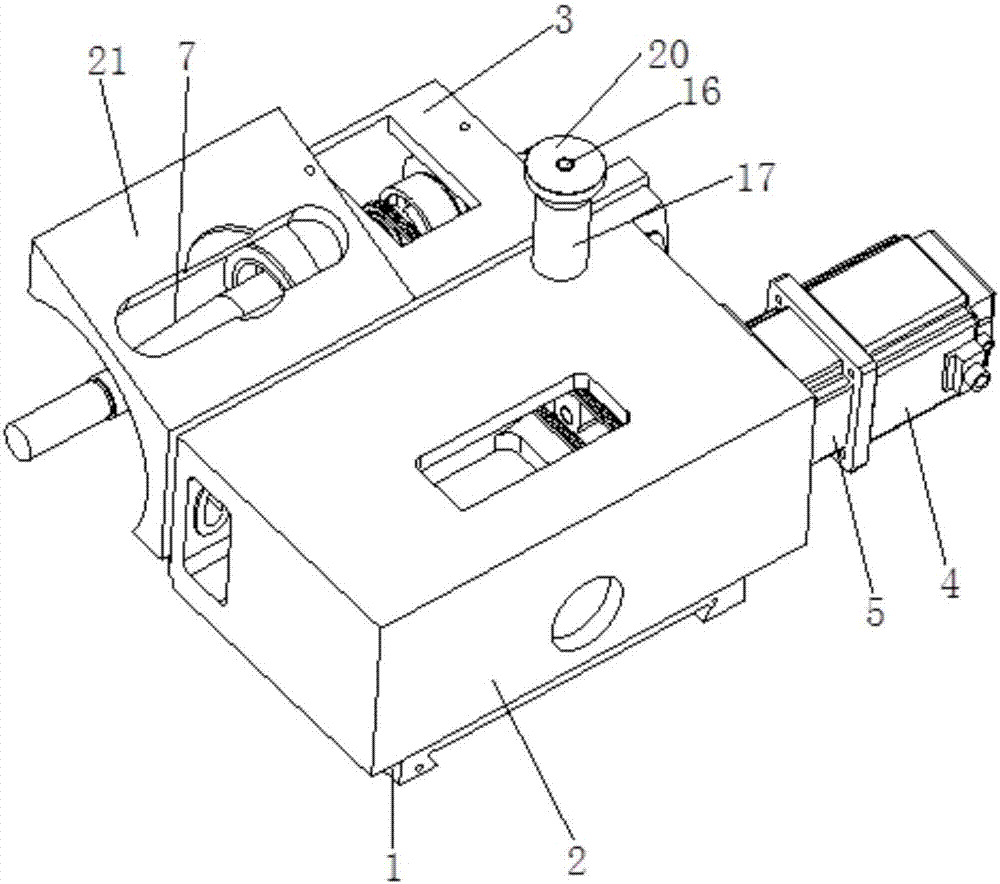

[0019] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a chain transmission mechanism for a grinding machine proposed by the present invention; figure 2 for figure 1 A-A sectional schematic diagram in ; image 3 It is an axonometric schematic diagram of a chain transmission mechanism for a grinding machine proposed by the present invention.

[0020] refer to Figure 1-3 , a chain transmission mechanism for grinding machines proposed by the present invention, including a bracket 1, a first housing 2, a second housing 3, a motor 4, a reducer 5, a driving sprocket 6, a guide shaft 7, and a driven sprocket 8 and chain9;

[0021] The first housing 2 is fixed on the bracket 1, and a slide groove is provided under the bracket 1 for fixed connection with the grinding machine, so as to facilitate reasonable adjustment of the relative position with the grinding machine, thereby improving the accuracy and applicability of grinding.

[0022] The motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com