Cooling unit for synthetic yarn

A cooling device, wire technology, used in textiles and papermaking, etc., can solve problems such as cooling liquid infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

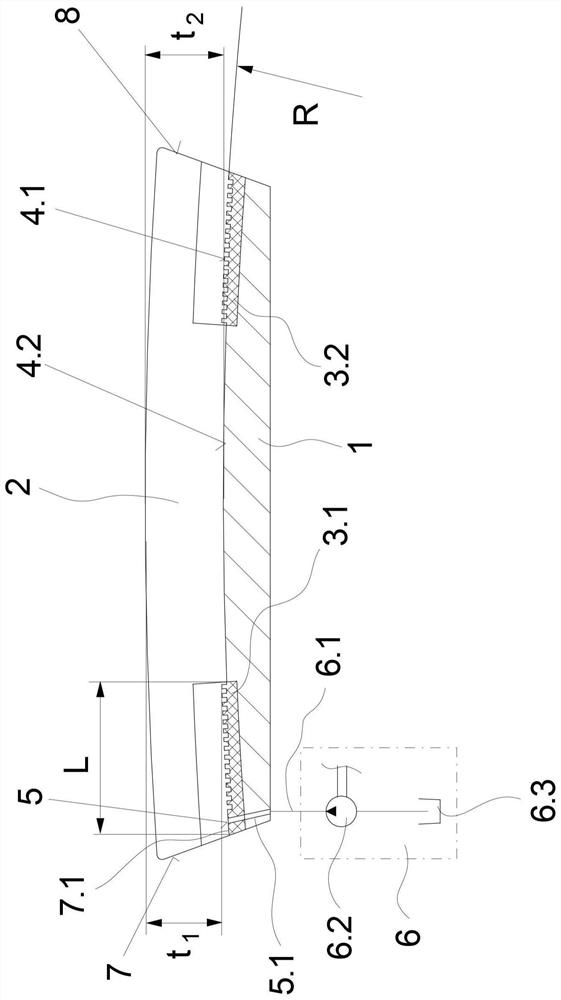

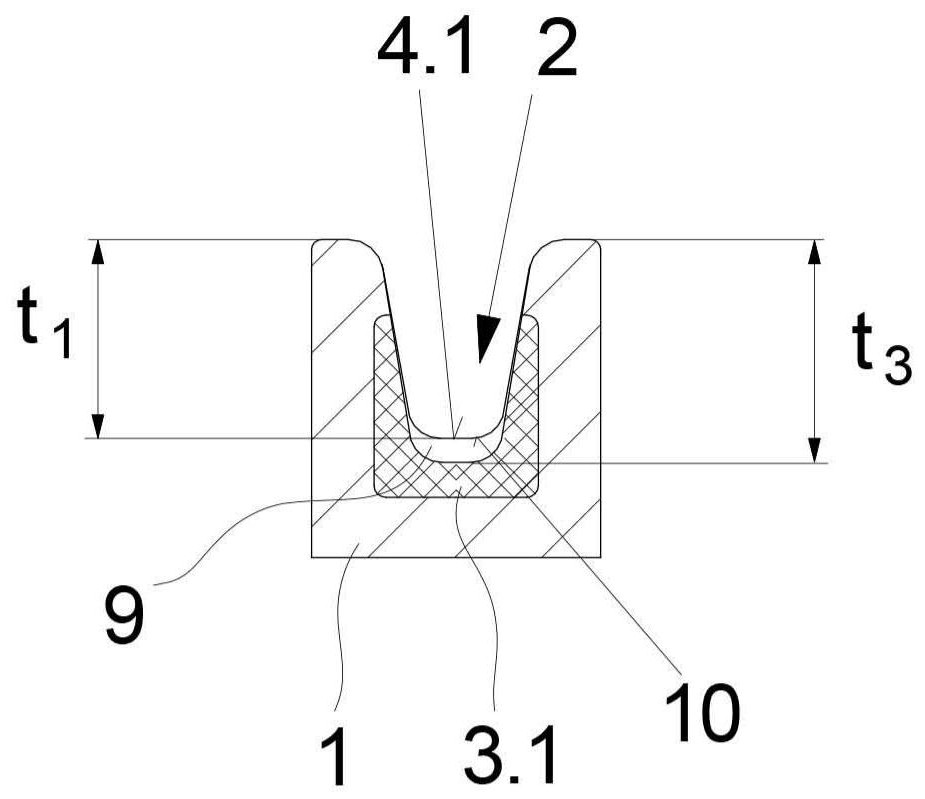

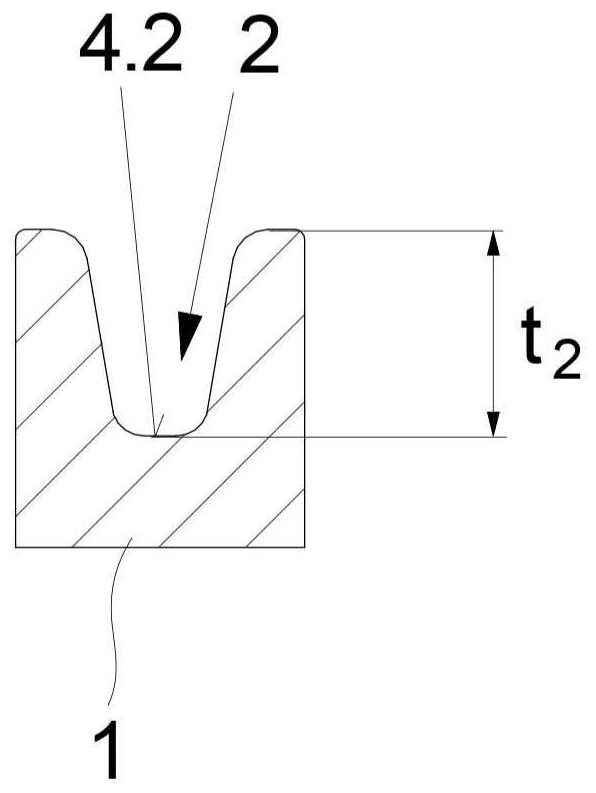

[0023] exist figure 1 , Figure 2.1 and Figure 2.2 , a first exemplary embodiment of a cooling device according to the invention is illustrated in several views. figure 1 Schematically shows a longitudinal sectional view of the cooling device according to the invention, in Figure 2.1 and Figure 2.2 A cross-sectional view of a cooling device according to the invention is shown in each case. In the absence of explicit reference to any one of the figures, the following description applies to said figures.

[0024] A first exemplary embodiment of a cooling device according to the invention comprises an elongated radiator 1 . An open cooling groove 2 extends on the upper side of the heat sink 1 . The cooling groove 2 extends between a wire inlet 7 and a wire outlet 8 formed at the end face of the heat sink 1 . At the wire entry 7 , the ceramic insert 3 . 1 is held in the cooling groove 2 on the heat sink 1 . The ceramic insert 3.1 is integrated in the cooling groove 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com