Mask plate assembly, cutting device and method for cutting initial flexible display panels

A flexible display and display panel technology, applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve the problems of flexible display panel warping, affecting product yield, and unfavorable flexible display panel narrow frame and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

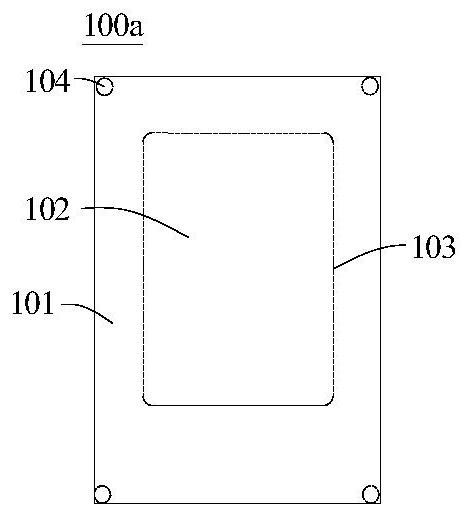

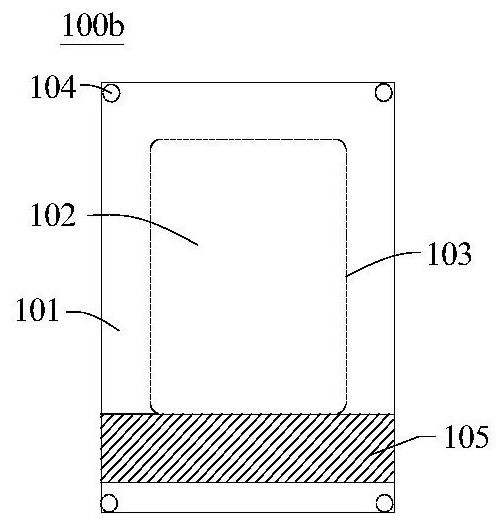

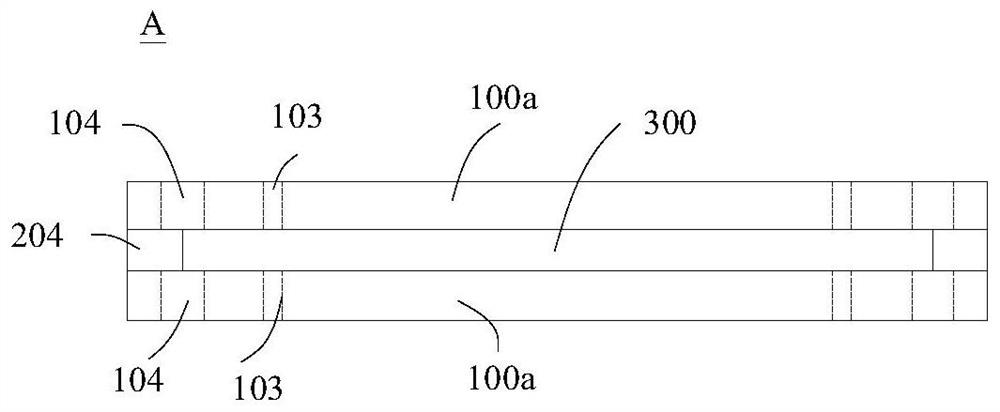

[0039] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0040] After repeated research by the inventors of the present invention, it was found that the flexible display panel after cutting in the prior art is prone to warping and bubbles at the edge of the cutting area, and the reason why the size of the heat-affected zone and the size of the carbonized area are relatively large in:

[0041] In the prior art, a single laser beam is directly used for cutting without any shielding of the initial flexible display panel. During the cutting process, the laser beam first hits the upper surface of the flexible display panel. At this time, due to The structure of the film layers in the structure of the flexible display pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com