A kind of refining production line and method of 1,3-propanediol

A technology of propylene glycol and production line, applied in 1 field, can solve the problems of difficult separation, complex composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

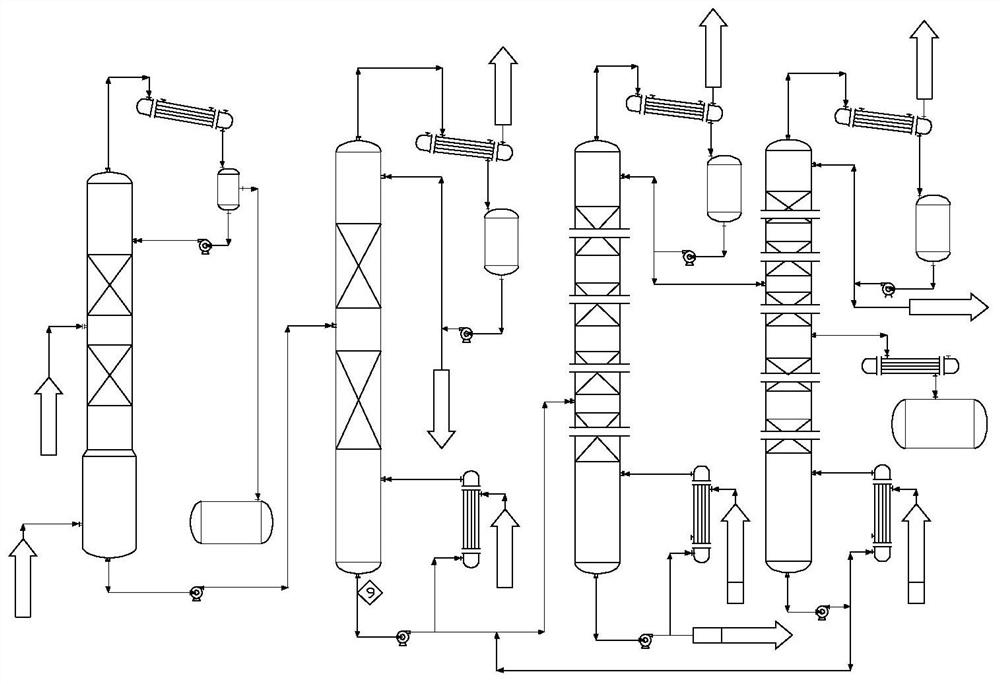

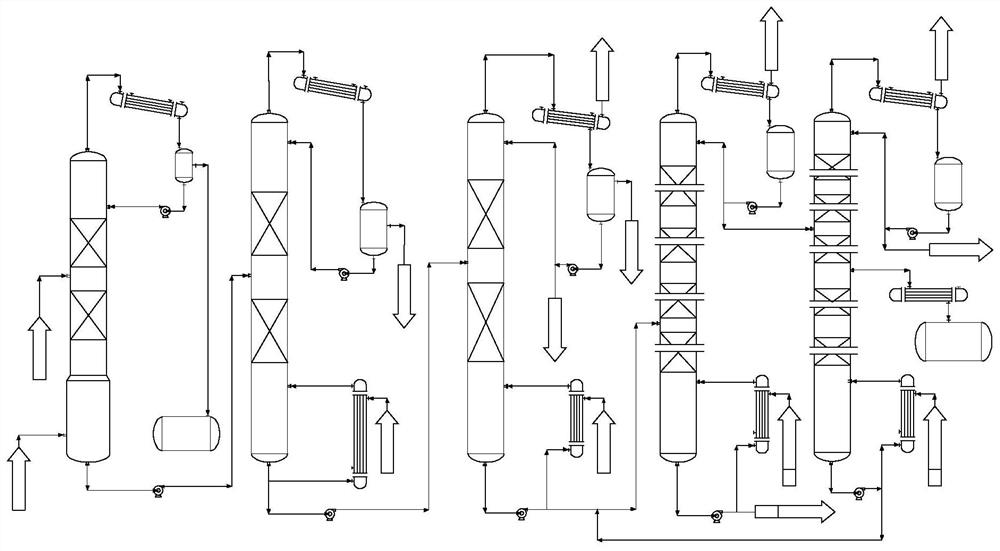

[0092] use figure 1 The 1,3-propanediol refining line shown performs the refining of the crude 1,3-propanediol product solution:

[0093] A) 1,3-propanediol thick product solution enters the stripping and delighting tower, and the stripping tail gas drawn from the top of the stripping and delighting tower is collected after condensation or is returned to the stripping and delighting tower, the 1 after the bottom stripping, The 3-propanediol crude product solution enters the pressurized dehydration tower. Among them, the temperature at the top of the stripping and lightening tower is 99.5°C, the temperature at the bottom of the tower is 113°C, the operating pressure is 0MPa, and the reflux ratio of the tower is 8. The content of light components whose boiling point is lower than that of water in the 1,3-propanediol crude product solution treated by the stripping tower is less than 0.2%.

[0094] B) After being treated by the pressurized dehydration tower, one stream of the to...

Embodiment 2

[0103] use figure 1 The 1,3-propanediol refining line shown performs the refining of the crude 1,3-propanediol product solution:

[0104] A), B), C), D) related process parameters are consistent with Example 1,

[0105] E) after 1,3-propanediol solution is processed by the refining tower, the light alcohol removed at the top is condensed and refluxed in the refining tower or collected and processed, the refining 1,3-propanediol extracted in the middle is collected after condensation, and the bottom is separated to obtain The heavy components are sent to the weight removal tower again for processing. Wherein, the temperature at the top of the purification tower is 80°C, the absolute operating pressure is 4kPa, the reflux ratio of the tower is 2, and the temperature at the bottom of the tower is 170°C. Due to the higher temperature of the tower still, the degradation of 1,3-propanediol is caused, and the purified The purity of 1,3-propanediol was 99.4%, and the yield of 1,3-pr...

Embodiment 3

[0107] use figure 1 The 1,3-propanediol refining line shown performs the refining of the crude 1,3-propanediol product solution:

[0108] A) Relevant process parameters are consistent with Example 1

[0109] B) After being treated by the pressurized dehydration tower, one stream of the top steam is returned to the stripping and delighting tower as the stripping steam, and the other stream enters the refrigerator to drive the refrigerator to prepare chilled water for heat recovery and utilization; the material passing through the refrigerator It is refluxed into the pressure dehydration tower or used for raw material deployment; the concentrated 1,3-propanediol solution at the bottom of the pressure dehydration tower enters the vacuum dehydration tower. Among them, the temperature at the top of the pressurized dehydration tower is 125°C, the operating pressure is 30kPa, the reflux ratio of the tower is 0.3, and the temperature at the bottom of the tower is 143°C. After dehydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com