Method for braking a traction sheave elevator

A technology of elevators and rope pulleys, which is applied to lifting equipment, elevators, transportation and packaging in mines. It can solve the problems of passengers bumping and falling, achieve long service life and expand the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

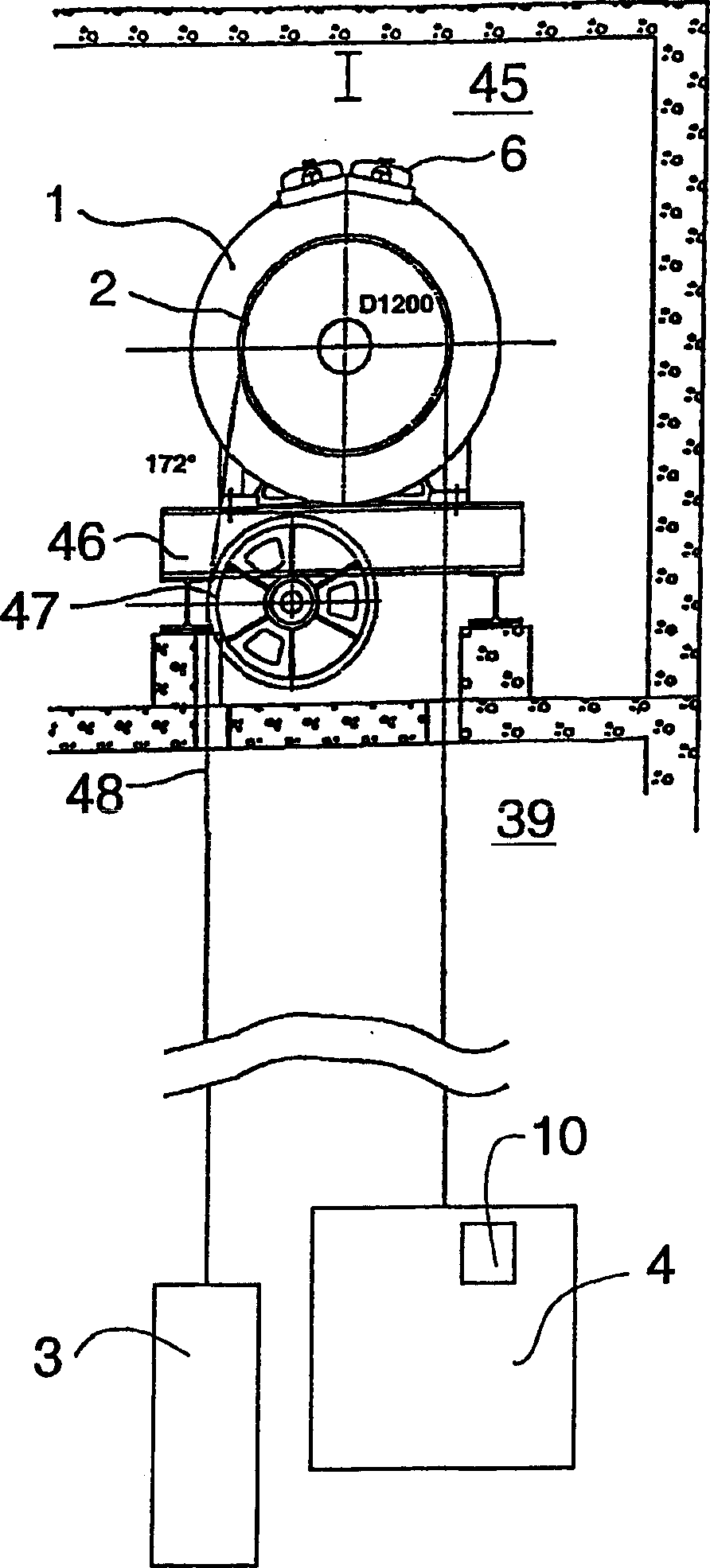

[0018] figure 1 The placement of an elevator drive machine 1 in a machine room 45 above an elevator passage 39 is indicated. The drive machine rests on a mounting base 46 constructed of steel beams. The distance between the sections of hoisting ropes 48 going towards the counterweight 3 and the car has been increased by arranging a diverting pulley 47 so that this distance is slightly greater than the distance corresponding to the diameter of the traction sheave 2 . The brake 6 of the drive machine mainly acts as a hold brake when the elevator is stationary. The preferred method of braking the elevator is electric braking. Generally, in electric braking, the motor brakes in a feedback manner even in the event of a power failure or an emergency stop. The steering brake 6 is engaged to increase the braking force. Thus, the traction sheave is strongly braked, while the ropes, counterweight, car and other masses suspended above them tend to continue their motion. If there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com