Impact resistance test device for diamond compound sheet

A technology for a diamond composite sheet and a test device is applied in the field of impact resistance test devices for diamond composite sheets, which can solve the problems of backward detection methods for the impact performance and impact resistance of the bound diamond composite sheet, and achieves simple structure, high degree of automation, and high measurement efficiency. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

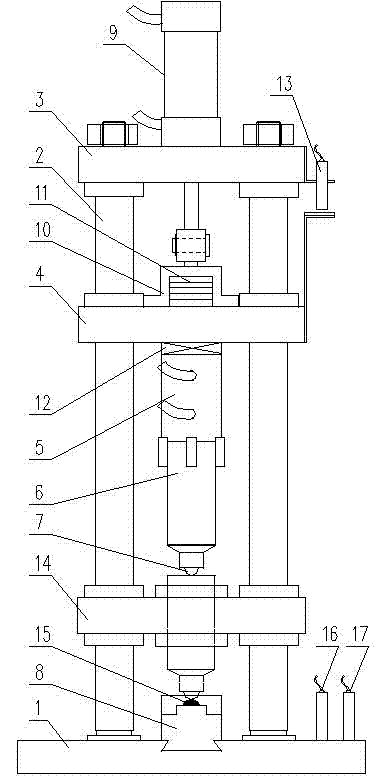

[0013] like figure 1 The diamond composite sheet impact test device shown includes a guide post 2 and a top plate 3 and a bottom plate 1 fixed on the upper and lower ends of the guide post 2. A cylinder 9 is provided at the upper center of the top plate 3, and a clamp 8 is provided on the bottom plate 1. . The guide post 2 is provided with a movable plate 4 slidingly fitted therewith, and the upper part of the movable plate 4 is provided with a connecting bracket 10 , and the connecting bracket 10 is connected with the piston rod of the cylinder 9 . A stepping motor 11 is arranged in the connecting bracket 10, and the stepping motor 11 is connected to the pneumatic chuck 5 at the bottom of the moving plate 4 through an output shaft, and the pneumatic chuck 5 is installed on the bottom of the moving plate 4 through a bearing 12. A drop hammer 6 is assembled in the pneumatic chuck 5, and the drop hammer 6 corresponds to the fixture 8. A punching ball 7 is arranged at the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com