Grill and SMD device containing the same

A patch device and grill technology, which is applied in the direction of electrical components, electric switches, circuits, etc., can solve the problems that the guide bar hinders the rotation of the placement plate and cannot automatically fall to the placement plate, so as to reduce the operation process, reduce labor costs, Effect of labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

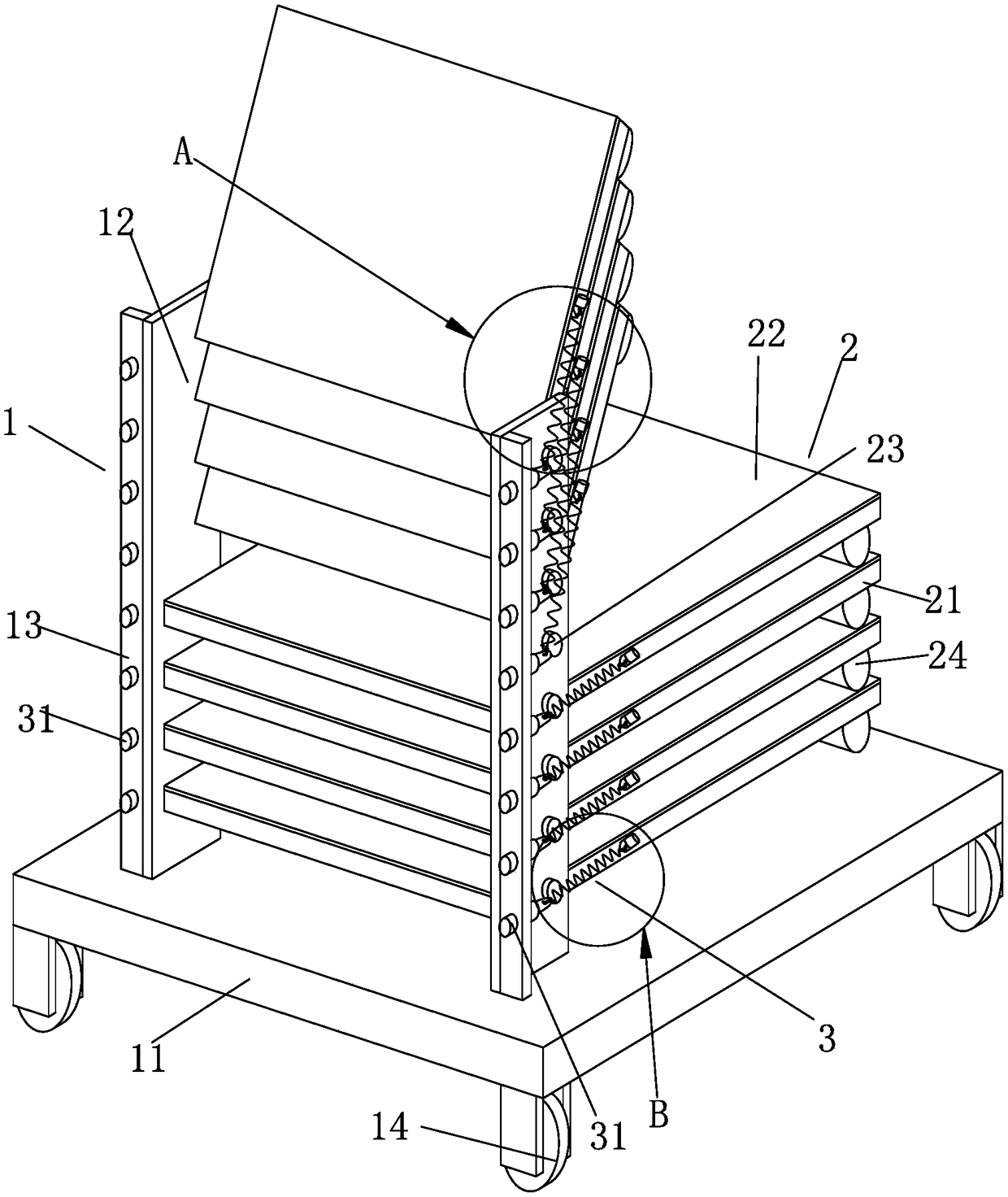

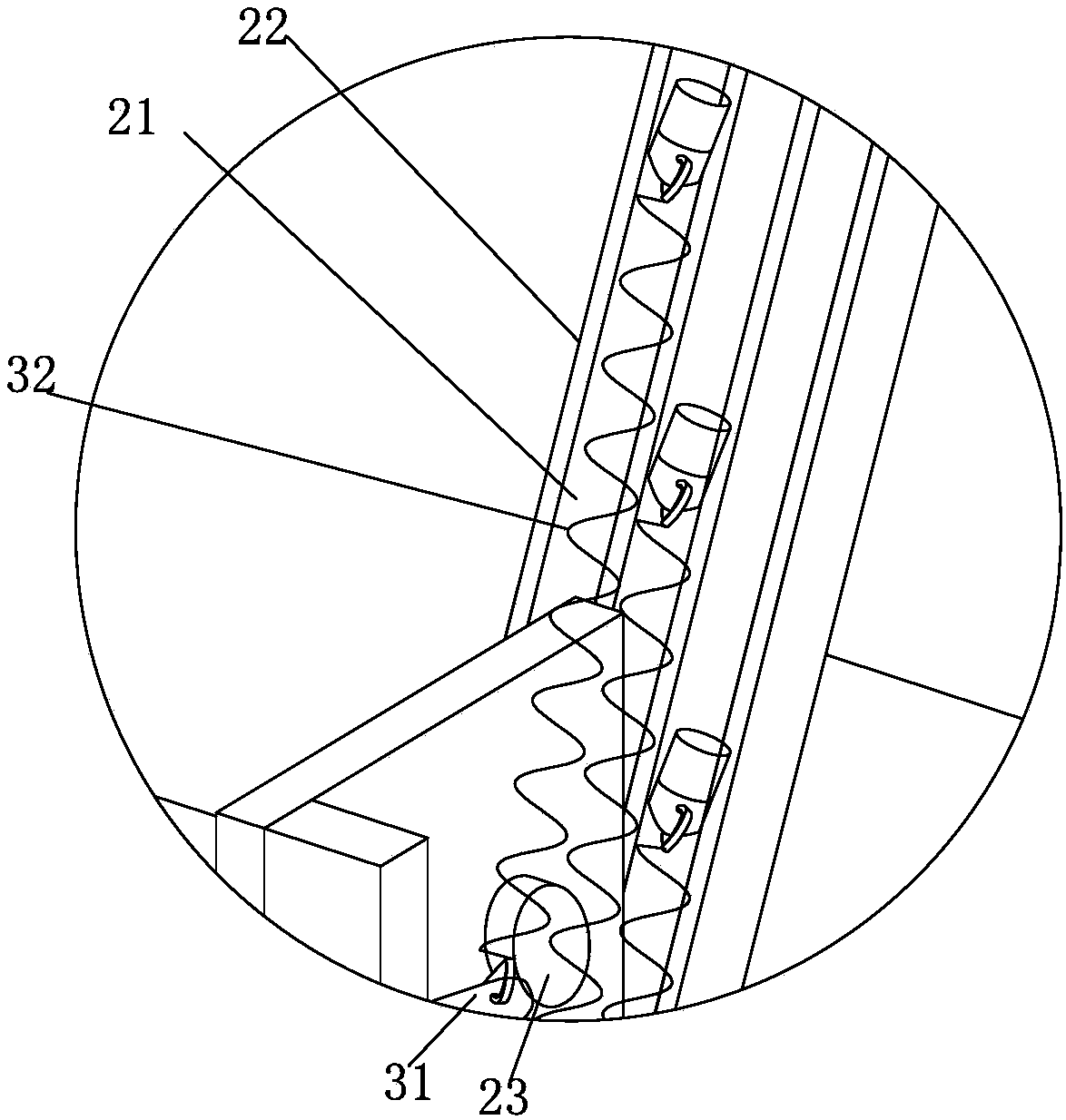

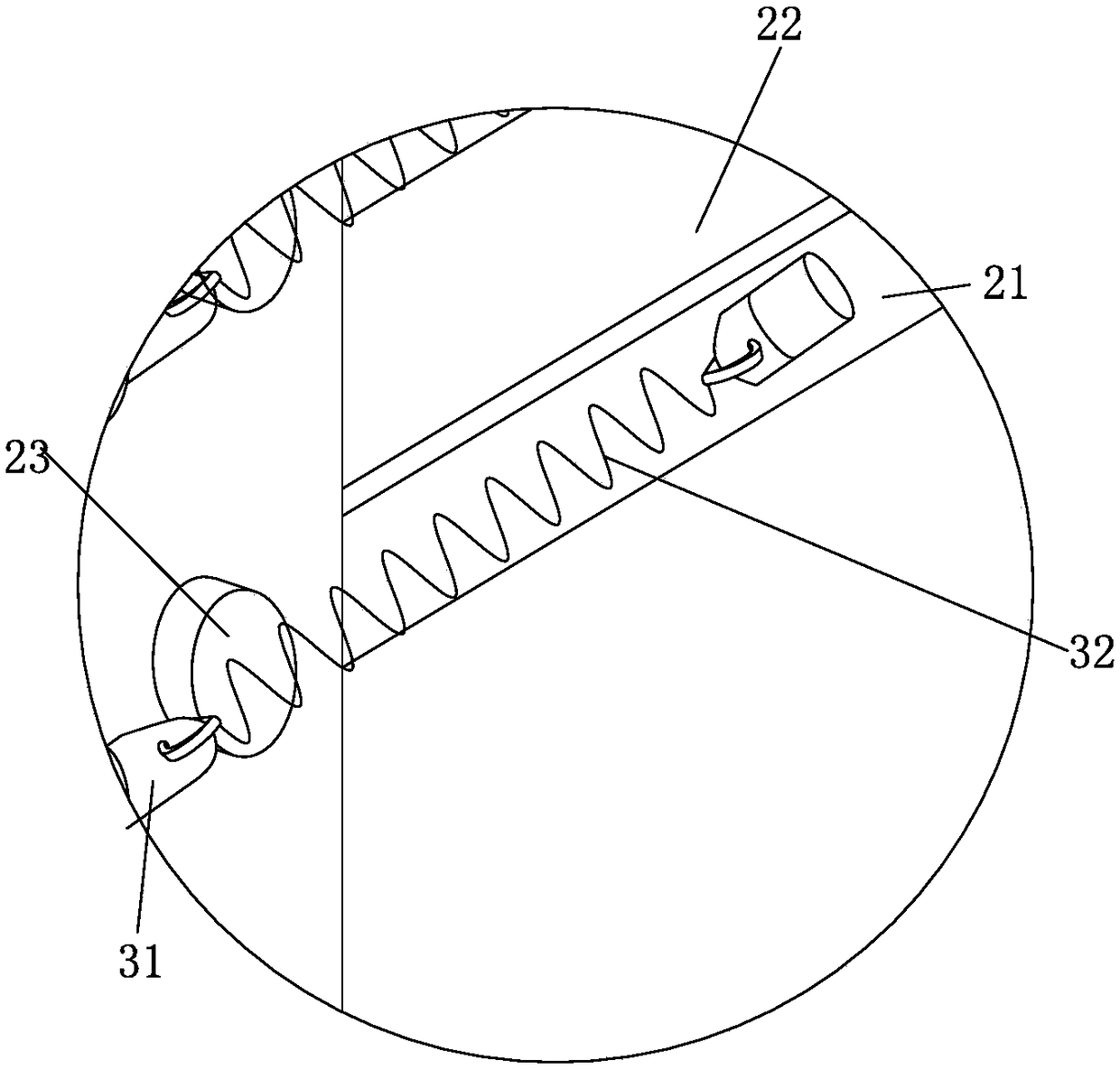

[0054] The difference between the first embodiment and the first embodiment is that, in order to facilitate the process of pasting the spacer on the die, this embodiment proposes a patch device.

[0055] A patch device in this embodiment includes the grill and the conveyor belt 4 in Embodiment 1, the input end of the conveyor belt 4 is arranged next to the output end of the transmission structure of the ink coating device in the clean room, and the output end of the conveyor belt 4 is close to the dust-free The outdoor grill is set, and a patch workbench 5 is set beside the conveyor belt 4 . When in use, the drive belt outputs the dies just produced. Since the placement workbench 5 is located next to the conveyor belt 4, the operator who is placing the patch can get the die dies at the output end of the conveyor belt 4. When the operator has no time to process, the operator Cutting dies that cannot be processed in the future are transferred from the conveyor belt 4 to the gril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com