Steel pipe threading machine

A wire machine and steel pipe technology, applied in the direction of mechanical equipment, connecting components, coatings, etc., can solve the problems of high labor intensity, hidden safety hazards, low efficiency, etc., achieve high efficiency and automation, reasonable structural design, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

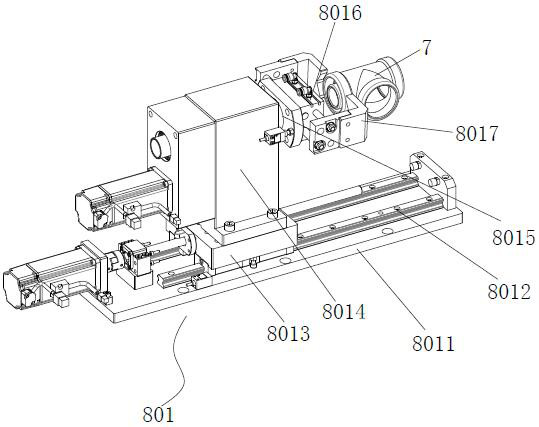

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, and specific implementation methods will be given.

[0031] Such as figure 1 As shown, the steel pipe screwing machine of the present invention is mainly used for installing a two-way or a three-way joint on one or both ends of the steel pipe after threading. The machine head and the machine head, the machine head moves horizontally along the guide rail set on the frame of the screwing machine by moving the bottom supporting plate, so as to adjust the distance from the fixed machine head, and the fixed machine head is fixed on the screwing machine through the fixed bottom supporting plate. On the frame of the machine, the parts with the same structure are symmetrically arranged on the movable bottom pallet and the fixed bottom pallet, so as to realize the adjustment of the distance between the motor head and the fixed machine head according to the length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com