Double-draw shaft-inclined roadway combined layered construction method for high and large chamber

A layered construction and combined technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of high construction cost, complicated support procedures, and difficult construction, so as to reduce construction cost and simplify the slag discharge process , good ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

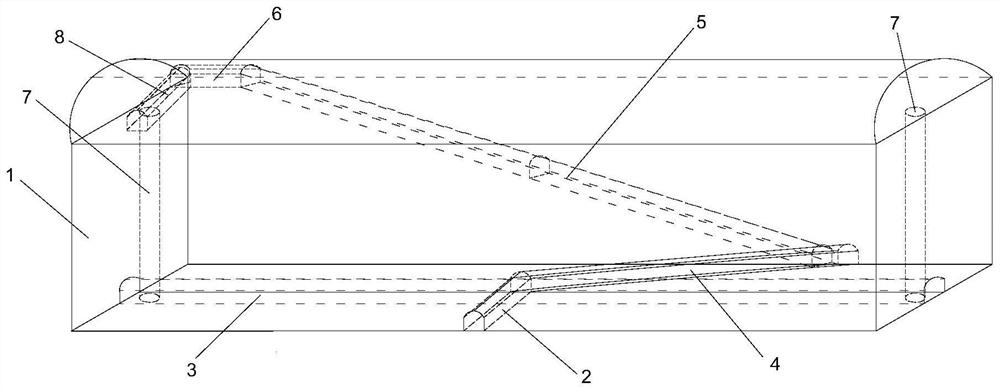

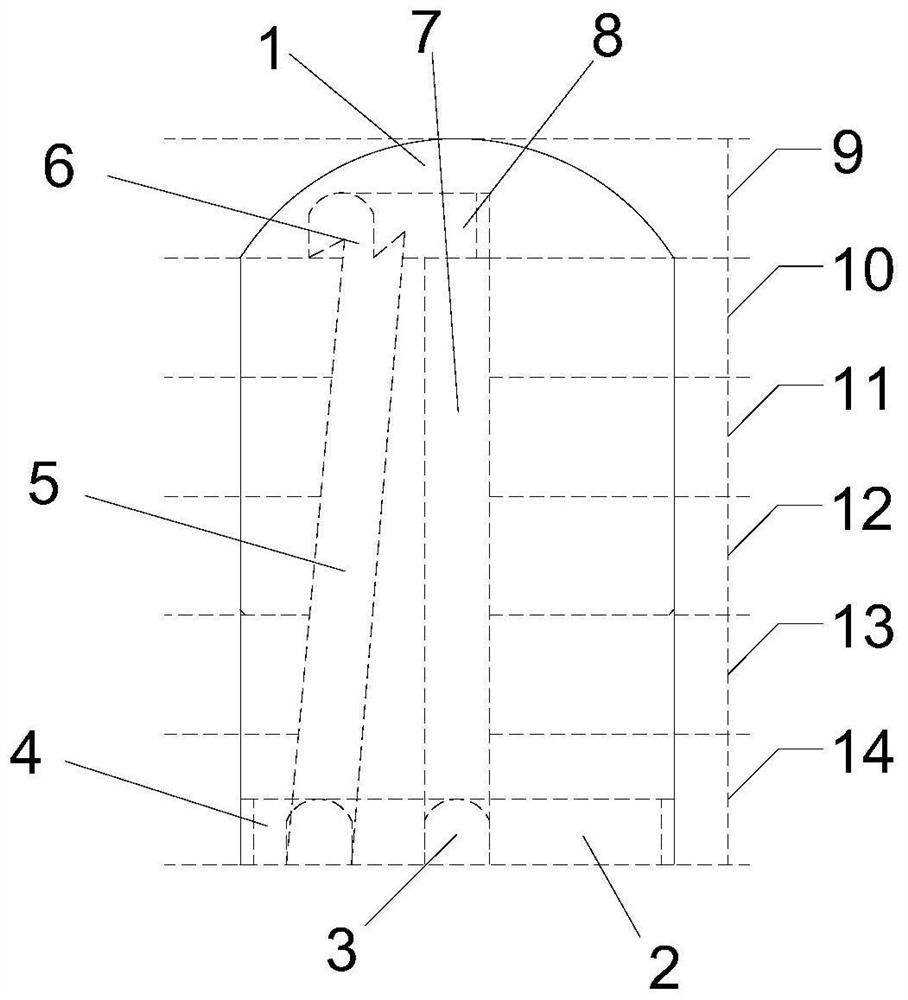

[0026] Such as Figure 1-Figure 3 As shown, a double chute-inclined roadway combined layered construction method with tall and large chambers comprises the following steps:

[0027] a. Determine the length, width, height and arch height of chamber 1 according to the construction requirements of chamber 1. The length of chamber 1 exceeds 100m, the height exceeds 30m, the width exceeds 15m, and the arch height exceeds 6m. The arching height of chamber 1 is designed according to 1 / 3~1 / 4 of the width of chamber 1. If the height is 6.66m~5.0m, the arching height of chamber 1 is determined to be 6.5m.

[0028] b. Determine the layered height of chamber 1 according to the height of chamber 1.

[0029] Due to the large span and length of chamber 1, the division of layer heights of chamber 1 should meet the requirements of construction and the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com