Method of forming isolation structure of semiconductor device

An isolation structure and semiconductor technology, applied in semiconductor/solid-state device manufacturing, solid fuel, special form of dry distillation, etc., can solve problems such as difficult to use, difficult to fill trenches in gaps between HDP oxide layers, and difficult to fill trenches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

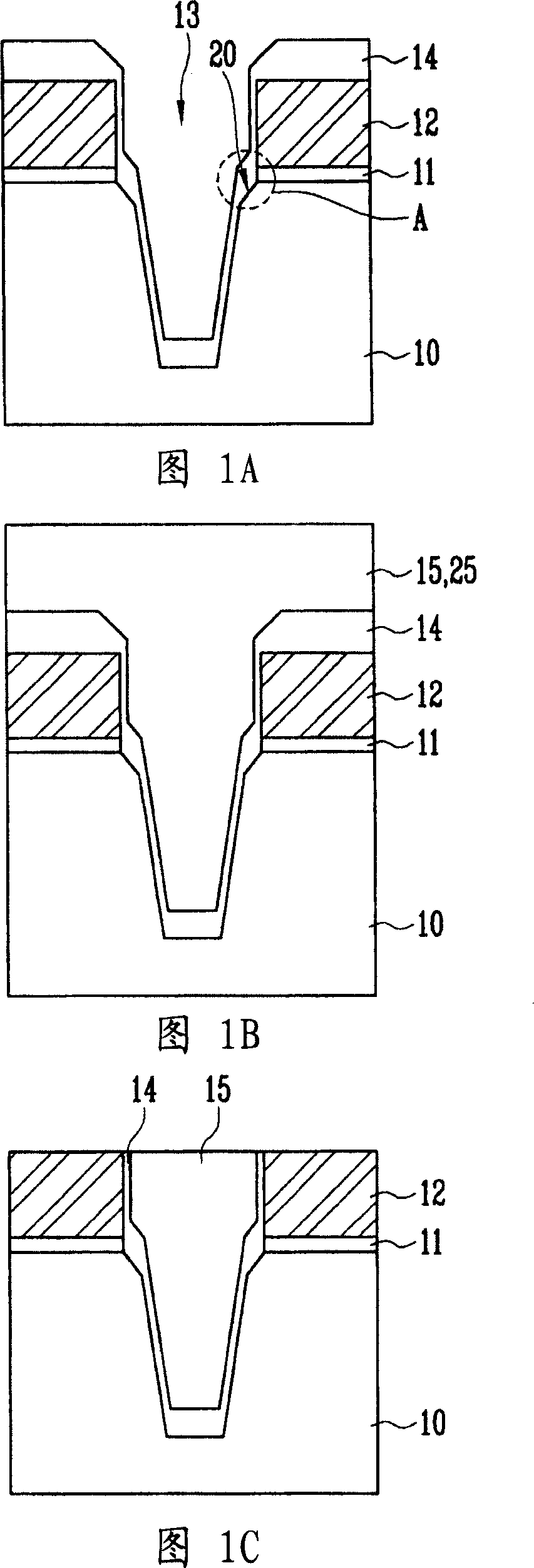

[0012] 1A to 1E are cross-sectional views of a semiconductor device for illustrating a method for forming an isolation structure of a semiconductor device according to an embodiment of the present invention. The accompanying drawings show embodiments of the present invention applied to a self-aligned shallow trench isolation (SA-STI) structure.

[0013] As shown in FIG. 1A, the tunnel oxide layer 11 and the polysilicon layer 12 for the floating gate are sequentially formed on the semiconductor substrate 10. By photolithography, the polysilicon layer 12 for the floating gate, the tunnel The through-oxide layer 11 and the semiconductor substrate 10 are etched to a specific depth to form isolation trenches 13 . Then, a first insulating layer 14 is formed on the surface including the isolation trench 13 . A high density plasma (HDP) oxide layer having a thickness of 100 to 2000 angstroms (A) is preferably formed as the first insulating layer 14 . The first insulating layer 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com