Aluminum alloy sheet for lithographic printing plate and method of producing the same

A lithographic printing plate, aluminum alloy plate technology, applied in printing, metal rolling, printing technology, etc., can solve the problems of reduced production efficiency, increased manufacturing cost, etc., to achieve improved production efficiency, uniform occurrence of pits, heavy The effect of uniform crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

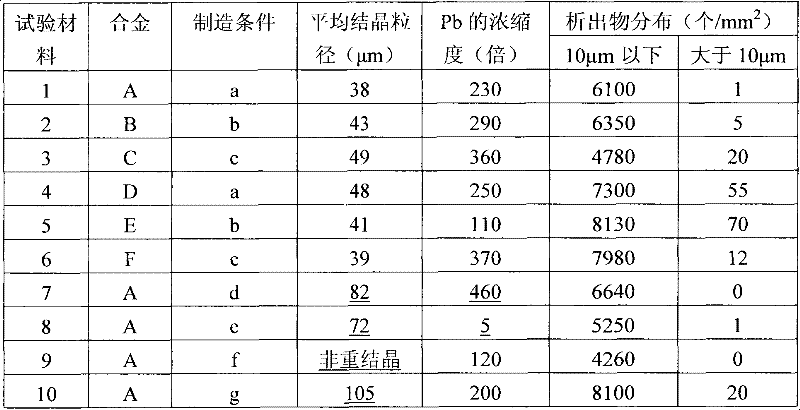

[0032] Embodiment 1, comparative example 1

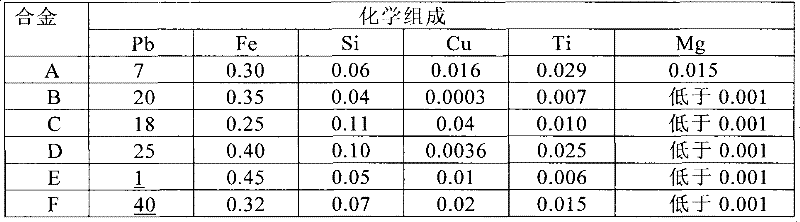

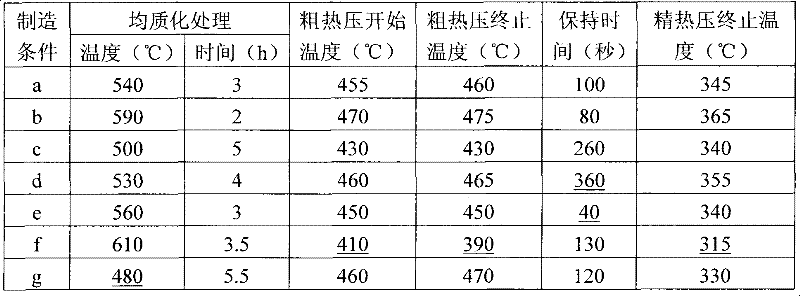

[0033] The aluminum alloy having the composition shown in Table 1 was melted and cast, and each rolled surface of the obtained ingot was cut by 5 mm / one side so that the thickness became 500 mm, and each ingot was homogenized under the conditions shown in Table 2. Texturization treatment, hot rolling, and finish hot rolling to make the thickness of the plate reach 3mm, and coil it into a coil. After the hot rolling, cold rolling was performed without intermediate annealing to obtain a cold-rolled sheet having a thickness of 0.3 mm. In addition, in Tables 1-2, those which deviate from the conditions of this invention are underlined.

[0034] Table 1

[0035]

[0036] "Remarks" only Pb unit adopts ppm, others adopt mass%

[0037] Table 2

[0038]

[0039] "Remarks" Holding time: the holding time after the end of rough hot rolling and before the start of finish hot rolling

[0040] Using the cold-rolled material as the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com