Blade of a wind turbine

A technology of wind turbines and blades, applied to wind engines, wind turbine components, blades, etc., can solve expensive and time-consuming problems, achieve the effect of reducing weight, reducing quantity, and avoiding repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

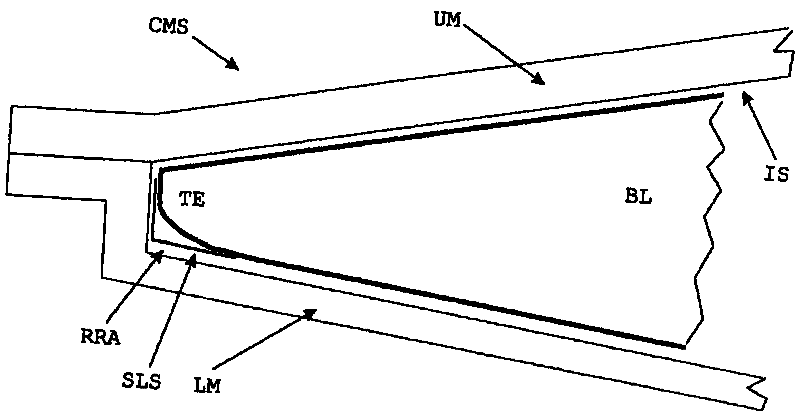

[0031] figure 1 The arrangement created to be part of the closed mold system CMS is shown by means of a cross-sectional view.

[0032] The lower mold LM is used in the VARTM process to support the blade BL of the wind turbine.

[0033] The structure of the blade BL is built by fibers, mats, balsa wood, prefabricated parts, bladders filled with any kind of shaped material etc. (not shown in detail here) as described above. These elements thus form the different layers of the wind turbine blade.

[0034] Therefore, the lower mold LM is used to support this "sandwich structure" of the blade BL.

[0035] The upper mold UM is connected to the lower mold LM, and the upper mold UM is also used to build the closed mold structure, as described above.

[0036] The cross-sectional view shows the trailing edge TE of the blade BL.

[0037] Due to the inner surface IS of the closed mold structure and due to the specific shape of the trailing edge TE, a resin rich area RRA will be create...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com