Hectowatt collimation type isolator

A collimating and isolator technology, used in instruments, optics, nonlinear optics, etc., can solve the problems of large insertion loss, poor heat dissipation, and low isolation, and achieve the effect of improving stability and heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

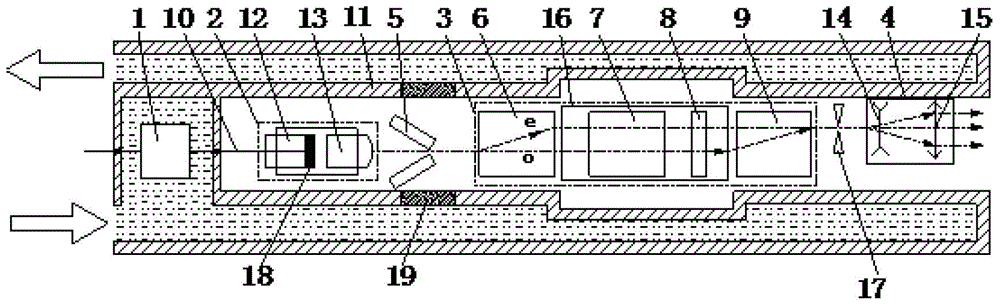

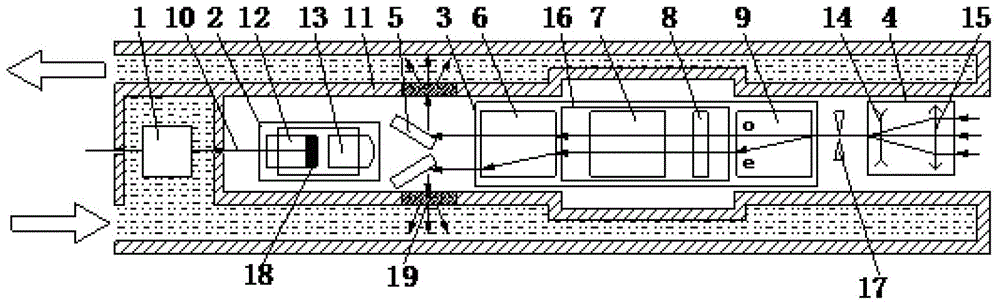

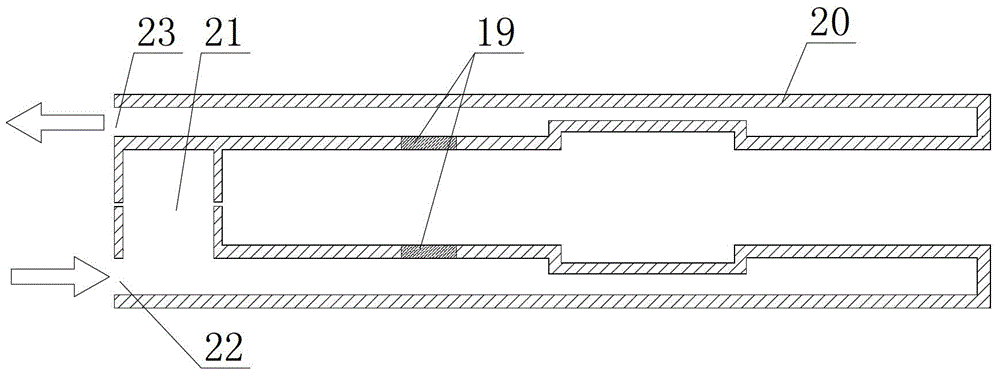

[0027] Embodiment 1 of the present invention: as figure 1 As shown, a hundred-watt-level collimating isolator includes a mold stripper 1, a fiber collimator 2, an isolator core 3, and a beam expander 4 arranged sequentially along the incident optical axis of the forward light. The device 1 is connected with the fiber collimator 2 through the optical fiber 10, and there are two mirrors 5 arranged symmetrically between the fiber collimator 2 and the isolator core 3; the stripping device 1, the fiber collimator 2, The isolator core 3 , the beam expander 4 and the reflector 5 are all arranged in the water-cooled packaging device 11 . The included angles between the two reflecting mirrors 5 and the optical axis are both 45°.

[0028] The fiber collimator 2 includes an optical fiber pigtail 12 and a lens 13 , the optical fiber pigtail 12 is connected to the optical path of the isolator core 3 through the lens 13 , and an end cap 18 is provided at the tail of the optical fiber pigta...

Embodiment 2

[0031] Embodiment 2 of the present invention: as figure 1 As shown, a hundred-watt-level collimating isolator includes a mold stripper 1, a fiber collimator 2, an isolator core 3, and a beam expander 4 arranged sequentially along the incident optical axis of the forward light. The device 1 is connected with the fiber collimator 2 through the optical fiber 10, and there are two mirrors 5 arranged symmetrically between the fiber collimator 2 and the isolator core 3; the stripping device 1, the fiber collimator 2, The isolator core 3 , the beam expander 4 and the reflector 5 are all arranged in the water-cooled packaging device 11 . The included angles between the two reflecting mirrors 5 and the optical axis are both 40°.

[0032] The fiber collimator 2 includes an optical fiber pigtail 12 and a lens 13 , the optical fiber pigtail 12 is connected to the optical path of the isolator core 3 through the lens 13 , and an end cap 18 is provided at the tail of the optical fiber pigta...

Embodiment 3

[0035] Embodiment 3 of the present invention: as figure 1 As shown, a hundred-watt-level collimating isolator includes a mold stripper 1, a fiber collimator 2, an isolator core 3, and a beam expander 4 arranged sequentially along the incident optical axis of the forward light. The device 1 is connected with the fiber collimator 2 through the optical fiber 10, and there are two mirrors 5 arranged symmetrically between the fiber collimator 2 and the isolator core 3; the stripping device 1, the fiber collimator 2, The isolator core 3 , the beam expander 4 and the reflector 5 are all arranged in the water-cooled packaging device 11 . The included angles between the two reflecting mirrors 5 and the optical axis are both 50°.

[0036] The fiber collimator 2 includes an optical fiber pigtail 12 and a lens 13 , the optical fiber pigtail 12 is connected to the optical path of the isolator core 3 through the lens 13 , and an end cap 18 is provided at the tail of the optical fiber pigta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com